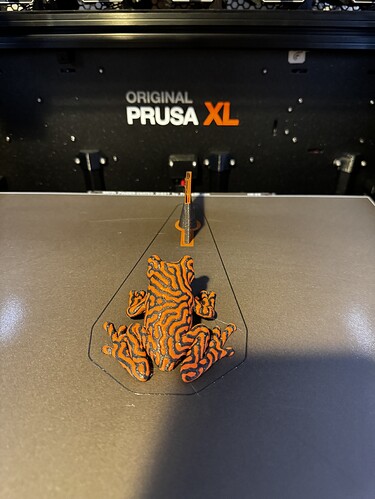

It was a 2 year wait, but the 5-headed beast is live! It’s not my first multi-extruder printer, but the tool changer changes everything (no pun intended) - you can see the tiny priming tower instead of the giant purge/wipe tower or poop chute like the bambu. It’s enormous (weighs almost 70lbs). Under the magnetic flexible print sheet is a place to lock in the machines steel calibration post which does automated offset calibration. Owning a CNC milling machine with a tool changer makes it slightly less novel, but it’s still cool. Tomorrow I hope to start my first multimaterial print (frog is all pla) with pla and Tpe to make a functional simulated knee joint (for teaching, where we can “damage” it to simulate different injuries for the students

One cool thing with the priming tower logic when mixing flexible tpu/Tpe it puts that in the middle with rigid on the outside to prevent oozing.

And for those wondering 36x36x36cm

Holy Wow!

Looking forward to even more great things from you in the weeks/months to come!

Oh, that looks like fun!!

That’s amazing. Can’t wait to see what all you create!

Awesome! They said mine is shipping next week. Fingers crossed!

I installed the new firmware on my Prusa Mini yesterday and enabled input shaping, and the speed boost is incredible. I’m really happy about the way they continue to support previous hardware.

It would be amazing to make cases of all the bone infirmities as well, I have a focus on MHE for some reason but there are many other cases from genetics to diet or disease and even just arthritis. It would make a great thing for a library.

That is a very cool spaghetti machine!

Prusa does it again…still love my mk3 but need some good reason to buy an XL…

OMG! What do those go for?

Less than the ![]() ! I would have expected more - though I imagine the material is the priciest part of a 3D printer.

! I would have expected more - though I imagine the material is the priciest part of a 3D printer.

The price goes up a bit when you add the extra tool heads and if you don’t want to spend all day putting it together.

I don’t print enough for the material cost to be very relevant. A 1kg spool of PLA is like $20-$30?

Swell recently i’ e been printing with the 75% tungsten PETG which is about $235/spool, but you aren’t printing big things in that (even with a hardened nozzle it beats up on the equipment. The prints weigh a ton (tungsten is 1.6x the density of lead) the key part is x-ray proof

Wow, that’s really cool! You always make the neatest stuff so I can’t wait to see what you come up with!

Dang, you are killing me on the Toy Count!

I would note I got the “fully assembled” (hint: not fully assembled, just “more” assembled than unassembled!) but it was well over an hour.

the one key design flaw in a quasi-industrial printer of this scale is the total uselessness of the filament path for printing flexibles. The extruder and hotend are great but there is no way I can see to actually feed a flexible filament since the block on the sides of the printer has a ball-bearing filament sensor that no flexible can push through, so the solution is to pull the PTFE tubing and run a separate tube to either a wall mounted or one of the side holders to the hot extruder itself. Which is ridiculous in a printer this expensive. Note once you get flexible to the actual extruder it works just fine…

It is big, although I will note the box was pretty amazingly built. And has really nice handles. Getting it up on my concrete dampener was quite the task (like the glowforge it is heavy, bulky, delicate and doesn’t like the be banged around…)