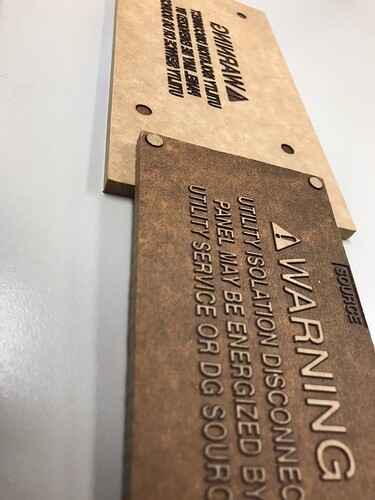

Made these emboss plates out of phenolic resin for a production run on .024 Aluminum. We did 500 impressions with no problems!

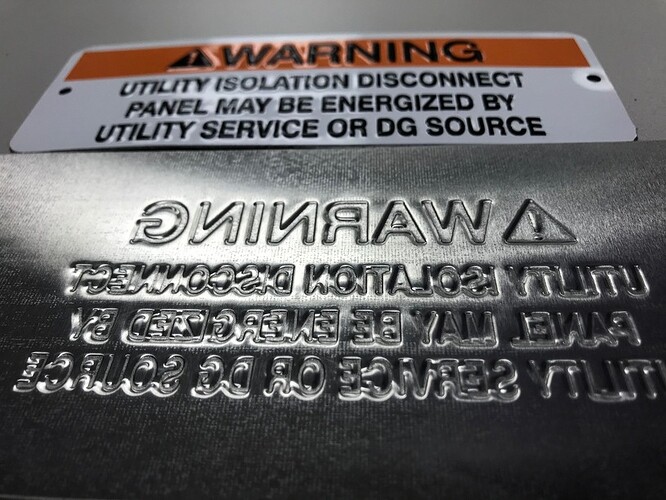

Well, that’s impressive! Do you have a photo showing what one of the aluminum end products looks like?

Very nice!

Wow!

Fantastic result! Thanks for sharing!

Very nice! I can see many possibilities for this.

fantastic! does the sign need to be embossed per code or is it just an aesthetic thing?

Amazing! Looks like something that would be fun to try. You just engrave the phenolic resin? Is it easy to find sources for?

Embossed to customer specification. We’ve run these for years but always had to order acid etched magnesium emboss plates. Very expensive! Now I can make them out of phenolic for pennies on the dollar.

Rainier Richlite Company out of Tacoma Washington. Their brand is called Richlite Natural fiber Composite. You can buy it in 4’x8’x .250". Those plates were run at:

Power: Full

Speed: 475

3 Pass

Wow! I have been thinking along those lines but was thinking a dense rubber rather than a reverse plate! How much did you allow making the inner plate smaller than the outer plate, so it embosses and does not try and cut?

What pressures do you use and how soft an aluminum? I have two sorts the one sold as flashing is very much softer than the other.

Hey thanks!

Those signs are 5" x 2.5" I left the male plate copy as is and offset the female paths .008".

Our aluminum manufacturer has this listed as “half hard” I’ll see if I can dig up the rockwell hardness on that.

Also we ran the plates on a 40 ton Thomson Clamshell Power press.

Wow! I was thinking of a hydraulic jack in a steel I beam frame for mine. Certainly not the volume of course but wondering just how strong I might need for it to be.

I was in the engineering department of a company that used them (or similar) for cutting out nylon life vests and they would cut a stack around an inch thick maybe 6 times a minute.

Im sure a homemade press like that would work just fine. The clamshell was overkill. Our smaller presses were tied up at the time.

Very cool results.

Thanks for sharing.

With the phenolic, seems there is some mixed information out there.

Is consensus that it is safe for cutting in the Glowforge? No concerns of laser damaging fumes?

Thanks

That is just really slick.

Thermal Decomposition of cross linked Phenolic polymers should be fine (have to be careful what they are mixed with, though it’s usually wood dust, paper or cotton). They are more likely to be sticky than anything else. Probably won’t smell great and might be messy (smoke might produce a varnish like coating). I’m sure @matt13 has better information on the outcome.