Continuing the discussion from Ideas for stained "glass" windows:

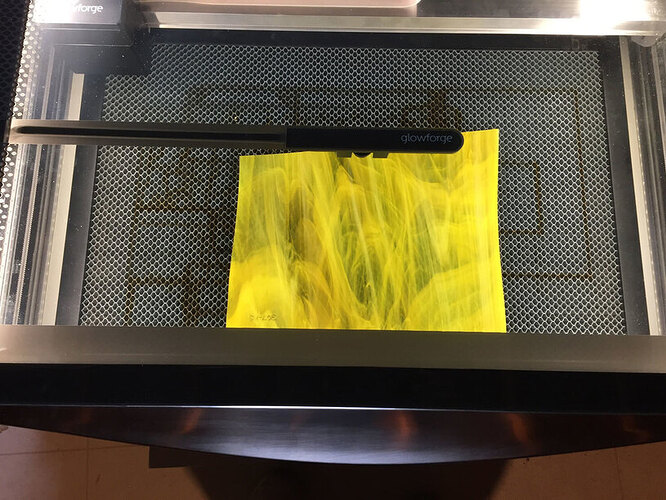

Okay, I did a little test today, in between working on a different project. Just to see if scoring stained glass for cutting is a possibility. I used some relatively smooth (i.e., easy to cut) yellow translucent glass and cut a flower petal design that was part of a design I previously cut for a mosaic brick.

For settings I used Cut, 100% power, 60 speed, focus height 0.116"

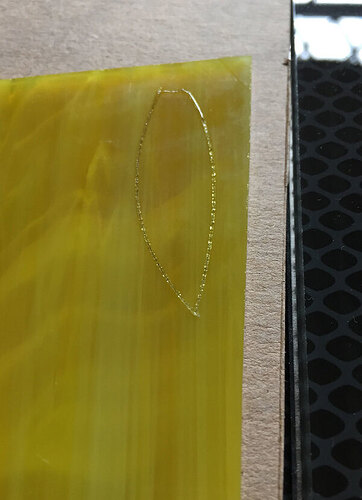

It definitely chowdered up the surface. Okay, I gathered up my two pair of glass breaking pliers (running pliers, and grozers), some safety glasses, and my normal glass scoring tool and took everything outside. Decided to cut that piece off the main piece of glass in case the breaking didn’t go too well (didn’t want to ruin the whole piece).

Then I used both pairs of pliers to break at the score lines. The problem being there was no running score to the edge of the glass like I would do with normal glass cutting, to relieve the pressure on either side of the line.

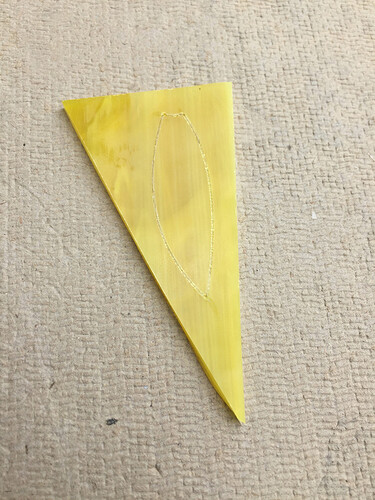

Surprisingly, it worked better than I expected:

It’s not a clean smooth cut in any direction, but if you are going to use a grinder anyway you can probably clean it up a lot. The tiny concave cut at the base of the petal was maybe not quite as good as the convex ones but that can be true with regular glass scoring/cutting as well.

One thing to keep in mind is that this was done on some of the easiest to cut glass; it would probably be more difficult on highly textured glass (which is also true for regular glass cutting). It’s possible that straight cuts (which are quite easy with a glass cutter) might be problematic; I didn’t test that. If you go this route you are still going to need pretty much all the regular glass cutting tools. Bottom line, for me it’s still quicker and gives better quality to use a glass scoring tool because I’ve already developed a minimum level of skill with it.