Another data point for troubleshooting- I think this is going to be my last for a while. I printed out the risers that are the same height as the crumb tray, found here: Risers to Make Lasering Thick Materials EASY

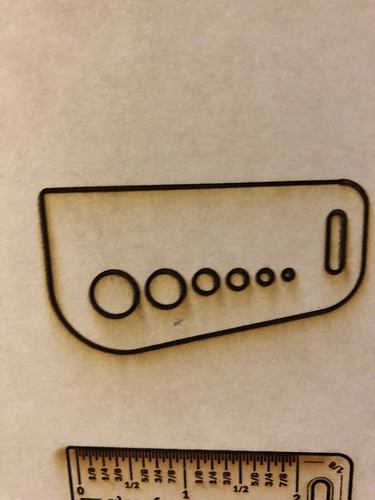

I set my PG Draftboard on top, and it seemed to fit nice and flat. Unfortunately, it did not cut through after 2 passes.

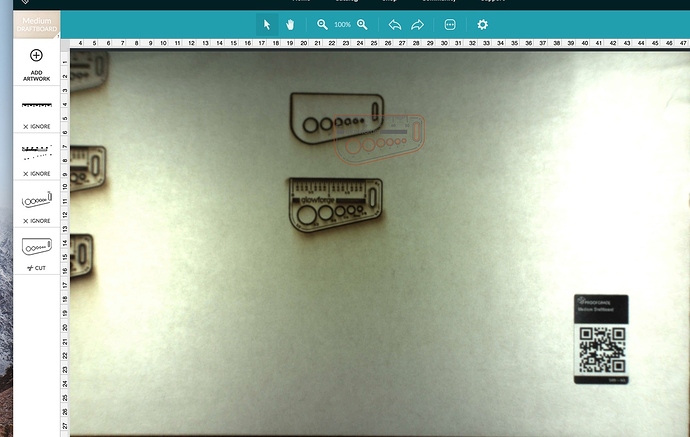

I also noticed, with or without the crumb tray, it isn’t detecting that I’m using PG materials, and the camera doesn’t seem to be in focus. I even tried adjusting the material height manually a few times (+/- 2 mm in either direction) and it didn’t help.

Here is what my GF looks like when I have the PG Medium Draftboard in. (Crumb Tray, or 3d printed risers):