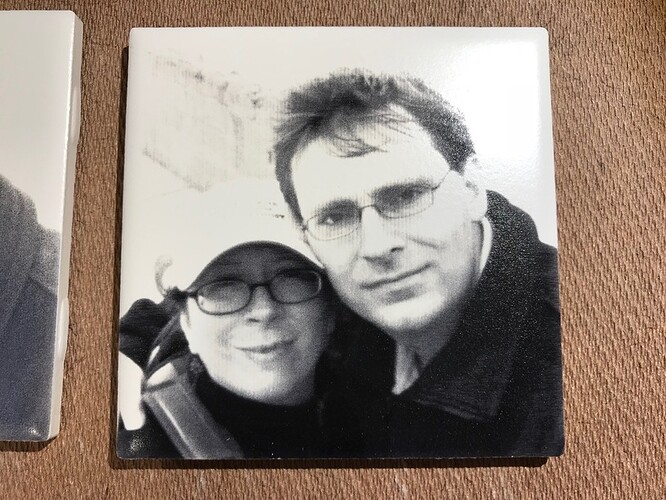

I’m really happy with the range of grey levels available with the 1000/100/450/vary power setting. In fact, the usual trick of cranking exposure way up to prevent the shadows from being lost resulted in an engrave that looks a lot like it does on the screen, with the highlights completely blown out. That’s a good thing, because it means I can probably get a better image by actually taking advantage of some mid-tones.

The only problem is a weird vertical banding. I don’t know if that’s something about the way the glaze is applied, or an artifact inherent to the Glowforge.

And we need to actually get a decent picture of the two of us.