There are a few things you can do…

That can frequently happen due to natural variations in the thickness of the wood, (humidity causes the fill to swell as time goes on), or a slight warp/twist can develop in the wood. (That sheet is older, I can tell from the sticker.)

-

Always make sure the sheet is pinned down completely flat. (That eliminates warp problems.) I use the honeycomb pins for every cut…it’s just the first step of prep.

-

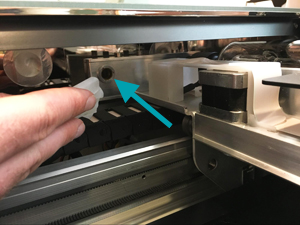

Buy one of these:

(Best $7 investment you can make for this machine. Use the pick to attempt to lift out the cuts after the first pass, and if they are still stuck, send a second pass of just the Cut. Set any Engraves to Ignore. Do not shift either the design on the screen, or move the material on the bed… It will line up exactly if you don’t move anything trying to match the screen shot. You can use a very high speed for the second cut, and it will finish the cut perfectly.)

Or you can double up some tape and try to lift the cuts out, but the tool is very handy, and you don’t wind up with tape all over the place.

-

For designs that have the potential to be problematic…like any designs that have tight angled direction changes (frog and lizard toes in the corners), understand that it might not cut perfectly with one pass at the default settings, and slow the cut speed down by about 5 or 10 points up front. That will probably cut all the way through in one pass. If it doesn’t, you can resend the cut after checking with the pick.

-

Or for tight cuts that you think might be a problem, you can set up for two passes in the Settings, and save a little time. I usually don’t because it’s not always necessary.

I tend to get the incomplete cuts in the front right quad too, but I think it’s caused by a slight twist along the long axis on the material…humidity does that here. I use the tricks listed above to keep from wasting time and material, which has frankly gotten too pricey to waste.

I’ve had my machine for five years now, and I still do these preparations for every print. Completely flat is critical, but sometimes you just have to account for Mother Nature too.

As far as cleaning after every cut…that might be overkill. Cleaning has the potential to damage the machine in a multitude of ways…smearing the lens and windows, wearing off the protective coatings, getting moisture somewhere it doesn’t belong, bending the wires and causing flex stress. You can run the machine for much longer than 40 burn hours before the lenses will need to be cleaned, and much longer than that before needing to blow out the fans. Not to say that it shouldn’t be done periodically, but cleaning the lens and windows is not the answer to every problem. (It’s just one of the most common for people who never clean the lens and windows.)

Anyway, try one or two of those tips…it might save you some material.