This is fascinating to read about–I’m so glad you are posting all this. I don’t understand all the technical terms but I get the general gist, and I think everybody will benefit from this work. It can only be a great advantage to have a medical professional be as well trained as possible before they need to do these procedures on real people!

This is insanely fascinating. You ought to be on some kind of discovery channel program or biotech podcast. Or Tech. Or med.

It’s incredible.

I’m out of likes, too.

Thanks for sharing your projects here, since you aren’t on Discovery just yet.

I really feel privileged that you would take so much time to share all this with us. It’s so amazing what you are doing. Ditto with the TV show.

Really cool stuff! Kinda wild that the same materials I am using for making candy molds and car parts, you are using for lifelike human tissue simulations!!

Have you tried using fingers, or an EVA foam squeegee (sliced up foam flooring tile) to work the silicone into the power mesh? Just a hint from composites experience, when you stipple a liquid resin into fabric, it tends to drive air into the material as well. Brushing on a coat then gliding a finger or flexible soft squeegee over it will drive the liquid into the material.

Reynolds also has materials for thinning silicone, although it softens the durometer which may not work for your needs.

LOL, earlier this evening I checked in and saw the artery post. I was telling my husband all about it, and how fascinating it is to be able to learn about such things. He agreed that it was very interesting, so when I checked back and saw this post I thought he’d enjoy another update.

Me: “Oh wow! Now he’s making colons!”

Hubs: “Ecch, sounds like he’s going downhill.”

(ok, maybe you had to be there)

Utterly amazing.

No, but we will this morning! thanks for the tip. We like simple, and stippling is slow and painful, finger/squeegee sounds much faster!

Yeah, we have the thinners, but since there are a bazillion compounds they sell (love the wall-o-disks) we figured we’d try the disks to see if any work better before going crazy. We know there are silicones that work, since we have some commercial models ($$$$) that have ultrasound capability.

Tell him it is uphill (by about 6" from the iliac artery…)

And @Dan if you get me the GF quickly, I would have been able to make a way better curing rack. The challenge is that as the colon cures (this is fast-set - but still has about 30-40mins until it is solid) the stuff wants to flow to the dependent point. So I had to pathetically set up this made of a stylette and 2 mixing cups, as opposed to a rotisserie made of acrylic which I could have whipped out in a few mins on a GF powered by an arduino + gear motor I have for the artery project to drive the pump! This was painful to rotate…

@henryhbk would be a really good candidate for a pre-release unit.

Have you looked into using a Phantom Gel instead of silicone? The acoustic properties of the gel are very similar to human tissue. It should be easier to image through than silicone.

So the issue with ballistics gel (i.e. medical grade knox blox) is that they don’t last very long. With silicone we expect 1000 punctures with a needle prior to needing to be replaced. There are some articles on using a cross linked hydrogel, which we are looking into.

So another day, another organ (or a few). Today I brought the colon to the OR so my colleague Tom from CRS could try sewing on the colon from yesterday. Gets a B+ as it is a little firm, so we will try a softer silicone (Dragon Skin 10) on monday.

So first new organ today was we made a suturable artery. Now this is very different than the other artery, in that, that one was designed for radiology procedures, but this one is used to teach residents to suture (sew) arteries together (either a tear or attach either one end to another or in a T-shape as an implant).

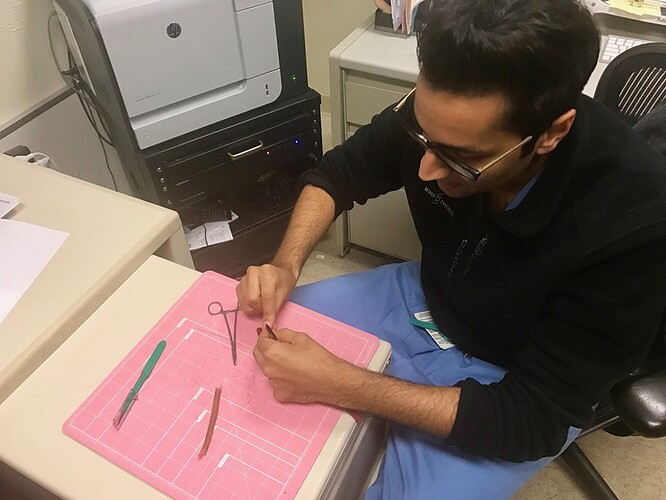

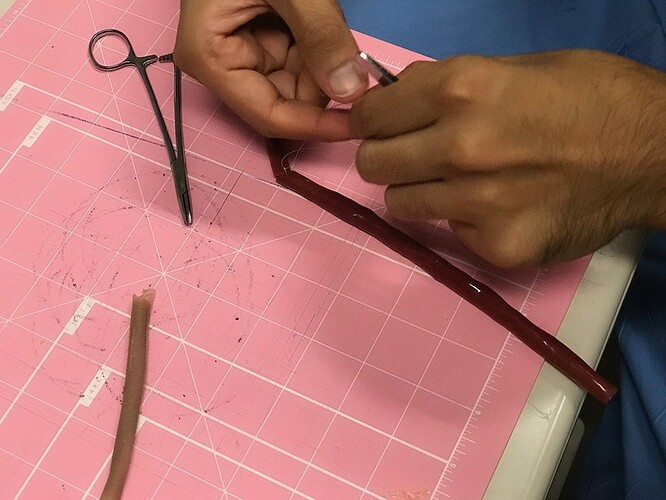

So for this we used Dragon Skin 10 Very Fast silicone (and no joke, it is very fast curing). So the setup is somewhat crazy, and we used a steel shaft in a drill and you coat it with a skim coat as it turns, then wrap the power mesh around it. You are slowly spinning the drill, apply more silicone while it is turning.

Then you add 3 drops of hardener (that I think was a mistake) to the mix (changes from pudding to peanut butter hardness in about 3 seconds) and apply the final coat. Then you apply the silicone solvent to your glove and smooth the whole thing. After about another minute you let it just sit for another 20 minutes and it is fully cured. There is a serious sense of urgency for this as it cures so fast, so definitely mis-en-place on this one!

drill setup

nice and shiny after the solvent

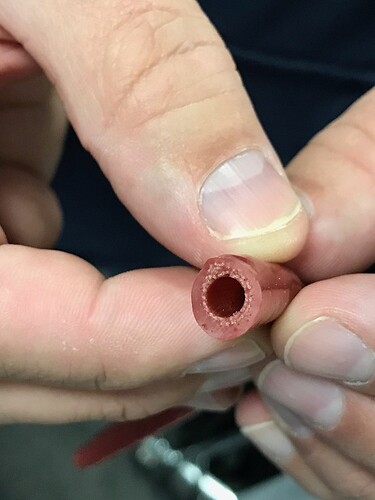

Powermesh in the vessel wall to grab the suture material. Now the teaching point here is if they don’t go perpendicular with the needle they will skeeve off the shallow material and the suture will tear out, just like a real artery (and that worked perfectly).

Soft but springy

Senior surgery resident giving it a spin. A bit thicker than we wanted, so monday will attempt it without the thickener agent.

A side incision all sewed up…

And second organ of the day, as I was showing off my artery in the lobby to a colleague, another came by who is one of our podiatry surgeons, and said “ya know what would be awesome? An achilles tendon!”

Never one to refuse a throw down, asked a few questions about what the achilles is like in real life, and ran off to the sim center. I had the idea of taking Dragon Skin 10 and just coating power mesh with it and very tightly rolling it. We tried two different thickness silicones, with and without the hardening agent.

30 minutes later in the podiatry clinic, showing it off. With hardener was like a brick, but without was super useful. $0.15 worth of material, and I can teach the podiatry chief residents to make it themselves for their interns next year…

The bottom one was the winner (might want to roll it a tad looser) so we will make little boards (hello GF!) to attach it too, with spring clips to sew the halves together (to simulate the ruptured tendon).

interesting suture technique, the beginning and end. I presume that is to distribute/offset the strain?

I don’t know why, but this phrase just tickles me…

I agree…that is hilarious. If you overheard someone saying that, you would do a double take!

Yeah, just for a laceration, essentially just a whip stitch

Spinning mandrel. That’s how they do hoses. Once again, love the peek inside the sausage making. Thanks.

The day before we had “would you like to feel my colon?”

In a physical, I remember the physician snapping on the rubber glove and saying "This is not the favorite part of the examination… at least I hope not.

“let me know if you find my dignity in there anywhere.”

So had the inspiration from the artery project and the colon project, to try the spinning mandrel (thanks @marmak3261 for the actual name) for the colon. so I present to you:

The colonopsicle!

[edited as the video wasn’t working as an embed]