Glowholic…Glow junkie…something! ![]()

My PRU is located in my basement. It’s largely underground but has about 14" of exposed wall above ground. It’s poured concrete. It’s insulated so my heat in the winter does not leach into the earth. But that means the earth’s cool doesn’t leach into the basement during the summer. It’s not air conditioned but is dehumidified.

So it’s hot (85F outside) today. It’s 80F in the basement. But it’s 40% relative humidity so it’s pretty comfy.

My Glowforge PRU doesn’t want to play. There’s a temperature alert as soon as I turn it on. There’s an Amber button. This made me sad ![]()

But I’ve got other lasers. So a project I’m doing to help out another 'forger is gonna be done on another laser (shhh…don’t tell anyone I’ve returned to the dark side ![]() ).

).

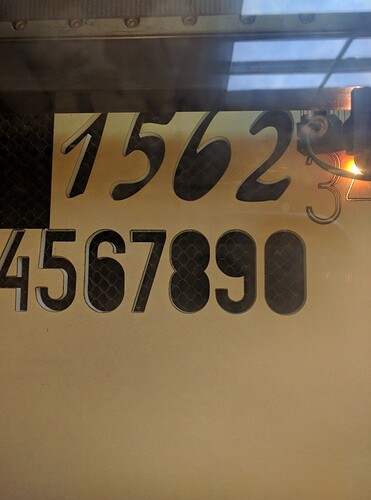

I’m cutting some numbers out. Just to show size and style in real life for him to use in a project of his own. Easy peasy.

But, first I save my Corel file to DXF (& PDF & AI as the laser can be finicky). Then I import it into the laser software. Now I don’t want to cut it all out of acrylic. One sample is going to be acrylic, the other set Baltic Birch. Both nominally 1/4".

Unlike the GFUI, I have to delete the objects I don’t want to cut instead of just telling it to ignore them. That means I’ll have to re-import the file again when I switch sets. And rest the focus (manually) since they’re not exactly the same thickness. First world problem I know. But irritating.

Good part is I can run a whole 24" piece in there so I can stripe the numbers across the bottom. (Dope slap - should have run them on the side so I can cut the end off and use the rest in the GF. ![]() )

)

Fire it up. My last calibration template tells me the setting. Doesn’t work. Pieces aren’t cut out ![]() Sheesh. Probably needs cleaning. Dial it back. Resend it to the laser. Doesn’t work.

Sheesh. Probably needs cleaning. Dial it back. Resend it to the laser. Doesn’t work. ![]() Beginning to get irritated. (Did I mention I had to set the focus by moving the bed & using a little stick? Or that I had to set the zero/zero for my project using a red dot laser attached to the head? Maybe I’m not starting to get irritated.)

Beginning to get irritated. (Did I mention I had to set the focus by moving the bed & using a little stick? Or that I had to set the zero/zero for my project using a red dot laser attached to the head? Maybe I’m not starting to get irritated.)

Dial it back. Resend the file. Run it again. Sigh. Eff it, I’ll just do a second pass. I shoulda cleaned it before I stopped using it when the PRU arrived. It’s probably just luck there aren’t any mice or spiders living in it.

The chiller is reading 23.9C so it should be fine but maybe it’s warm ![]()

Anyway, I get the set done and then the acrylic ones.

But seriously I feel so 20th century. How can anyone do good work with tools like this? I’ve seen the future and it’s way better.

Here’s the project. Just numbers for Pete’s sake.

I really need a forge fix.

A/C in the basement or hack a cooling air stream? Only need it until my Pro comes.

But man o man, this laser is a freaking dino.

As the guys from Tested said, if you’ve never used another laser you won’t appreciate how much better the GF is.

was my only shot at getting and using a laser. I’m not very handy, and I don’t want to mess around with something that’s really temperamental. As a designer, I already know how to use the tools to create the graphics, so give me a machine that doesn’t take a huge learning curve to operate or a ton of work to get things moving? YES! PLEASE! THANK YOU! I am one of those who (like you mention) will likely never be able to appreciate how incredible this machine is, but what little I have been able to guess at was more than enough to help me remain patient as I waited for it the past year and a half. Now, as an owner? I can tell you this machine has been everything I dreamed it would be and MORE!!! And I’m still only scratching the surface of what I can even do with it!

was my only shot at getting and using a laser. I’m not very handy, and I don’t want to mess around with something that’s really temperamental. As a designer, I already know how to use the tools to create the graphics, so give me a machine that doesn’t take a huge learning curve to operate or a ton of work to get things moving? YES! PLEASE! THANK YOU! I am one of those who (like you mention) will likely never be able to appreciate how incredible this machine is, but what little I have been able to guess at was more than enough to help me remain patient as I waited for it the past year and a half. Now, as an owner? I can tell you this machine has been everything I dreamed it would be and MORE!!! And I’m still only scratching the surface of what I can even do with it!

my own glowforge, easier to work with, plus the universal which will have a larger bed and a higher powered laser for the things i can’t do on GF.

my own glowforge, easier to work with, plus the universal which will have a larger bed and a higher powered laser for the things i can’t do on GF.