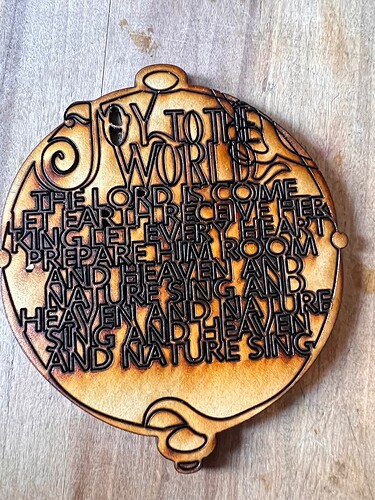

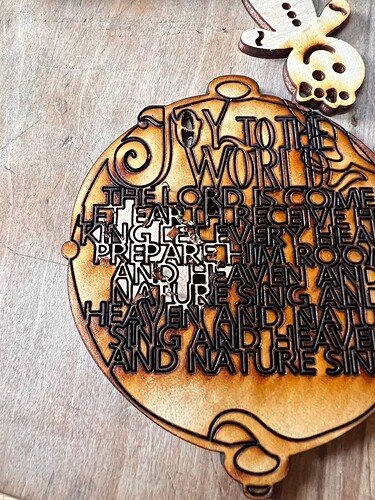

Using a GF design with PG settings & proof grade material. Bugger! Any ideas or anyone else had the same issue? Have a lovely day! Louis

Score setting is way too high, and it looks like masking was removed before printing.

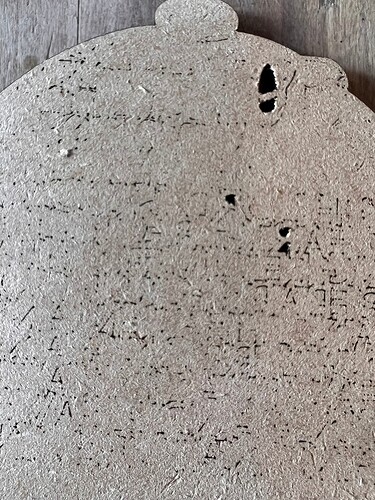

no, proof grade material masking still on. It is a GF design & should have cut through. You can see in 2nd pic that it hasn’t gone all the way through. Masking partially scraped below

No way that was designed to cut thru. The middle of every letter would be unsuspended. Do you have a link to the design?

Looks like a problem with your machine, when did you last clean the optics? How old is it?

That is a tough design to cut out and draftboard is an inexpensive but nasty material to cut it out of. Even with everything working perfectly the heavy smoke will get it dirty faster than any other material.

What is really nice about that design? There is no part that is dependent on the thickness of the material! Light plywood is thinner but with no MDF much easier to cut. It would look great in acrylic as well but you would have to watch it like a hawk that it did not start a fire.

Which leads to the real problem you are having. If cutting anything and you see a little candle flame the laser is not cutting as deep. If the window under the left side has even a little crud on it or the window on the left side of the cutting head, it will blur the laser beam and look like the cut you are showing. If you are not having an issue then they are clean and don’t need the attention, but cutting MDF will dirty up your lenses faster than anything else. This does not mean that the mirror and main lens do not need the attention but those two windows are more “out in the muck” more than the rest and being furthest away, any blurring has a greater effect than even on the main lens.

All that said blurring of those windows is not the only possible source of the problem. There is a fan on the back side of the carriage that blows air past the place being cut, and that plays a large part in suppressing that candle flame. If the airflow is broken up (by say a bed pin even) it is possible that could allow a very short term candle flame and the cut will not be as deep there. I have even seen where being near the front of the Glowforge gives the airstream enough backpressure to be a problem if the situation is marginal.

less than 12 months old

Thank you. The first cut was worse so I cleaned the lenses & I have a secondary fan in the exhaust tube. I am giving up for now. When I have more time I will fiddle! Thanks for your comprehensive answer, I really appreciate your time. Have a lovely evening!

I have a 190 cfm external exhaust fan that is insufficient alone but greatly improves the built in exhaust fan. There are some available that are up to 800 cfm! The less time that smoke hangs around in the machine the less time it has to settle on stuff and the less crud builds up, however a strong smooth laminar flow of air across the cutting area is the key,

At first I was using magnets to hold the material down and was far too late to discover that a magnetic field in the area the fan passed through severely slowed or stopped that carriage fan, giving me great expertise on how the airflow affected cutting ability.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.