Inspired by images on Google Image search, especially this one, I decided to make my daughter a Platform 9¾ clock.

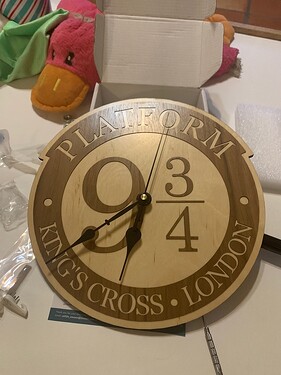

The 99% finished project:

And the SVG file (right click to save to your computer if interested):

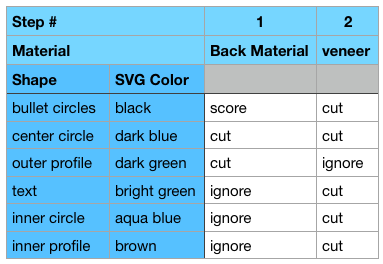

First step, I set the bullets at 9 o’clock and 3’oclock to score, and the clock movement hole and larger outline to cut to create the base of the clock, and trial fit it with the movement to ensure my hole was the right size (3/8" is the standard for the typical clock movements you find in craft shops, like this one from Michael’s):

Then I loaded up walnut veneer and used magnets to secure it directly to the honeycomb:

If I wasn’t cutting such a big thing I’d probably put magnets under too, because the honeycomb tends to burn through the backing on the veneer making it harder to weed and maybe reducing adhesion, too. But for such a large piece I was more focused on ensuring that it lay flat for the cut. I reordered the cuts so that the hole cut first, then the text, then the inner circle, then the outline, and set all other elements of the design to ‘ignore’.

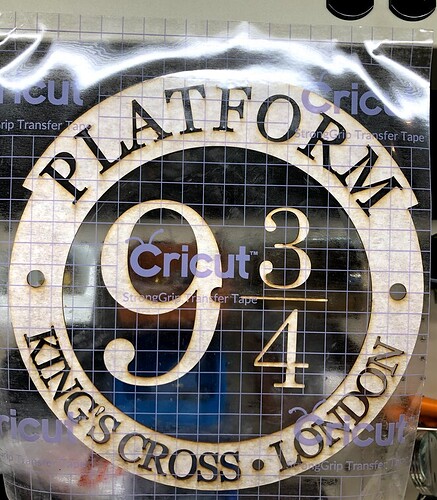

Then, I applied standard Cricut Strong transfer tape to the front of the veneer while it was still held in place by the magnets, pressing down to ensure that I would pick it all up as a unit:

Weeding was a bit more annoying than expected. Turns out, it’s easiest to hold the piece vertical so that the natural flex of the veneer works in your favour as you extract all the fiddly letters while ensuring their holes stay in place and well adhered. I had an old plastic spudger from some touchscreen replacement project lying around that worked well to get between the veneer and the transfer tape. Two views of the weeded product:

Then, using the score marks as a guide, I secured the veneer to the project:

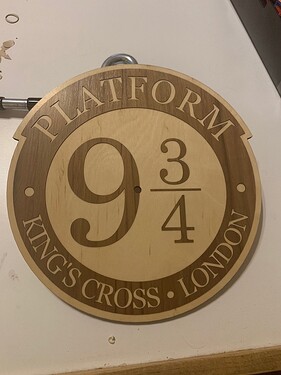

Unfortunately, while it looks OK at this angle, I only got the leftmost circle properly aligned, and the right side was off. Not by enough to matter, but by enough to make it look ugly when viewed straight on:

Even the aligned side is marred a bit by the black score line:

So I cut two plugs of maple veneer and inserted them. At a distance, or even when I asked my wife to inspect it, the defect is no longer noticeable:

The one remaining issue is that the clock movement is intended for much thicker clocks ( ¾" thick, amusingly enough) and I need to buy a new clock movement because I think the hands look silly so far from the surface of the clock. Overall pleased enough with the result.