Newbie here! We were cutting out some ornaments and had no problems with the PG Medium Draftboard. However we went to do the same print on PG Medium Basswood and it burnt a few of them and then we stopped.

Could it be the image settings? Not really sure. Speed was @150 and laser was full power. Previous to that I was using 0.234” thick plywood from Lowe’s which I was unable to cut through on 2 passes. I closed out the program and tried over on the Basswood without success. Struggling here. Any thoughts or suggestions appreciated!

Welcome to the forum.

When you use PG settings on PG materials you should get very reliable results. Can you share a photo of the failed print on the basswood along with a screenshot showing the settings?

One thing that you might not be aware of yet though, the settings for cutting through Basswood are going to be different than the settings for cutting through Draftboard.

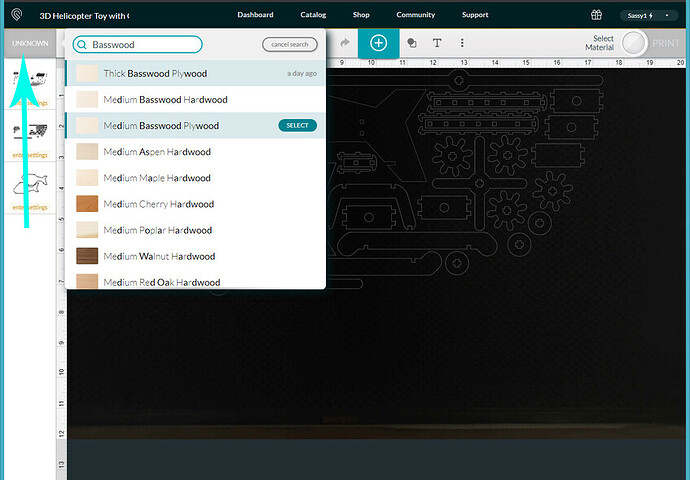

In order to load the correct settings for the different material, click on the button at the top of the thumbnail column and you can use the Search tool to just type in “Basswood”. Choose the correct plywood or hardwood thickness for whichever one you are working on…either Medium (1/8" thick) or Thick (1/4" thick) and it will load the correct settings for your model of machine.

Thank you for the reply! If I use non PG material. I enter the settings in custom, measure the thickness of the material. How do I know the speed or the number of passes it will take? Sorry for all the question

The best thing to do is jot down the settings for speed and power from a similar thickness PG material, then use that as a starting point. (If it’s plywood, use a similar plywood setting. For acrylic, use the correct acrylic settings for medium or thick material.)

Thickness of the material is critical in getting the right settings though, make sure you pay attention to how thick the material is that you are cutting.

Oh no,I’m sorry you’ve hit a snag!

Could you include photos of the print in question?

Additionally, I’d like to have you perform a standardized print for us to review. At your earliest convenience, please perform the following test print.

-

Print the Gift of Good Measure on Proofgrade material, using Proofgrade settings.

-

When the print finishes, leave the lid closed and wait until the fans stop and the picture updates.

-

If the Gift of Good Measure fails to cut through, take a photo of the front and back of the print and attach these photos to your reply.

Let us know how it goes!

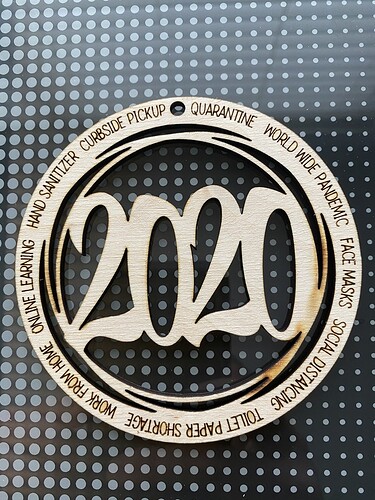

Hi Jules, I ended up getting som 1/8” thick Baltic Birch plywood. Used the “Medium Basswood Plywood Setting. I am getting burn marks. Any suggestions? Pic below

This isn’t really a post for Problems and Support, but did you mask your wood. That is the best way to minimize burn marks.

Yeah, @dklgood has the right suggestion…you can put masking on it before cutting (front and back) and it takes care of the streakies.

Be sure to use a credit card edge to rub it down well before using it in the machine.

Thank you for posting this print. The good news is that your Glowforge is likely performing as expected.

Our line of Proofgrade materials is protected with a removable protective white coating that you peel off when the print is complete. That will remove any stains left from smoke and fumes that are created from the laser printing.

Could you please let me know if you’ve had a chance to try the test print requested by Jeremy?

Additionally, I’d like to have you perform a standardized print for us to review. At your earliest convenience, please perform the following test print.

Print the Gift of Good Measure on Proofgrade material, using Proofgrade settings.

When the print finishes, leave the lid closed and wait until the fans stop and the picture updates.

If the Gift of Good Measure fails to cut through, take a photo of the front and back of the print and attach these photos to your reply.

It’s been a little while since I’ve seen any replies on this thread so I’m going to close it. If you still need help with this please either start a new thread or email support@glowforge.com.