Those were the days!

As you well know the “speed” of the engraving would be the power of the laser and the speed of the motors moving the gantry. neither of which has anything to do with the motherboard. all the motherboard would to it tell the gantry HURRY UP! ![]()

Deleted

What’s the barcode on a Basic or Plus?

Deleted

It’s a pro

Deleted

Um, yeah, I read that. That’s why I asked what the code was for a Basic or Plus. If they were all the same, then GF is using a single tube and changing how they drive it via software (pushing the power supply).

So that seems to indicate a different SKU and thus a different tube between the Basic and Pro. So much for simplicity in manufacturing a single tube (45W) and driving it differently through software. On one hand it’s surprising they’d go to the trouble of a different tube for the machines vs simply changing the power driving it (it’s a common technique in the cheaper laser market for tubes to be “rated” by using different power levels with the cheapest ones over-driving the tube to reach the rating they were looking for).

On the other hand, some of the engineering complexity of the rest of the machine would suggest that designing for manufacturability wasn’t necessarily a touchstone of their design decisioning process.

Nope. It scans to the same 0344799 - OVMBG as the other labels. Probably for different picking tools in the assembly process - some use the barcode and some the QR code.

Nice teardown pics!

I’d like to see the inside of the two mirror assembly. Your picture of the tube/mirror assembly also shows the shims under that aluminum housing for tuning alignment. That suggests alignment of the 2 mirrors are set at right angles in the assembly and elevation of that assembly one of maybe two remaining alignment adjustments.

There must be a way to pulse the laser to confirm alignment… ![]()

Nice share Jon ![]()

maybe one day i will rip apart the spare gantry I have…

![]()

I guess I’d be hesitant to touch that alignment between the tube and the mirror housing, but just taking the top off that assembly shouldn’t change anything…?

oh no I would do it to a SPARE I have (I took apart a basic for parts)

-J

That would have been one of the first things I’d have done. As an EE the circuit boards are interesting and all but not a whole lot useful I could do to them. On the other hand we have an idea of what the mirror assembly module looks like inside but have never seen a picture with that metal top removed. Are there adjustment screws for the two mirrors or is it all just epoxied together? If they are adjustable I think there might be a very slow and painful process for re-aligning the beam. Not as easy as other lasers but certainly faster and cheaper than an out of warranty return.

Deleted

Certainly makes user re-alignment far more difficult. There isn’t any easy way to fine tune the box position. When the screws are loosened to re-shim it’s likely the box will shift slightly up or down and even rotation is brute force. Guessing a person could take apart a old style distributer feeler gauge for different size shims.

Thanks for that teardown Jon! Great pictures.

I would like to understand that aluminum collar mechanism that caps the tube, wether there is an angle adjustment in it. The design looks overly complicated to just be a means of attachment.

I had suspected the mirrors in the assembly were fixed, without the adjustment screws to tilt the mirrors, and the number of screws visible suggest that fine adjustments are now incorporated in that collar.

Nothing leaves here as an assembly, and tearing stuff down to understand how/why stuff works is my idea of a puzzle to be solved! Since I’m not willing to eviscerate my glowforge (yet), I envy your position of having redundant parts to toy with. Thanks for sharing this. ![]()

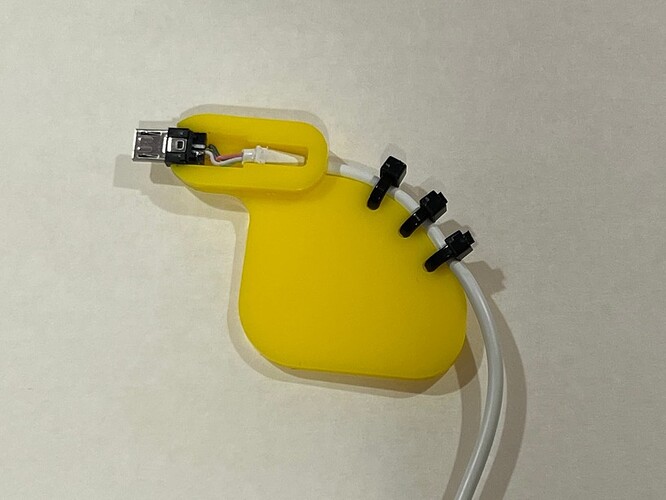

there are tiny holes in the metal rings, but nothing to turn, I was thinking it was some kind of pressure grip, but it looks to be glued… so I am not sure.

I’m not sure. Since those two mirrors are fixed, the design seems to eliminate the need to individually adjust the two mirrors to the single adjustment of elevating the assembly. I suspect if we fully understood the alignment procedure, it would be simpler than what has always been the standard method.

Of course, I have historically created problems for myself operating under the assumption that I understood a concept only to discover I was mistaken.

I notice a set screw in that first ring that suggests it clamps to the glass, and the second part is separated by threaded stand-offs implying adjustability… ![]()

The metal collar toward the tube with what looks to be the set screw in the side appears to be the “reference” surface for the next colar toward the 3 ringed casting.(the 19695 part) i would expect the shiny colar to the left of the set screw would adjust in such a way to bring the beam into “focus” before going into the redirect mirror housing. by perhaps mounting targets some place.

gotta run

Deleted