We just recently received a refurbished Glowforge after sending our unit back. But, we’re still having the same issues with this one that we did with the last one. Using Proofgrade materials, the laser refuses to cut using a Proofgrade Cut setting.

We’ve had to slow the cut down to 120 to get a solid cut out of things most times, and it still doesn’t cut through on some of our items. The board is laying completely flat. All mirrors and glass has been cleaned, but even at 120 speed (down from 155 proofgrade speed) it still doesn’t always cut all the way through (especially on smaller holes).

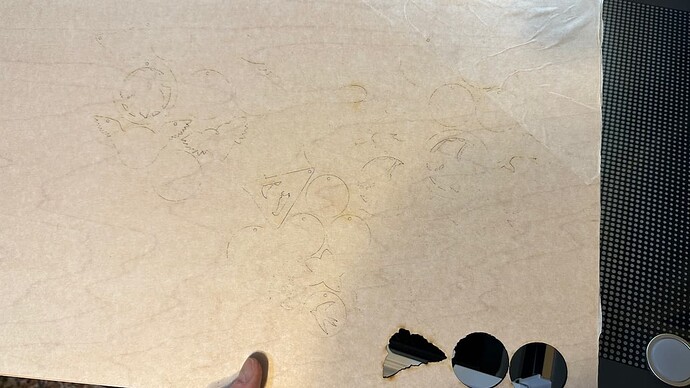

None of these items that we’re cutting are new designs. They all, at one point, cut just fine using proofgrade settings. And now, they won’t. As you can, hopefully, see on the photos, the engraving is fine, but every single piece on this (until we changed the speed lower) was stuck to the board, still. We peeled back the paper on the back just to make sure they weren’t just sticking to that, but they aren’t. They are really not cut out of the board yet.

This is really frustrating, as we sent our old laser in because of this issue, upgraded to the Plus, and still have the same exact issues we had before. Again, every one of these designs has cut flawlessly in the past, but now they won’t. It’s really maddening to print nearly an entire sheet and realize that nothing is usable. We’re a small business and we can’t afford to keep purchasing materials over and over because the machine isn’t cutting the way it’s supposed to.

If anyone has any suggestions, please let us know. We’re at our whits’ end trying to figure this out. Again, everything has been cleaned, this is a newly-refurbished machine, and the board and crumb tray are laying flat and in-place.