Got my first proof grade shipment today. Tossed a piece on to try and thought it was pretty cool that it perfectly fit it horizontally, right to the edges. Then the bed image came up and I was surprised to see the wood go out past the allowable area. Ok, I know that the tech specs state:

Cutting area: 11.5″ (290 mm) deep and 20″ (515 mm) wide

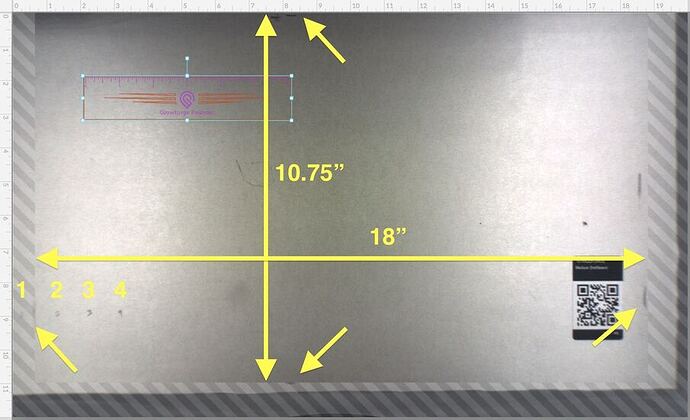

So I did some marking and measuring of what the available space is (see attached pics) and found that the area that I am allowed to print is 10.75" x 18". Is this expected behavior?

If I leave the board flat and only use the available space, I loose 1.4" of material on the left and 1" on the right. If I move the board one way or the other, it is now at an angle, being up on the lip of the honeycomb and edge of the tray. I understand that is not good for accuracy if I am using the whole board.

My primary use for this is to cut out entire sheets of items at the same time, so I can’t set it on the lip and have the angle and only print part of it to be able to use the edge. So am I just out of luck on that outer edge of material?

On the lip or not, available area not being as advertised reduces the number of items I can cut at a time. I had planned to put 15 into the 20x11.5 going right to the edge of that space, and now can only put 6 into the 18x10.75. That is a HUGE reduction in volume for me.

Am I hosed or is there hope?

Gonna have to trust the measurements. I had 3 more images to attach showing how I got the values, but I am only allowed 1 picture as a new user apparently.