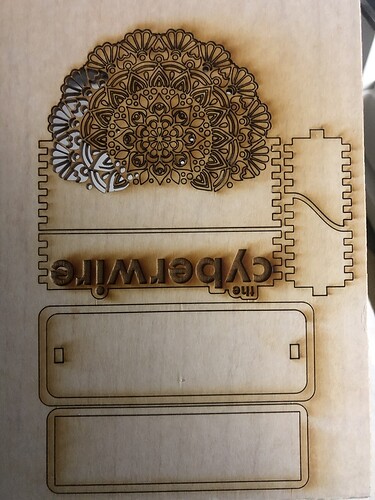

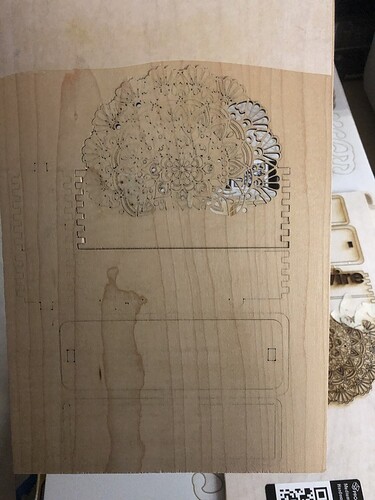

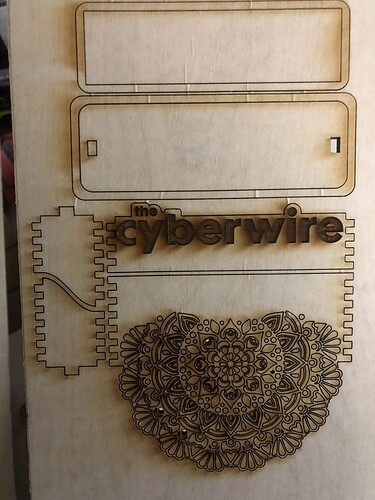

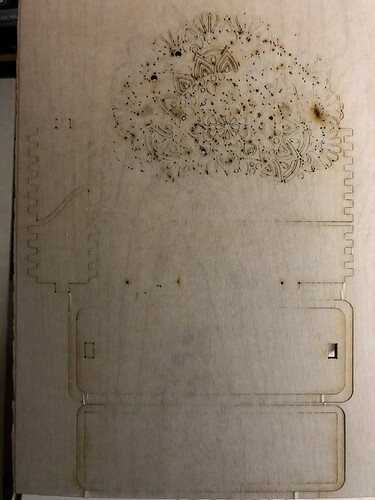

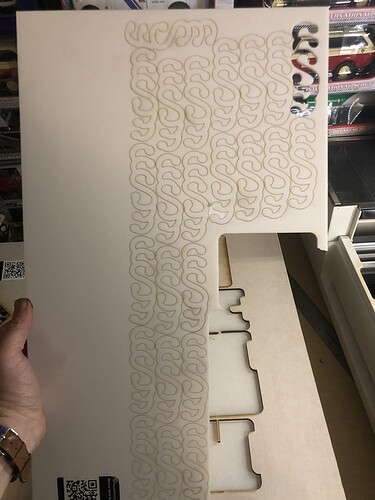

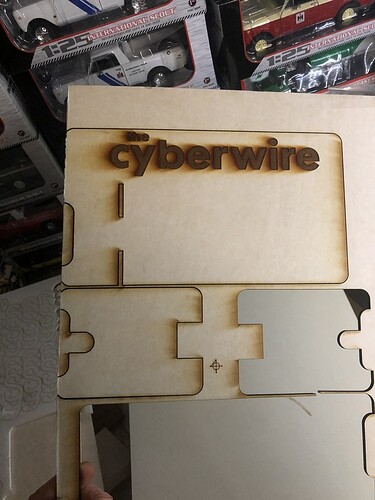

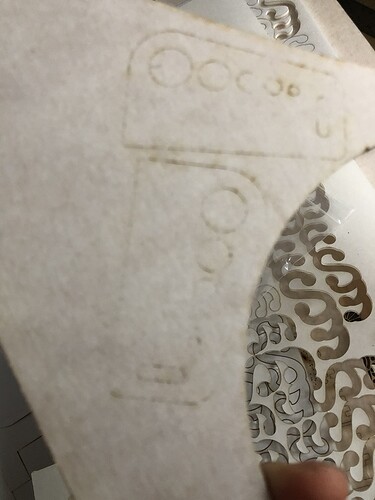

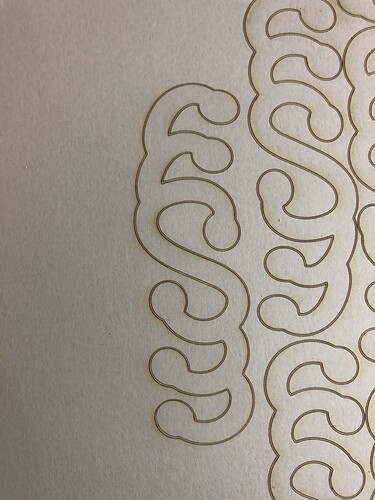

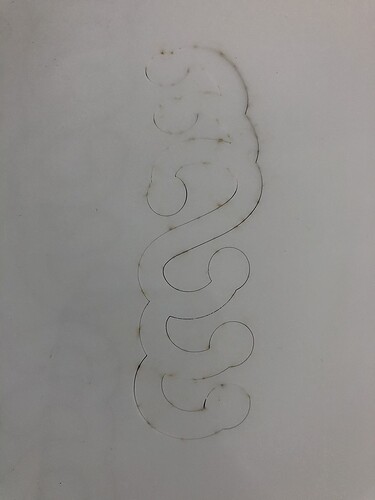

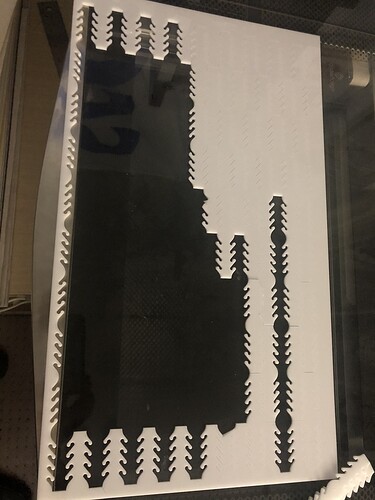

My Pro has not been cutting proofgrade material all the way through consistently. Sometimes it does and sometimes it doesn’t. I will attach pictures of draftboard, acrylic and maple hardwood, all with the same issue. This has been happening for a number of months. This evening, it failed to cut both the white acrylic and the gift of good measure on draftboard.

You might have three different problems going on there, which is what makes it so hard to diagnose these issues.

First thing to do is make sure the lenses and all windows have been cleaned. That can cause reduced power when junk builds up on the lens or windows. (All of them, including the hidden ones.)

Things That Need Wiping

With the draftboard cut…it almost made it all the way through…it might be slightly swollen from humidity. That happens a lot with draftboard…the stuff is like a sponge, and most of what I cut can be up to 0.134 to 0.146" thick instead of the normal 0.125" thickness that the default settings are set up for. You can check it by measuring it with a caliper, and if it is significantly thicker than 0.125" you can slow down the cutting speed by about 5 or 10 points to compensate. Should make it through in one pass.

Is that middle one a hardwood cut? I’d check the thickness of the wood there too…make sure the thickness is within spec…again that is close to cutting through, it might have just been slightly warped or if it is plywood, it can swell a little or have a hard spot in the veneer finish. The teeny tiny cuts part of the design actually cut better than the long smooth cuts, (which is surprising, that would normally be a harder cut) but it still looks like it might be a little thick. (Also can help to pin it down sometimes to make sure it’s extremely flat.)

For the acrylic, if cleaning the lenses doesn’t resolve the problem, it might be a function of the design. Sharp switchbacks in the laser movement can cause parts to not quite cut through.

Honestly though, since it’s happening across a wide span of materials, the first thing to check is the lenses and mirror. A quick wipe can restore the power.

I’m so sorry to hear that you’ve hit this snag, but I appreciate you providing all of these great photos.

I would like to check over just a few more things. Could you do the following for me?

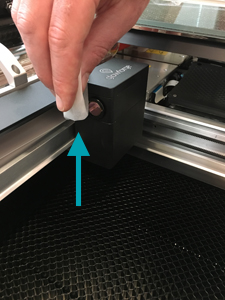

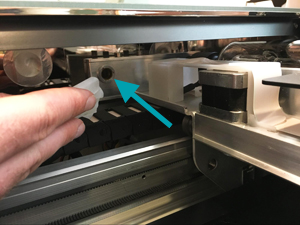

Please send photos of all your cleaned optical components, with special attention to any damage you might find:

- Both windows

- The printer head window, on the left hand side of the printer head

- The laser window on the inside left of the Glowforge

- The printer head window, on the left hand side of the printer head

- The printer head lens

- Both sides of the lens, top and bottom

- Both sides of the lens, top and bottom

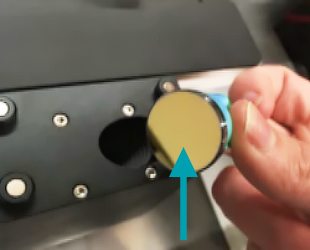

- The mirror inside the printer head

- The bottom of the printer head

Once we have those pictures, we’ll follow up with next steps.

Thanks @MarcM. I just need to look up how to access these parts, unless you have links handy.

Thanks also @Jules. The materials were all within spec when cut. I have found that if they aren’t stored flat, all the wood materials tend to warp, so I keep all materials stacked flat. I’ve also cut these same ear savers with no issues in clear acrylic (but have had the same issue with clear acrylic at other times as well). The white ones even had the speed slowed by 10 lower that spec for proofgrade. The others were at proofgrade settings.

just recording that I have the link.

The best section for finding these particular parts can be found here

I hope this information helps! We’ll follow up once we can review these images.

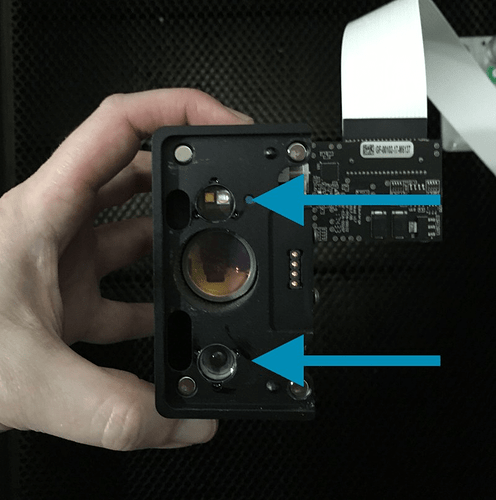

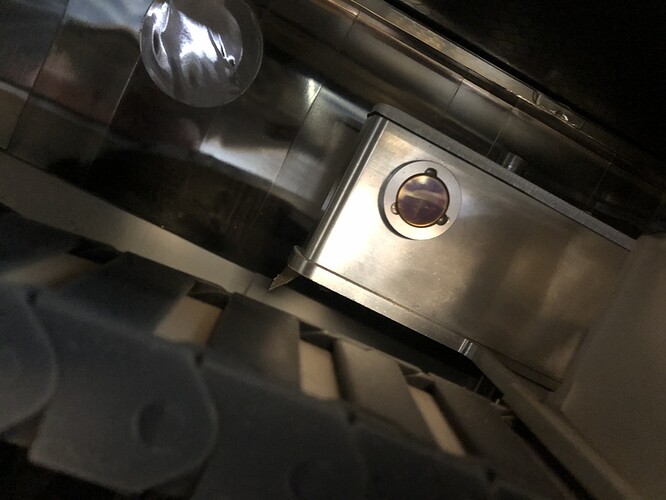

Attached are pictures after cleaning. All the parts were clean and no dirt came off on the cleaning cloth, except for the laser lens, which did have residue. It also has a bit of a corona around the edge of the lens, which you can see in the pic. This did did not wipe off and I did not try anything more aggressive than the lens wipe.

After cleaning, I have the same results. The Gift of Good Meaure did not cut all the way through. A bit better but not all the way. I then tried a few small pieces on acrylic and they cut okay, not a fully clean all-the-way-through cut, but they snapped out easily. Lastly I tried a sheet of ear savers. For this I slowed the speed down to 170 from the proofreads setting of 183 (and removed the paper from both sides). The straight cuts did fine, but the curved cuts were inconsistent. A few cut all the way through and came out easily. While others not at all. I was able to crack put about half of them, with several breaking along the way. Interestingly m, it seems that the cuts toward the front of the unit cut better than those towards the back. FWIW, it started cutting at the back.

Thank you for taking the time to send over these images. Based on the image of the Printer Head lens, I’m concerned that this blemish on your lens may be causing the behavior you are seeing in your prints.

I recommend that you purchase a new lens from our shop here

Once the lens has been replaced, please let me know if you run into the same behavior.

It’s been a little while since I’ve seen any replies on this thread so I’m going to close it. If you still need help with this please either start a new thread or email support@glowforge.com.