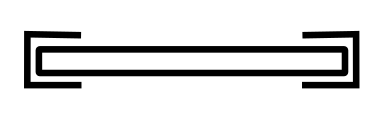

When I first got my glowforge, I cut some MDF with a hole in it to fit in my window to use as a vent. But I could not just place it in the window, because there is a lip all around the window. From the top, it kind of looks like this:

A rigid piece of wood could not be put in it. If I used wood that was thin enough to flex, it would not insulate much.

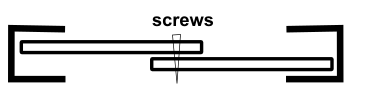

So I had to make it in multiple parts, and put each part in place, and screw them together in place.

So it looked like this:

It worked, but it was pretty “permanent”. To remove it I would have to remove the screws and it took more time than I wanted.

It was not a good solution.

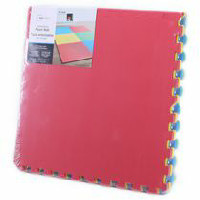

I was playing with foam floor mats (making weapons for the kids), when a light bulb came on. Why not use these for the vent? You can find these mats at any hardware or walmart.

So I took one, cut it to size with an exacto knife, cut a hole in it for a vent fan with the exacto as well. I made 2 that were the same (so I could double up the layers). I made them fit snugly. It took me 10 minutes to make these, and they work like a charm!

They flex enough for me to put them in the window. They easily come out when I’m not using the GF. And they seem to be fairly well insulating, because I can’t feel a draft coming through the window at all. I think it was a “brilliant” use for this material!

Here’s what it looks like with the window closed:

I opened the window and took a top down picture.

It’s not see-through though. Anyone know where I can find see-through foam play mats?

I’m lucky that my window is not that big. Perhaps with a larger window, you could connect a few of these mats together, and cut those to size. If you use 2 layers, you could make sure the seams are at different places.

It works great for me. Your mileage may vary. ![]()

.

.

but so far I’ve just drunk the coffee.

but so far I’ve just drunk the coffee.