I am trying to cut 1/4" acrylic on my GF Pro. My settings are speed 125 and power is Full. It overheated after engraving on a 50 minute project. Engraving was most of that time and I engraved at a speed of 501 and full power with the “vary power” setting turned on. All of that seemed fine but once it got to cutting which was about 6-8 minutes left, it stopped with 4 minutes left. It cooled for about 2 hours then started again. It ran for about 2 minutes the stopped again to cool. After that it sat for 3 hours and still never started back up. This is a replacement refurb machine and I have less than 2 hours of work on it. Previously on the FB page I was asking about why I had so much smoke coming out of the machine. My compact filter had less than 5 hours on it and seems to be working fine. I can see it pulling smoke but it still continues to smoke out the sides and front of the lid. I have to the best of my ability cleaned everything (lenses and fans) but the smoke problem continues. Could these two problems be related?

Unfortunately, if your filter has gotten clogged, even partially, it’s not going to suck the hot smoke and air out of the machine fast enough, and that might contribute to overheating. You can try turning up the speed on the fan on the Compact Filter so that it evacuates the smoke more rapidly. (Might be getting close to needing a new filter too.)

If you did not move the material, you might be able to just send the Cut (ignoring the engraving) later. But if you shifted the material, you might want to start over.

Depending on what you were cutting, it can fill extremely fast.

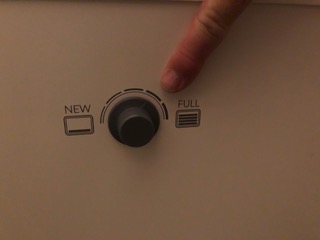

How can I tell if the filter is full?

It will stop drawing the smoke out of the unit when you have the fan speed dialed up. (If you’re seeing wisps of smoke coming out the front and top of the machine, you need to dial up the speed on the fan. When you still see it coming out when the fan is running on high speed, the filter is full or clogged, and needs to be replaced. You don’t want to see wisps of smoke exiting the machine.)

Thank you. I’ll get a new filter and see if these issues resolve.

Good luck with fixing the print too. You might have enough juice in it to finish cutting it.

Vent outside man. The cost of one filter replacement would pay for the modification. In my financial position I would find the $ of filter replacements prohibitive. That’s just me.

I agree. However the room that I have the Glow Forge is in is not ideal for venting out a window. Now I’m trying to consider all my options. Thanks for the advice.

If you own the structure it would likely cost less than a replacement filter to have a vent professionally installed through the wall. If you are renting that’s another thing.

When your Glowforge and Compact Filter are properly set up, you may have some harmless odor during printing which will rapidly dissipate. You may also smell something when you open the Glowforge lid after a print is complete. This is not harmful.

However, if you notice a strong, unpleasant or irritating odor when printing, or see smoke, shut off your Glowforge unit immediately. Smoke and fumes could be entering the room in excessive concentrations.

We’ve created a troubleshooting guide with illustrations. You can see it here: https://glowforge.com/support/topic/troubleshooting/print#excessive-smoke-or-fumes-during-print

If you’re still seeing or smelling excessive smoke or fumes when using Proofgrade materials, we’re here for you. Email us again and send us:

- The name of the material you’re using

- A description of where the smoke/fumes are coming from: the door, lid, or hose

- When you smell the fumes: during the print or after it has completed

- Photos of your Glowforge and your exhaust system

Also make sure the right side of your machine is not blocked–that’s the side fresh air is pulled into the machine, and if it’s blocked, or a piece of paper got drawn up on the right & underside, it can be blocking the air intake holes and thus the unit can’t vent or cool down properly (you can feel those if you can slip your fingers under the right central underside of the machine).

If there is not good airflow, that will impair cooling. But here is something else to think about…

Do you see any bubbles in your laser tube? I wonder if your pump might not be working correctly. If the coolant wasn’t moving well, it would take a lot longer to cool down.

I saw bubbles when I first turned it on the day I set it up. I do not see any bubbles anymore.

That’s exactly what you should see.

Thank you for the additional details. Have you had a chance to look over our last response? If you are still having issues with smoke please send us the requested information. Regarding your Glowforge pausing to cool, I extracted the logs from your Glowforge around the time of your report, and it looks like the unit was slightly too warm to print at the time.

Your Glowforge Pro features a closed-loop liquid cooling system that uses the air from the room to remove heat. It’s boosted by a solid-state thermoelectric cooler that allows for heavier use at higher ambient temperatures than the Basic. It is designed to be used when the temperature next to your Glowforge is between 60 degrees Fahrenheit (16 Celsius) and 81 degrees Fahrenheit (27 Celsius). To check, put a room thermometer next to the right hand side of the Glowforge; it draws in air from underneath, on the right.

You can try any of these things to improve warm-weather performance:

-

Try printing with no material on the bed (so as not to generate smoke and fumes) and no exhaust hose attached. If this works, then the problem may be that your exhaust hose is constricting the flow of air out of the unit, preventing cooling.

-

Examine the bottom-right side of your Glowforge, and ensure that there is no fabric or other flexible material underneath it, like a tablecloth. There are air intake vents, and if they become obstructed, it makes cooling less effective.

-

Try pointing a fan at the right side of your Glowforge. If there is warm air around the intake, this could help it cool off.

-

Power off your Glowforge when you are not using it. When your Glowforge sits idle, the fans are off, so heat can build up

-

Just wait. Your print may take a little longer when it’s warm, but your Glowforge will protect itself and make sure it cools enough to prevent any loss of power or damage. It’s clever enough to pick up from exactly where it left off, even if it needs to pause to cool down during the print!

-

Ensure that the sun isn’t shining on the lid. This could cause the inside of your Glowforge to heat up.

-

If you are venting outdoors, ensure that extreme temperatures or humidity do not enter the Glowforge unit through the exhaust hose. Disconnect the hose from the outside air when the Glowforge is not in use.

-

Turn your Glowforge off and open the lid for a few minutes before trying again. It’s possible for the air in your Glowforge to heat up, just like a car in the sun on a hot day, opening the lid will help that warm air to escape and your Glowforge to cool down.

If you are still running into trouble, please let us know the following so that we can investigate further:

-

A description of the things you tried and what happened

-

If possible, place a thermometer next to your Glowforge on the right hand side and measure the temperature there; if not, estimate the room temperature

-

The date and time (including time zone) when you had the problem

-

Take a picture of the exhaust hose behind your Glowforge that includes the part where it connects to your Glowforge, and the part where it exits the room

I look forward to your reply.

I can’t really say I’m having overheating issues as I am not currently using it because I did receive a message regards the smoke issue. I was told I should not use the machine and the GlowForge team would look to see what the resolution was for the smoke issue.

I’m still waiting on what for the smoke. This was the message I received.

@mactoddy, it sounds like we might have miscommunicated - I’m so sorry about that!

We were waiting to receive the information my colleague Josh C. requested before advising further on your exhaust. To save you just a bit of scrolling, here’s the info he wanted:

If you’re still seeing or smelling excessive smoke or fumes when using Proofgrade materials, we’re here for you. Email us again and send us:

- The name of the material you’re using

- A description of where the smoke/fumes are coming from: the door, lid, or hose

- When you smell the fumes: during the print or after it has completed

- Photos of your Glowforge and your exhaust system

I also see you mentioned picking up another filter cartridge - that would certainly rule out a clogged filter as a possible cause of your escaping smoke and overheating. That said, we’d love to take a peek at your exhaust system in the meantime in case your trouble is configuration related.

Thanks for your help!

Hi Gary,

I don’t meant to be snide or rude when I say this, but I did what you asked in your previous email and that’s when I was sent the email that said to stop using this machine. We are trying to launch a business with this machine and this is really becoming an issue. I agree that trying a new compact filter would help rule out possible problem but that is a $250 effort that may not be the problem. I’m wondering if you can look at the logs and see if you think the burn time would result in a clogged filter. We only ran the machine (what I think) was less than 5 hours before we had an issue and had get a replacement machine. From the moment the replacement machine showed up we had the smoke issue. That is why I don’t believe the problem is a clogged filter. All that being said, here again is the information you requested and a short video of the smoke coming out. Please let me know what else I should do.

Regards,

Todd

- The name of the material you’re using - Proofgrade Draft board - 1/8"

- A description of where the smoke/fumes are coming from: - Smoke is coming from both sides of the lid and the front and even thru the button hole.

- When you smell the fumes: During the print mostly

- Photos of your Glowforge and your exhaust system. See below

(Attachment IMG_0854.3gp is missing)

Five hours of actual use with draftboard would almost certainly clog the filter.

All your symptoms point to a clogged filter.