So I only had a 15" inch straight edge in my tool bag and used it to probe the flatness of the crumb tray. There does seem to be a slight bowl shape towards the center of the crumb tray but how does that account for my inability to cut the material along the right side?

If your material dips then the focus it gets when it scans the center will be different. If it doesn’t dip then you really don’t have flat material (flat being relative to the bed). If you tap the material in the center it should sound hollow.

If it scans the bed when calibrating without any material on it then the calibration will be lower (it takes the measurement from the center) than it really is over most of the bed.

That would make sense on smaller pieces of material when calibrating but I used Medium Draft board and Medium Walnut ply both of which are 20" inches wide and sit on the entire crumb tray. Both materials are rigid and I would agree that they may have a warp even if I am only securing them with magnets from the left and right edges. Taking that into consideration, the wood becomes a bridge over the slight (1/32" ~ 1/16") bowl in the middle of the crumb tray, and if what you say is correct why would I only be able to cut the left side and not the right if the calibration took place in the center of the material?

I would agree that the focus is going wrong somewhere but where and why are the questions. I am also partial to thinking the full laser power is not being fully delivered to the laser head the further it gets from the secondary mirror on the left (Maybe)?.

I will continue to test checking the flatness of the material but it sucks that I have to do this wasting material to find the issue.

That’s the question! Is the left side not as high as the right side?

This would be a great issue for Support to weigh in on. ![]()

That would happen if the mirrors are out of alignment. If this was any other laser you could put paper in front of the mirror and do a test pulse and see if the hole is in the middle.

So I did more testing tonight and I definitely need GF Support to look into this.

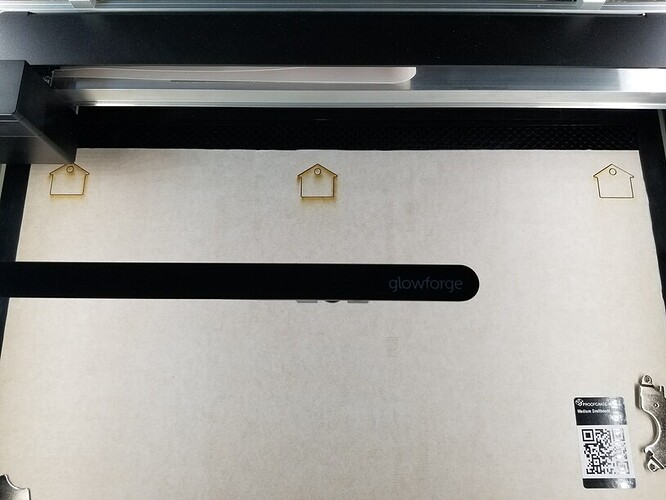

I made three cuts in one go. One on the left, one in the middle and one on the right and I continue to have issues along the right side not cutting all the way through. Photos for the records:

All three cuts:

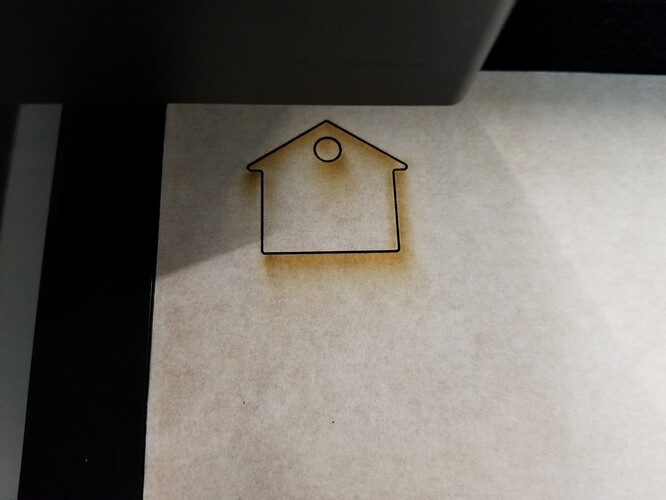

Left Cut:

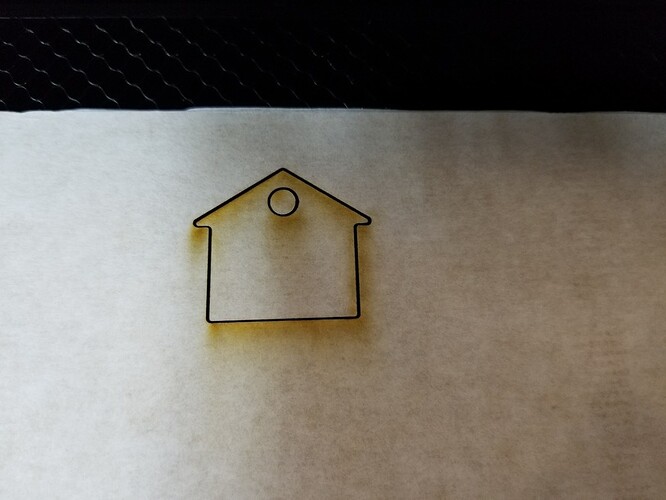

Middle Cut:

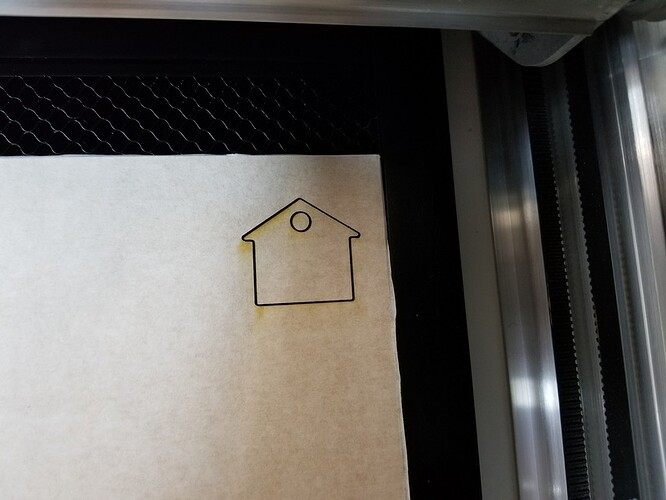

Right Cut:

Final Results:

The last image represents what was cut all the way through. The right cut is not going through. I made sure everything was level as noted in my previous posts. Notice the right cut image has barely any scorch marks when compared to the other two. This could mean nothing or maybe it does?

I’m so sorry for the delay in my response. You’ve done a lot of troubleshooting work for us, so thank you!

I’m looking into it. Thanks for your patience.

Thank you @jaz Let me know if I need to power up my forge.

Edit : its on if you need to take a look.

@jaz I never heard back from you tonight so I’m going to shut off the forge for today. Please let me know tomorrow what I need to do. I have a large project that is on hold and I really need a resolution to this issue. Again, I greatly appreciate your time on this matter.

I just want to double check - when you cleaned your lenses, did you clean everything listed here?

If not, please follow the directions to clean all of your lenses and windows.

If you have cleaned everything, please let me know and we’ll move on to the next steps.

Thank you so much.

@jaz No, I only cleaned the Head Window and the Laser window. I’m currently cutting a project now. Once it is complete I will take the head apart and clean the internal lens as you have outlined in that link. I’ll report back once complete.

@jaz ok. I cleaned all lenses as instructed in that how to guide you provided and proceeded to do a test cut along the right side of my material. I am still running into the same issue. The laser is not cutting all the way through on any design along the right side of my material (This time Medium Maple Plywood). I have been using the forge all day today but I am restricted to only cutting along the left side.

Whats next?

Thank you so much for trying that.

I’m very sorry, but I think we should replace this unit. I’ll be in touch via email to sort out the details.

I apologize for the inconvenience.