What about the acrylic tiny “bricks” not dissolving? Shouldn’t a tiny 1/8 by 1/4 by 1/2 inch thing show some dissolve-ness in an ounce of acrylic? (Like 1 part acrylic to 20-25 parts acetone) in 25 minutes? do i have a bad can or am i expecting too much?

I had left my initial dissolve over the weekend, so couldn’t say how long exactly it takes. 25 minutes does seem a bit fast for dissolving though. It should be really tacky if you try pulling it out after that long though.

If thays the case, does it need to have a lot of dissolved acrylic in it to get it to bond two pieces of acrylic? I had tried to bond two bricks of those dimensions together also, first by dripping between the two and then pouring on top of them. It seemed like the acetone evaporated before it bonded… but this was pretty much almost straight acetone. Should that have happened?

Gas water heater, right?

Duh! They dry faster that way!

You do not have to dissolve ANY acrylic into the acetone for this to work.

If you have good contact between the two pieces then you probably don’t even want to since the thinner the acetone is the better it will wick into the join.

If they don’t fit quite right then adding some acrylic will make the “glue” thick enough to stay in place without running out, and will help fill any gaps. The actual join is based on dissolving a little bit of both sides and allowing them to meld together before the solvent evaporates.

Leave the acrylic in the acetone for long enough to dissolve. If it take an hour great, if it takes a day then wait a day. Quality cannot be rushed.

Try this.

Take two small pieces of acrylic. Pour a small amount of acetone into a shallow dish of some kind. You only want enough to cover the bottom a little bit. Set both pieces in there, and cover it with something to retard evaporation. Wait 5 minutes. Take the pieces out and squish them together hard (best to clamp them if you can). Wait 30 minutes and unclamp.

My thing is clocks. I intend to cut plates and wheels out of Rowmark engraving acrylic with a realistic looking brass surface. I glued two pieces back to back as a trial. My local super helpful Multicraft plastic supplier suggested a slower drying slightly viscous cement that comes in a tube. This worked well. It may be exactly what you describe by dissolving acrylic in acetone.

Most of the commercial acrylic glues use Methylene Chloride instead of acetone as a solvent. It works better/faster but is MUCH more toxic. Acetone is actually quite safe (from a toxicity standpoint) as far as solvents go. Don’t go tossing the rags next to a gas water heater though.

I got me some weldon, and some acetone. The weld on does have some of that methyl chloride as a partial component. An experienced vendor for 20 years of acrylic sheet uses straight methyl chloride and has gotten used to it over the years, so claims it doesn’t affect him much. I was a bit worried about opening up the weld on 4, but after we did open it, it seems a lot milder than other chemicals ive whiffed growing up (stepdad was a commercial painter), so between oilbased paint and stains, and paint thinners and all that good stuff, i feel MUCH much safer handling acetone and weldon.

Just got some acrylic cement, Weld-on brand. With all the previous posts, I was expecting the worst…

The smell is almost non existent…

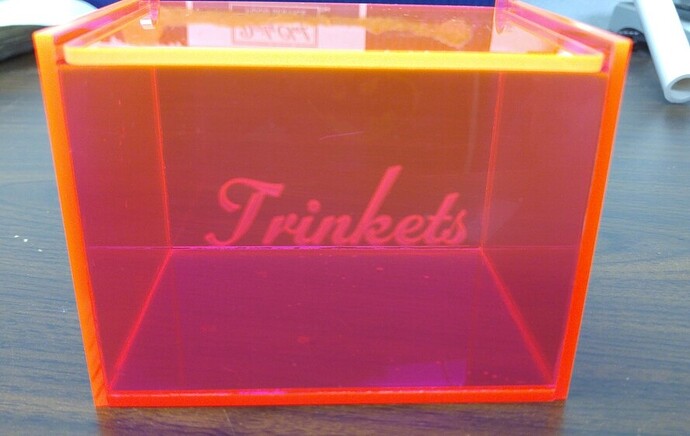

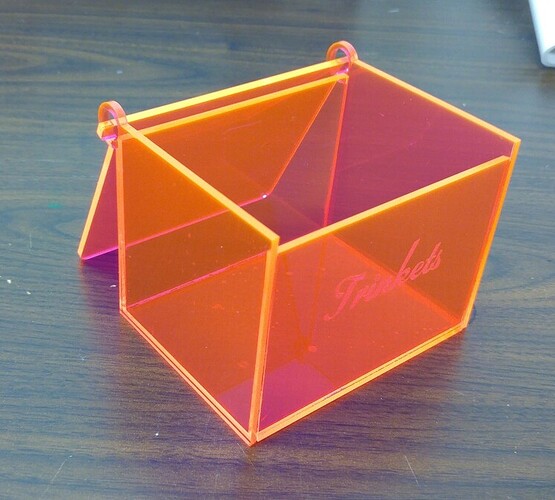

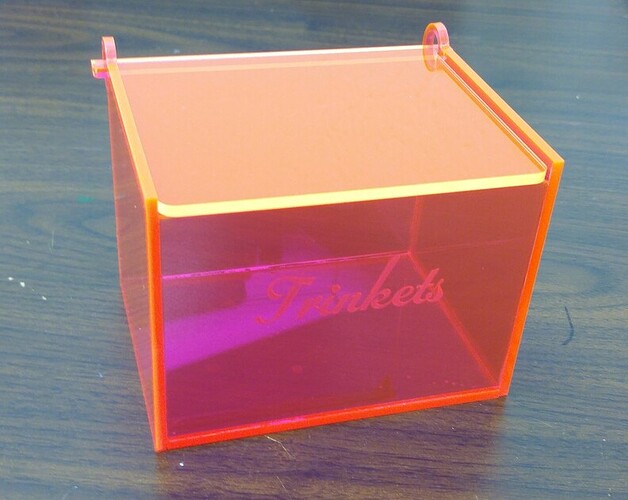

Made a quick trinket box to try out the ease of use.

Used very little along the joints and it worked like a charm…very fast.

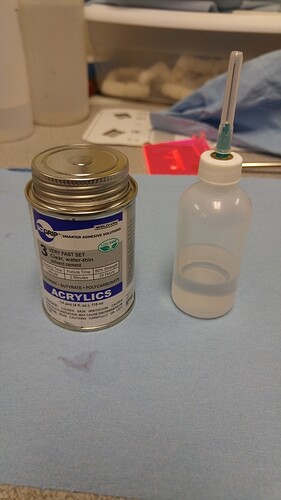

The only issue was that my applicator bottle may have a needle that is a bit large since the liquid dripped out a bit fast without squeezing the bottle at all.

Nice!

That’s the solvent I used to construct a saltwater drip filter from acrylic. Easy to work with. be sure to cap it tightly!

Interesting… I may have to give the actual solvent a try to get a fair comparison.

To prevent the dripping, you hold it needle pointed up and pre-squeeze, then relax ever so slightly. That gets you some negative pressure to prevent pre-drip and to prevent post-drip as well.

Oh totally, I was worried too with the warning label and all that about taking in a whiff. I used to spend a few summers with my stepdad’s painting crew, painting houses and apartment buildings. I’ve taken in WAY more potent smelling stuff than the weldon/sci-grip stuff. I tried the acetone thing like was suggested and i may try that again when i’m out of formula 4, but where I’m dealing with so many pieces and i need a quick strong bond, i have to give it up to formula 4.

Do we still call it weld on? Or start calling it sci grip now? In a little letter from the supplier that came with the amazon package it explained scigrip bought out weldon?

IDK I just call it acrylic cement…lol

I plan on trying Weld-on, too…so your report is valuable.

This sounds like a case of sinusitis…![]()

It’s reslly all in the wrist. Most of the time you could do as jacob says, but with a fast, steady hand (and a thin gauge needle), I find plenty of times where I let it drip out as I move the needle along an edge, as it gives just the right amount of equally dispersed flow. Try to practice up to this.

Another protip: when taking flat objects and putting them together, run the syringe bottle along the interior seam whenever possible. This helps any extra that wells up against side 1 and side 2 fall into the joint.

Sometimes your needle will get clogged, especially if you squeeze a lot (because if there’s an air pressure vacuum (that keeps it from dripping), and you let go against an edge, you can pull up a tiny amount of melted acrylic that will re- set itself in the needle. When this happens, take the cap off. (Important part) and move away from the bulk of the rest of the weldon. Run a cigarette lighter over the tip of the needle.

Thank you so much!

I know it feels a bit wierd to me too. I started this thread completely inexperienced with no previous information to base understanding on… now having got the stuff (by the quart) and spending DAYS molding HUNDREDS of flats together at the edges, I feel plenty accomplished and have gained a mountain of understanding.

It is thanks to you guys and a mentor i met recently who has been doing acrylics for about 20 years. Being able to see firsthand running a bead down some long edges, gave additional perspective. The needle unclogging thing came from him, ive only had to do it twice.

And I can’t stress enough how thankful I am for hand-eye coordination and patience tempered by many years of thoughtful video gaming.

Looks like an 18ga needle (green) where a 20a (pink) or 22ga (cyan) might be a better choice. If you have a friend who is a nurse/doc I am sure they can snag one for you.

So these are the same type of needles used for giving shots??! That just creeped me out…lol:anguished: