I end up with a lot of mostly unusable scrap because I mostly make round things.

So, in the name of learning new things, I decided to see if I could use those scraps to test things. Enter… the minibox!

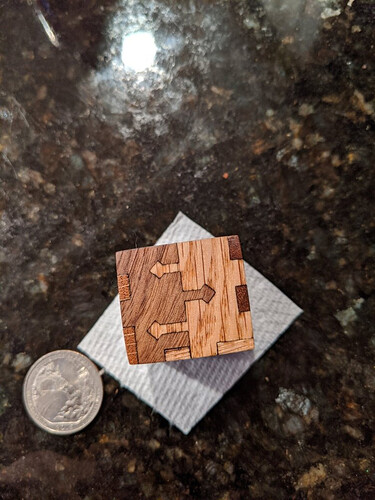

It’s small. 24mm interior. Which meant the first thing I was testing was the limits of the laser and the strength of the wood. Which I combined with trying to make it entirely pressure fit. Because of course I did.

This led to some interesting problems and balancing acts. Like how to adjust for kerf for the outside curves, the inside curves, and not overadjust for the places where two outside curves would be running into eachother for the pressfit.

The planar join was fairly easy. I’ve made myself a spreadsheet of woods with max/min kerfs.

I did a standard flip on one side so the two slopes met up and you get a good edge inside and outside.

But that means the kerf on one half of a side’s joins is the minimum kerf for that wood, and the other half is the maximum for a second wood. And they slope opposite directions. Which led to some testing, and breaking.

Cracked a couple before I got one that would work. Oak likes to crack along the grain when pushed sideways. Full disclosure, this is actually the second attempt at a minibox, the first resulted in…

But I learned a fair bit from it. Changed my kerf adjustment method, simplified my planar join so I wasn’t dealing with QUITE as many variables.

The corners on this box are SUPER tight, because I wasnted to use one kerf correction for each piece, not try to fiddle with variable ones.

But, overall, a really successful experiment. Learned a bunch, improved my skills, tested a planar join, and didn’t use any wood that I would have for something else! Will definitely be making more of these to test methods.