I have never made a box like that, but it reminds me of the dodecahedron I made for my daughter, where I made similar “connectors” to your corner pieces instead of the usual 3d-printed pieces that require screws. I cut several test pieces to get the spacing/sizing just right, so the intersections had the precise gap I wanted when assembled.

I didn’t highlight the connectors in the thread but if you zoom in on some of the pics you should get the idea. I think very similar, in that they fit snugly into slots in each panel…

For me, it was worth the effort and a little waste material.

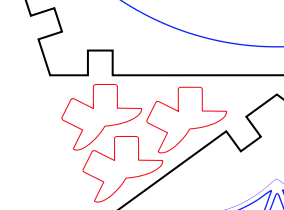

Here’s the idea. The square tabs slot into the notches on the panels, and the little wings just make them the perfect fit to the thickness of material I used.