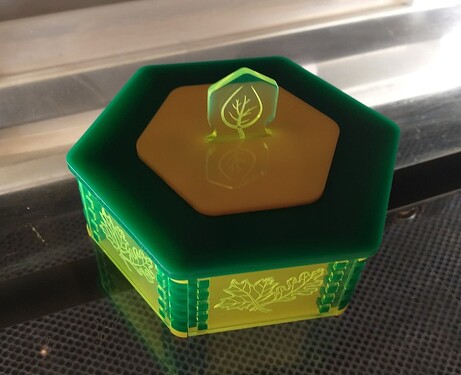

The color combination looks fantastic. I can see lots of uses for something like this.

I made a cuttle version of the file available. You should be able to make your own with it.

I will have to re-create it a different way to make one with more than four sides like @ESteele version.

I love the elegant solution. For both you and @ESteele , it would look cool with acrylic corners and wood sides/top. Just use @caribis2 's idea about measuring the stacks to get the wall height.

That could create a cool effect.

Very clever. Looks great.

I love the way you designed this. Just wish you would submit this so I could get the plans. This is a beautiful way to use some scraps. Thanks for letting us see how it looks before assembly.

As you undoubtedly know, it is against forum rules to ask for files. That being said, a version of this design was made available. Please read the fourth post above yours in this thread.

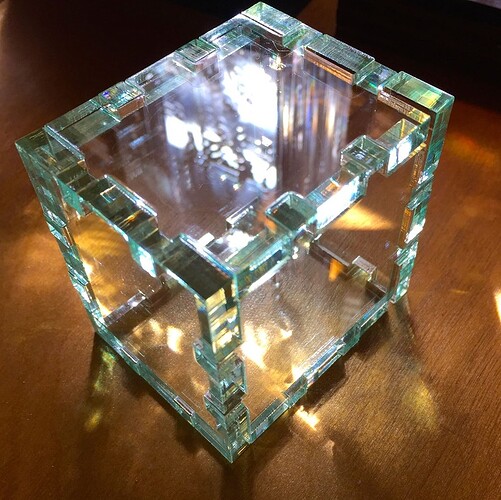

I tried skipping the spacers and only kept the fingers. It’s a nice look, but definitely a little more fiddly to get glued up. Of course making it in acrylic probably had more than a little to do with that. I really like this look.

@bwente, I’ll stop hijacking your post now. LOL

Beautiful combination of materials!

Also nice job of taking advantage of the sides for artwork.

Thank you! I think florescent green acrylic is my favorite material. Anything scored or engraved on it just pops.

I wonder how that would look with the “green glass” or whatever they call it.

Close…‘glass green’. Probably my favorite of all the acrylics. It would look stunning…just like a glass box.

Someone do it.

Closest I can get is this…my first acrylic box with finger joints…and my first glass green box…period. It’s really just a cube because I love the way it looks…so there is no opening in any side.

I call it “Sea Glass”. Making clear no color glass is a challenge as the slightest amount of iron in the sand causes that odd blue-green color. As much of the more historical glass had it and later Coke patented the color. Much broken glass worn round by the waves has become a special find they call “sea glass” and special because of it. The acrylic of that color is not about that but made to resemble actual “cheap” window-type iron-colored glass.

I cannot see it without recalling the history and how the color was hated, But it has a great place now.

It is similar in color to sea glass, for sure. I have a real piece of sea glass, but it is more frosted looking than clear.

It is the bouncing around in the sand that does that ![]()

I am going to have to get my hands on some of that. It looks amazing!

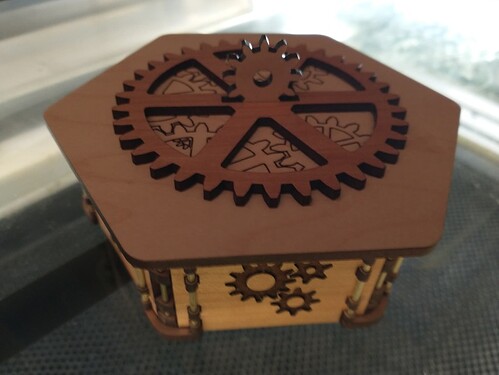

Ok, so I’m a huge liar, apparently. I’m going to hijack this one more time. This is just such a cool design process, I can’t stop playing with it. ![]()

This time I tried a little multimedia, wood and brass. I also tried different join gaps. The brass rods are placed in a way that locks the joints into place against the walls. The only ones with any glue are the top and bottom ones that touch the base and upper ring. It’s very solid. I did over compensate for kerf and had to force the rods into place, which did cause some de-lamination of the plywood in a couple of places. That being said, I’m very surprised how well the proofgrade plywood holds up when cut thin.

@bwente, I’ve spent about 15% of 2022 in Inkscape and Cuttle, and assembling parts. It’s all your fault! ![]()

Wow! Now we’re talking.

I love the rods and the spacing of the stacks. I tried last night to get setup in cuttle to make a parametric file, but I am not sure which approach is best.