Actually, the place to go for help is on the Beta thread linked below…that’s so the engineers working on development will see it.

Be sure to go over there and repost it so they will know you are still having an issue.

To make the machine cut through, you will probably have to adjust your settings. If you haven’t figured out how to do that yet, you need to get comfortable with changing settings. It’s best to do that while NOT using the Passthrough though, so run a few tests on scraps of the material that you want to use in the passthrough. If that is Medium Basswood Plywood for instance, you will do this:

- Put a small sheet or scrap of Medium Basswood Plywood in the machine.

- Create a small design like a 1 inch square to cut. (You can use the Insert Shape tool in the toolbar at the top.)

- Make sure you have chosen Medium Basswood Plywood from the dropdown behind the Unknown button.

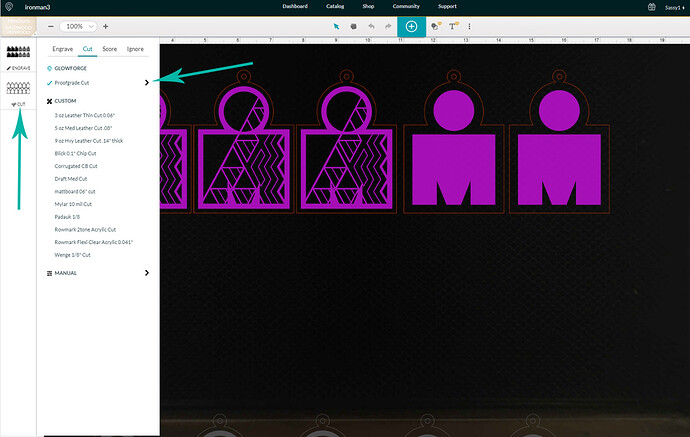

- Click on the CUT operation in the thumbnail column. Then click the Carat to the right of the Proofgrade Cut.

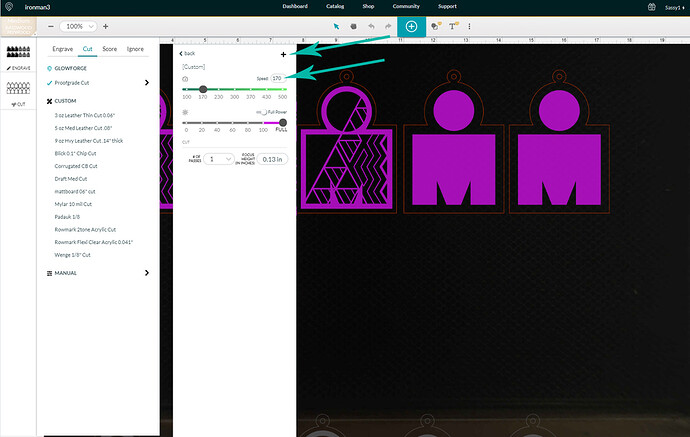

- The settings that pop out will be the default settings for that material. Lower the Speed Value shown by 5 to 10 points…no more.

-

Click outside of the box to close it, and Print the square. If you get a good clean cut all around, that will be the setting you want to use.

-

Open the settings again. Click on the little Plus sign above the Speed Value. (shown above)

-

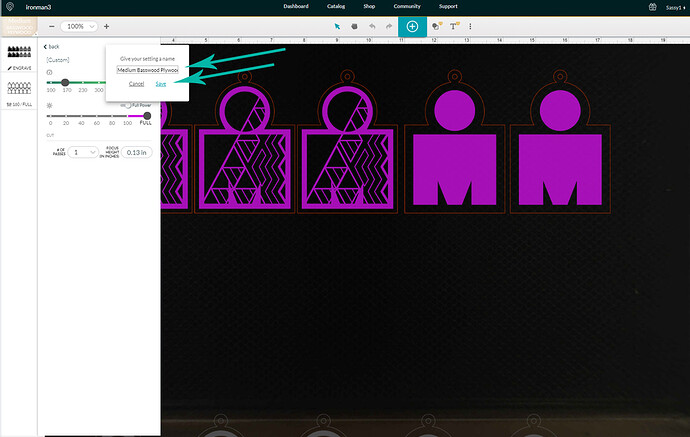

Give the Setting a Name and Save it.

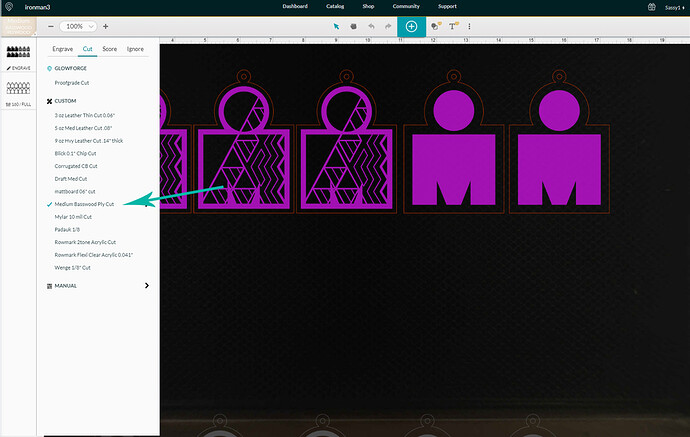

- When you run the Passthrough, you will click on this setting instead of the Proofgrade Setting to select it for use on the passthrough project. Just click on the thumbnail, then on that Custom Setting.

If you want more information on creating and saving your own settings, you can read about it here:

I’m going to copy this and put it over in the Beta thread as well, so other people who have the same questions might run across it.