I need to move my Glowforge but have long-since gotten rid of the box it came in.

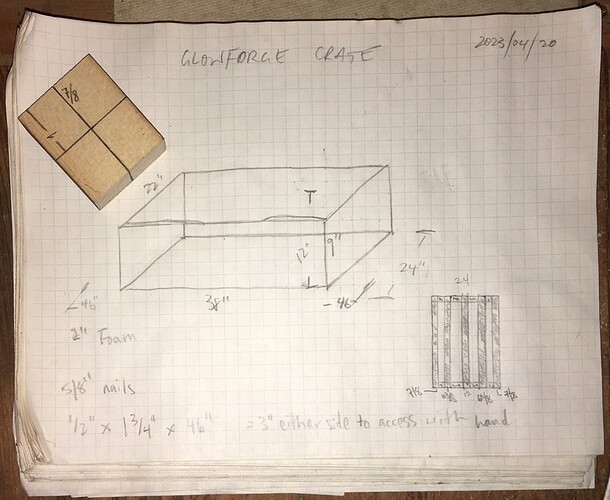

Here are plans and pictures of the crate I built. Sorry to my Canadian compatriots; this is in imperial not metric. Sometimes it’s just easier to work with the dimensions you get at the lumber yard.

Here’s the finished crate.

I used 1/8" plywood for the bottom, sides, and top. I wanted it light but sturdy when braced. I ripped 2" x 1 3/4" strapping and then made story sticks to make the measurements consistent.

I used a brad nailer to fasten everything as I built, then reinforced the stress points at the end and bottom with counter-sunk screws.

I wanted to make sure to leave room on either end to fit hands for lifting in and out. The front and back clearance is minimal.

There is a floating floor over the lap-jointed floor strapping. I cut up flat pool noodles and laid them between the strapping and a false floor, which was another piece of 1/8" plywood. The Glowforge sits on the false floor so shocks are dampened.

I also have some pipe insulation cut in half across the top and a 1/8" piece of plywood there too. The idea is to dampen or distribute shocks and prevent the glass from shattering.

I figure I’ll use foam or something like the original packing pieces to dampen the ends. The lid has clasps so it’ll stay on.

There are carry holes on either end. I probably could have added clasps at the sides to reinforce, but I needed it done, not perfect.

I think I still have the orange pieces for the insides, and if not I have the manual and unboxing pictures so I’ll have some reference to brace the innards.

See also: moving a glowforge cross country

[Update 2023-05-24] the move went well. I probably should have had two hand holes at either end to make it easier to carry but this still did the trick. I used bubble wrap at either end and some firm foam back and front and just hoped it would be ok. Next up: unboxing and setting back up to see if it worked.