I’m cutting Mylar A 250 microns stencil material. the laser cuts fine in the middle of the crumb tray area but the right hand side doesn’t cut at all.

What can I do? I bought the machine to cut stencils specifically but I have not had any success yet.

If this is a new machine, it is possible that the optics were knocked out of alignment in shipping. Make sure that your optics are clean and then print the Gift of Good Meausure on Proofgrade material with Proofgrade settings on the right side of the bed. If it doesn’t print perfectly, send photos along with the date and time of the print to Glowforge support.

Hi yes it’s brand spanking new. checked the optics and cut the Gift of good measure and it didn’t cut it properly. the engraving is also fainter on the right hand side of the board.

I used the proofgrade medium basswood hardwood supplied. Have sent video and imaged to GF customer services and await the next stage. thaks for the reply.

Look on the left-hand side of the cutting head and see if you see anything unusual. Take a photo and post it here and send in an email to support.

It almost certainly indicates one of the mirrors inside the box on the left side of the gantry was knocked out of alignment during shipping.

Send a pic of the GOGM attempt along with the time of the print, support can check the logs but it most likely means the machine will have to be replaced.

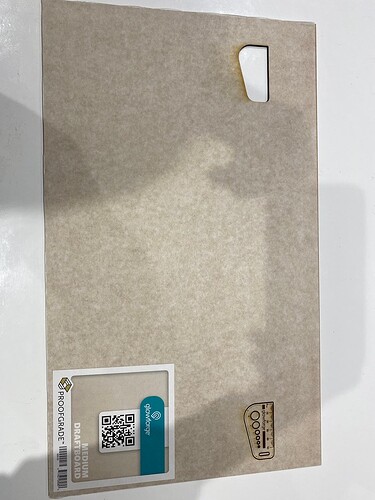

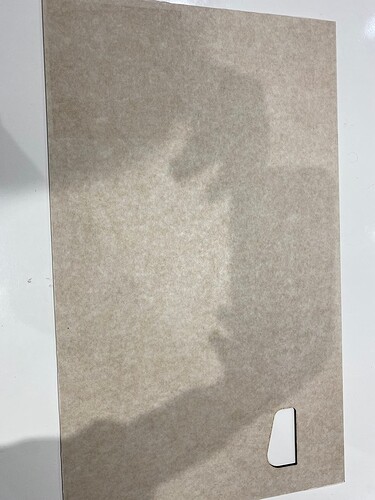

The test cut thrugh the left side of the driftboard but not the righ, not even a score on the back of the right one. Machine is level and I cleaned all optics.

here are the pics requested.

That tells me that the optics are not that far out of alignment that there are no marks that the laser will mark the head when it is on the right side of the machine. It is possible that the window under the left side of the gantry has managed to get a bit of crud on it, and that is blurring beam slightly. This does not matter much when the distance is small (when the head is on the left side of the machine) but as the distance gets larger the beam is more diffuse and there is not much power to do the job.

When the machine cuts well on the left and not so much on the right, that difference over distance is the only cause, and there are not many ways that can happen. As you are cutting there are curls of smoke wandering about and if the smoke is up against a window as the beam blasts it, it will leave some of that on the window. It can happen in an instant and the amount varies by how thick the smoke is against the window at that moment. Over multiple times the crud will get thicker. In rare cases it gets so thick it breaks that window, but the machine will be messing up before that happens usually and the window gets cleaned.

I have seen the window look fine by just looking but wiped with a zeiss wipe will leave a brown stain. The window under the left side and on the laser head will be the first to gather crud by a large factor so should be paid attention to.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.