Hi everyone, this is masked leather using the following settings:

Material Setting: Thick Natural Leather

Endurance Builders: Engrave: 1000/75/270/1

EST YEAR: Engrave: Default Settings

Texas: Score: 300/23/2

Outer Outline: Engrave: 1000/75/270

Inner Outline: Score: 300/25/2

Shape: Cut: 168/100/3 (5oz leather takes 2-3 passes)

Several years of experience cutting this material, so it’s not new material to me. I run my machines for several hours a day almost non stop and so this occurred approximately after 3 hours of continuous running.

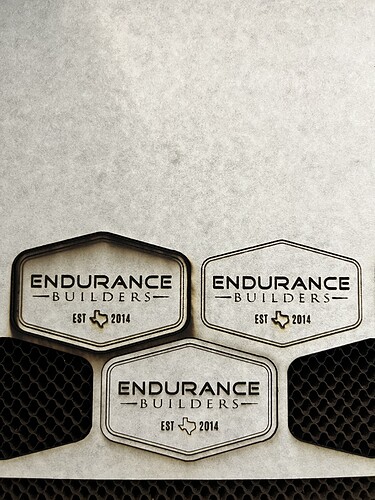

I’m cutting a few hundred of these and after about 3 hours of runtime on a GF pro, I experience what you see on top row. The laser gives unexpected results, I get extremely heavy scorching and a much thicker cut line that actually doesn’t come close to cutting through the material. The other patches all have very clean cut lines, and cut through with ease. You can see where I stopped the machine on the 4th patch, notice how thick that cut line is?

I have several years of experience running this machine so airflow is clear from under the right side, inside, and exiting into the filter. I cut a lot of leather so I deep clean the machine every other week and I’m running with a new Carriage Plate (replaced a few weeks ago) and a new Hose.

Any thoughts? This machine is 4 years old, I have a second machine so I’m not down but I’d like to try and troubleshoot this.

I’m going to send it to support but I thought it would be good to capture here in case someone else has experienced this and has some insight.

Thanks in advance.

1 Like

There are a few inconsistencies in the bottom row right corner as well as the top row furthest right, but it goes completely wrong where you indicate. If you swap the printhead with your other machine does the same thing happen? Have you considered cleaning the optics more frequently? Any debris on the lens could cause the focus issue.

2 Likes

I have not tried that, good suggestion. The 2 on the right are just shadows, the tape is moved on that side a bit. Optics were fully cleaned 24 hours ago but will have a look to see if they got dirty again.

1 Like

That happens to me when the leather is thicker or thinner - so it ends up out of focus. That can either be the leather physically being thicker, or something getting under there. It’s also possible that you’ve got some debris/dust in the focus tube of your lens so it’s getting caught up…pull the lens and mirror out and run a baby wipe through the tube?

3 Likes

Cleaned all of the optics and first print came out as expected. I didn’t see anything obvious during the cleanup so I’ll run it for a few hours and see if I can replicate the issue.

4 Likes

There it is! After 2 hours of cutting I ran into the issue again on the cut. You can see it puts out a pretty decent flame. I stopped it after 1 pass to prevent a flame up on the material. Now I’ll recheck the optics.

2 Likes

That seriously looks like a blockage in the chute under the air assist fan (the medium size one at the back of the carriage plate)

4 Likes

That would be my guess too. too much “funk” accumulating in the long run. and yes folks funk is a technical term.

7 Likes

What happened after you checked the optics?

1 Like

I’ll check that, it’s a new Carriage (replaced 2 weeks ago).

1 Like

Could it be clean but the fan isn’t working?

5 Likes

Not sure how to verify a local hardware component failure but I can swap the fan and see if I get improved results. It would be great if these things had an SNMP port or someway to get component level monitoring of the various devices in the machine.

2 Likes

Removed, cleaned (there was a bit of the sticky funk) and swapped out the fan. Thus far, first few prints are excellent. Looking to check again after 3 hours of printing. Thanks for the feedback!

I think sometimes I forget I can hit 20 hours of printing in a couple of days, so if I wait 2-weeks to clean this piece it may present a problem.

4 Likes

I ran clean for several hours today until now. I submitted a ticket so I’ll see what support suggests. Definitely have been able to recreate the issue after 2-3 hours of near continuous job prints.

3 Likes

How long after this happens can you start another run and get good results for 2 hours?

1 Like

I haven’t specifically measured that time. Getting ready to try a Print now, it’s been a couple of hours.

If I haven’t mentioned it already, having an Anesok Endoscope Camera Cable comes in really handy to get a visual around the inside of the machine without taking the machine apart. It’s lighted and plugs into your smart phone and you can probe around the machine and take photos.

https://www.google.com/search?q=anesok+endoscope+camera+cable

2 Likes

So, after the 2 hour break, I got a nice clean Print.

Also, I noted when it’s going to occur. The laser gets much brighter and has more of a splash to it when it hits the material on an engrave if that makes sense vs. the straight thin action. Then during the cut, for sure gonna get a big flame.

3 Likes

Made contact with Support on this and the Logs indicate a potential issue with the focus mechanism intermittently failing.

So, gathering up photos per this help article and sending those back for next steps.

https://support.glowforge.com/hc/en-us/articles/1260801319449-Troubleshoot-Printer-Head-Connection

4 Likes

Glad you’ve made contact. Hopefully it’s an easy fix with a new head and they can get you back on track!

1 Like