Okay, so as some of you know, there has been this craze of lasering ceramic tiles. I got kind of sort of obsessed with doing them and kind of went overboard doing a whole bunch, some listed here and my previous process up to this point: Ceramic Tile Mania! - #38 by raymondking32

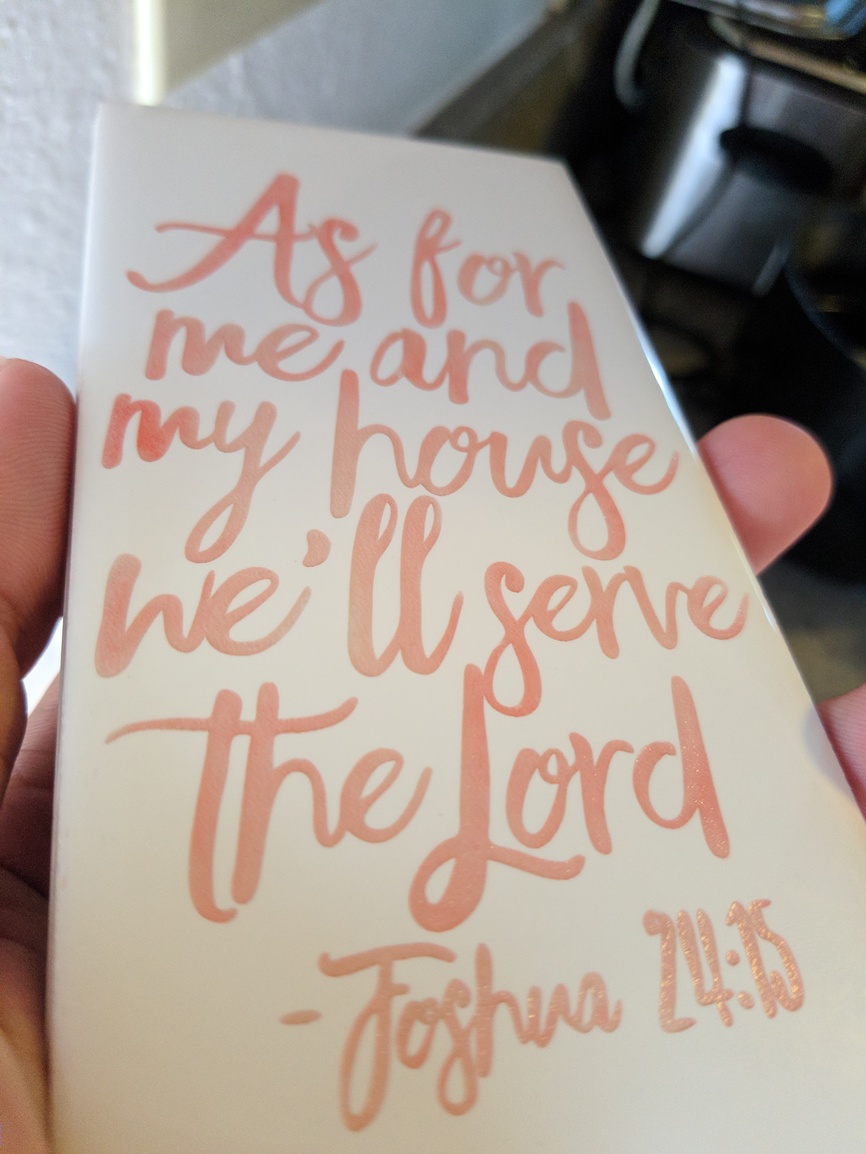

That doesn’t even show all of the tiles I’ve done that I ran out of space for on my desk ![]() Anyway, I’ve been considering what I could do to upgrade them. I used the stand designed by @Janerlea, settings: Manual height of .3", Speed 1000, FULL POWER, and 450LPI, and then would color them in with Sharpie markers. The cleanup process consisted of a regular paper towel with a dab of windex , and so long as the lines were thin enough, very little touchups were required. The broader expanses of etched tile that there is, you will lose a bit of color in those areas if you aren’t careful.

Anyway, I’ve been considering what I could do to upgrade them. I used the stand designed by @Janerlea, settings: Manual height of .3", Speed 1000, FULL POWER, and 450LPI, and then would color them in with Sharpie markers. The cleanup process consisted of a regular paper towel with a dab of windex , and so long as the lines were thin enough, very little touchups were required. The broader expanses of etched tile that there is, you will lose a bit of color in those areas if you aren’t careful.

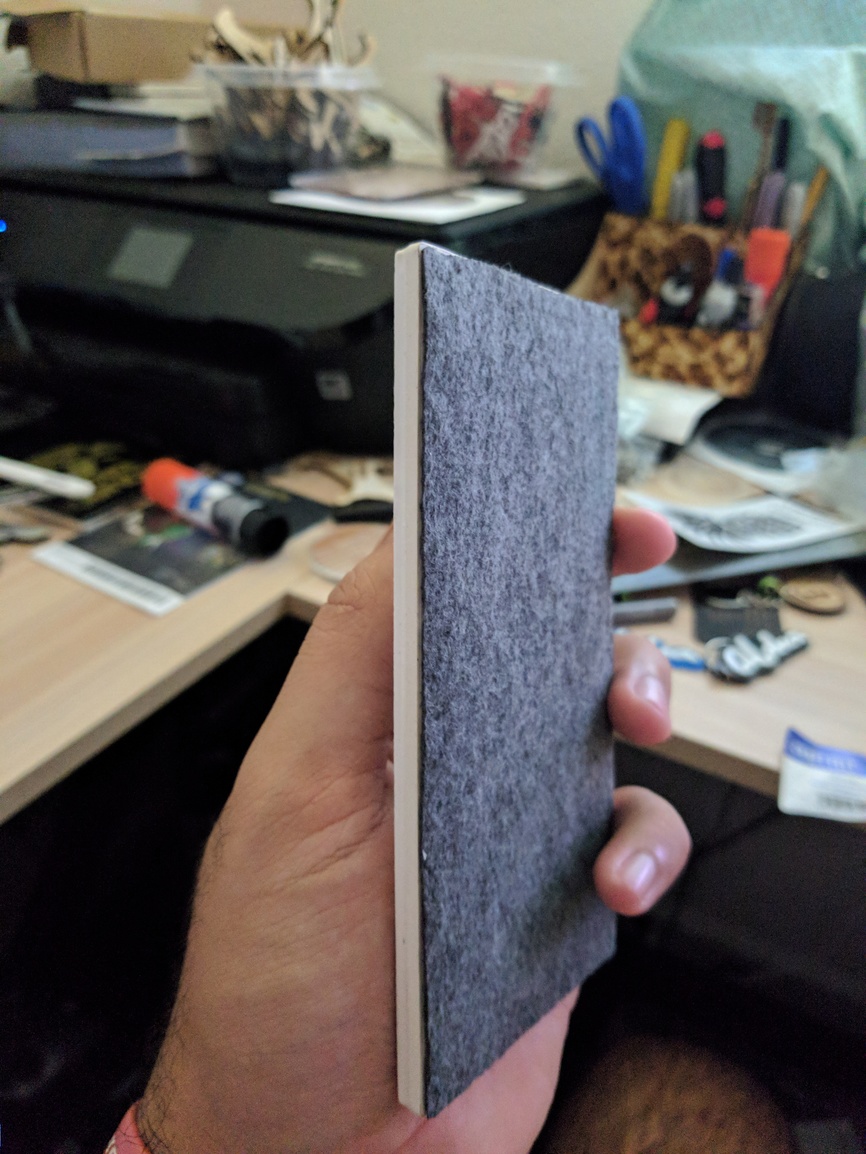

Moving on; I wanted, since the beginning, to put some soft backing to avoid scratching surfaces if I were to also sell these as coasters, but also to hide the back of the tile as I’m a stickler for details. On a personal level it bugged me to have just a gritty unglazed back rubbing against the stands I made. I went to a couple of craft stores to search for some felt or cork, but settled on cheap 9"x12" felt I found at Walmart (excellent stuff, really). Cut it up on the laser (not entirely sure it’s safe to do) and hot glued it to the back of the tiles.

I originally used E6000 glue, but it absorbed into the tile and felt too easily. I opted for hot glue because it creates a middle ground between the two. What I found works best is to do one line of glue on one side of the tile, and quickly press the felt into that, then repeat for the remaining 3 sides. This is because my glue was drying quicker than I expected, so it was easier to do a side at a time.

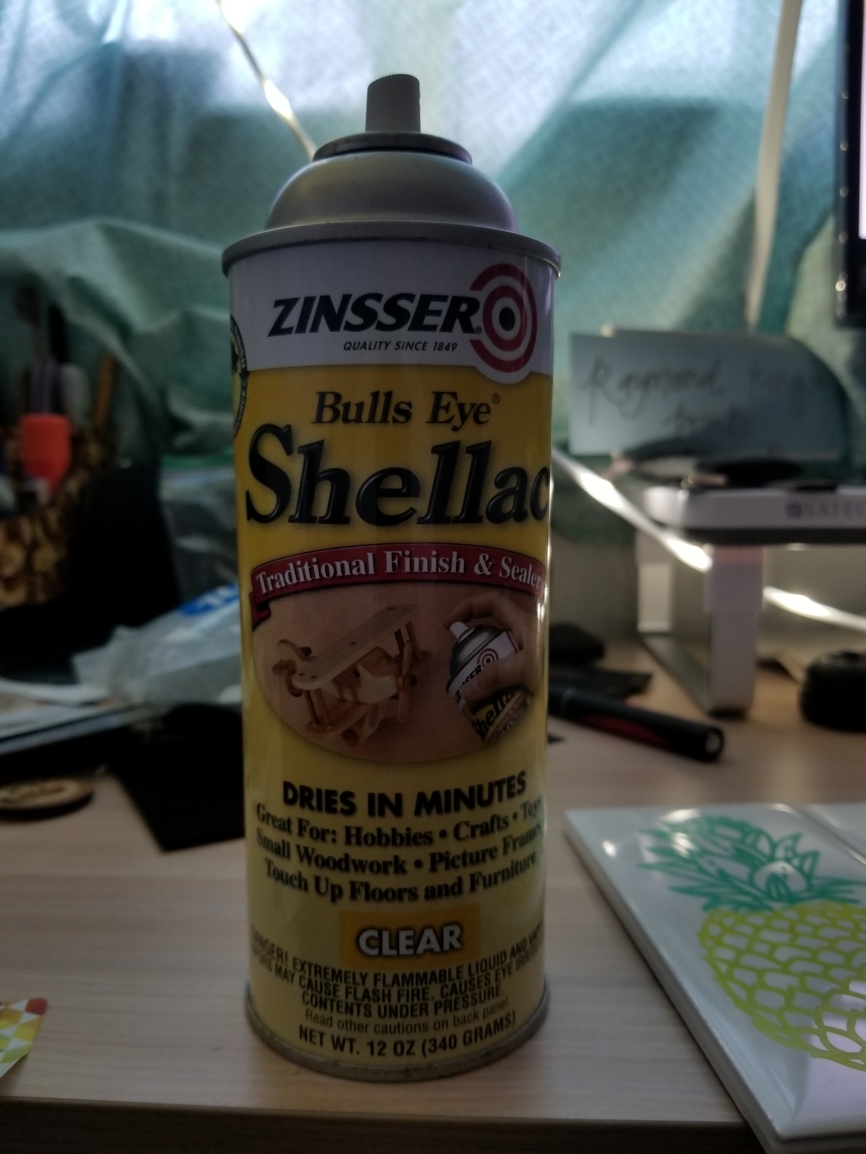

That was today’s main project. I have experimented, and need to do a couple of more tests, with sealing the color with spray can shellac

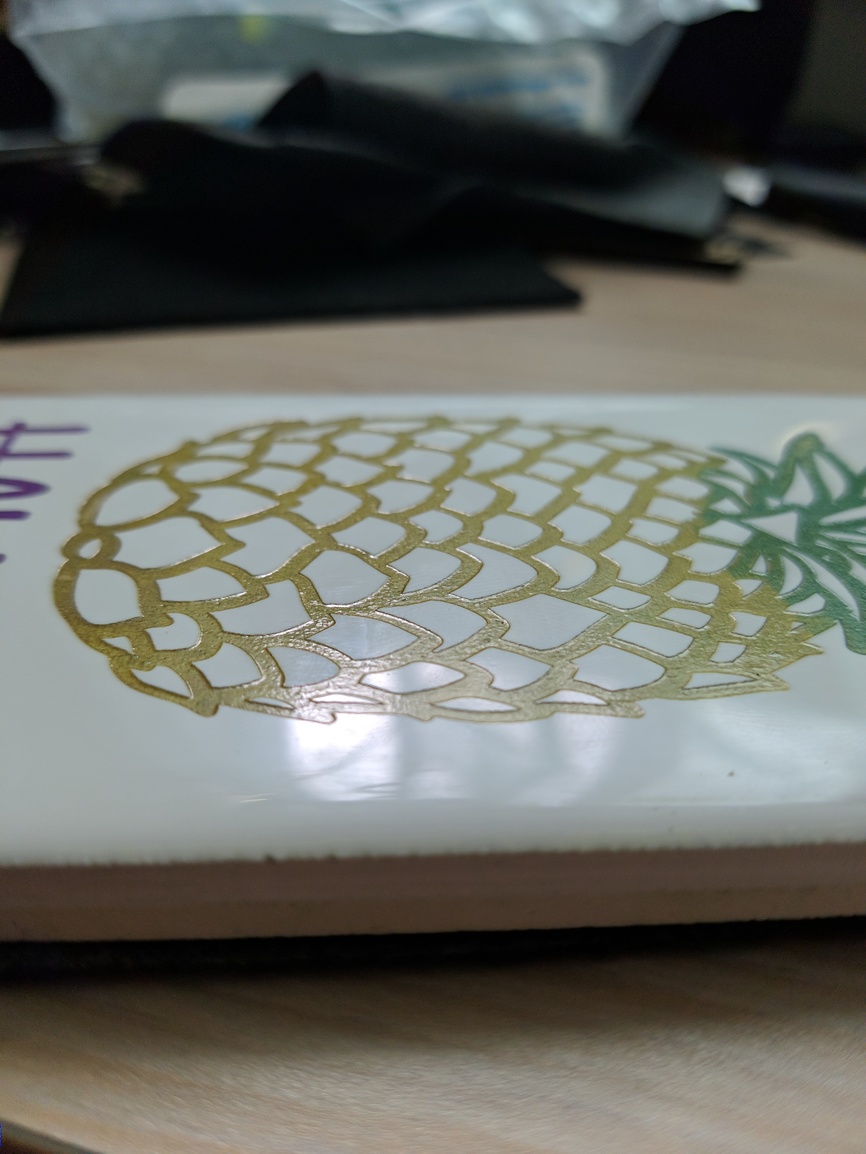

I’ve done this with masking and without and I’ve got two separate results because of it. The first time I did it without shellac, and it required me to do a lot of scraping with a razor blade (I just ordered a window scraper style to ease the finger cramping and add safety). It gave me a stellar result afterwards, but I wanted to know if masking the tile first then sealing it would be easier. It certainly is, but I’m not sure if it’s because of the masking, the specific color we used, or what, but the tile absorbed the color differently. In result of this when I sprayed it, the color lifted and created a sort of watercolor effect

I really like it, but it was just unexpected. I’ve only done one with the masking and shellac, so I can’t say if it will continue to do this, but the other ones I’ve sealed without the masking did not have the same effect

I’ll have to do a few more tests, but so far I’ve loved the results. Here’s a close up pic of one that isn’t sealed to show the difference in texture.

In conclusion, I’m really excited about where I can go from here. Currently I’m selling the tiles for $20 individually, and considering making them a set of coasters for $50, but I want to dial down my process some more. I’ve made a handful of others things that I want to share, but that will have to wait for a future post. You can also check out my Instagram for some of the projects I haven’t shared yet, and if you watch my story, you can see my process: Ray’s Prints

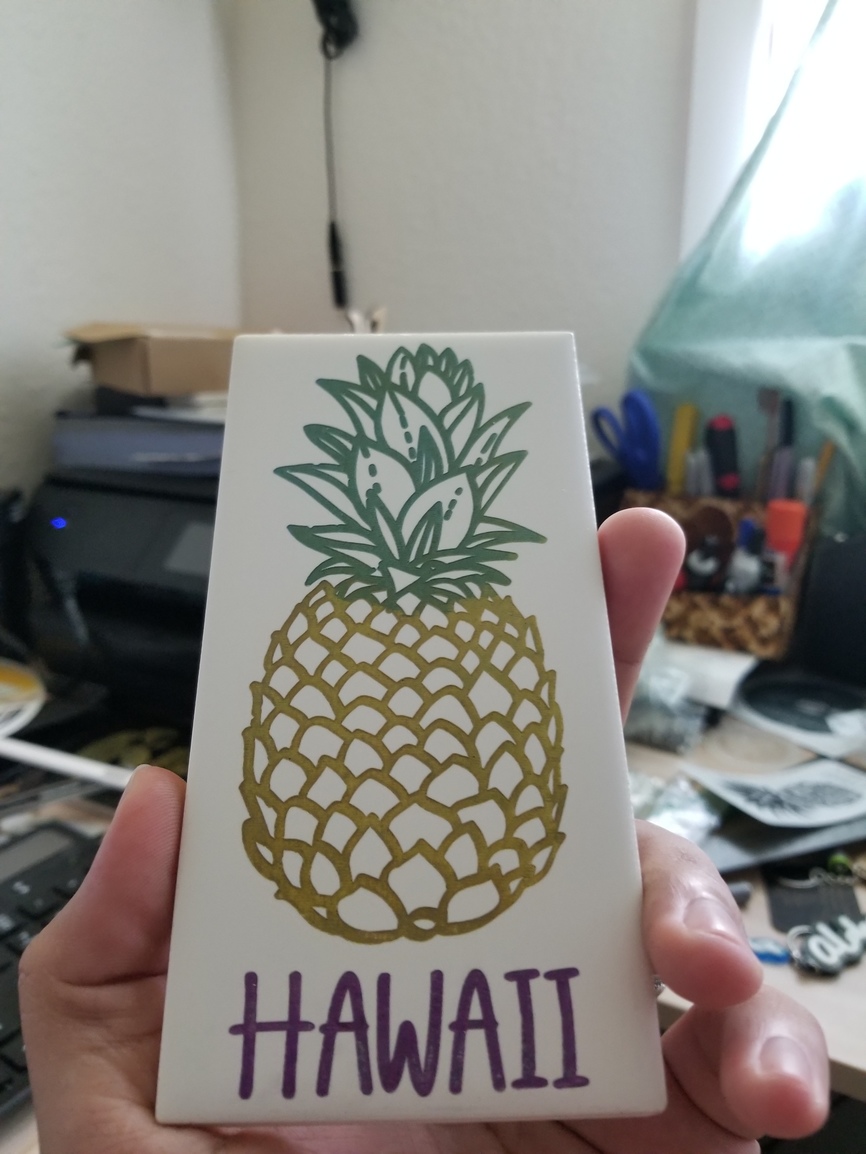

Bonus shot of my favorite tile I’ve done, based off the artwork of an artist I follow on Instagram: