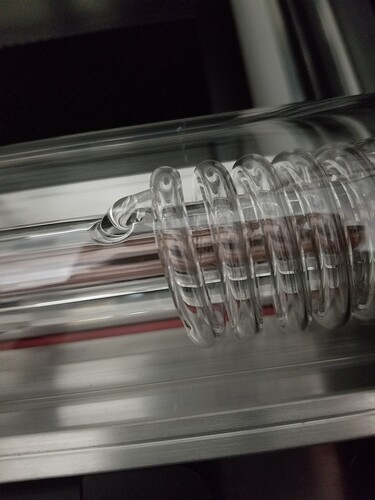

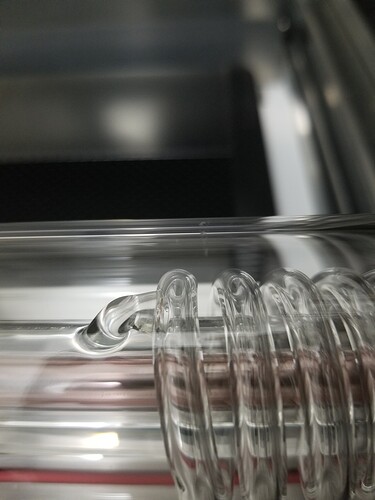

I hope someone can help me with this concern as I am a new owner of a GF plus unit. As I was unpacking and inspecting the inside of the GF today, I did notice a scratch or hairline crack on the outer laser tube. It is vertical and about 1 inch long. I does not seem to be glue or something of that sort. I have contacted support and I got an automated response saying someone will get back with me within 3 days. I am wondering if this is an issue someone has dealt already with and can help me in the right direction or if I should by no means try to use the machine. Any help or insight would be greatly appreciated.

Sending email and putting a note here opens two tickets that will slow things up a bit, but what they will ask is that you get photo documentation of the problem and post it here so the details can be seen. Then folk can see what you are talking about. meanwhile I would not go any farther with setting up the machine.

The outer tube is not pressurized but is full of coolant (or will be, once you run it for a while), so there’s no harm in running the machine as long as it appears to be dry inside - just keep a close eye on it (which you should be doing while it’s running anyway) and see if there’s any leak while running. Keep a towel handy!

Pics will likely be requested by support.

Thank you! I am adding pictures now

. It is very difficult to see, but it is the vertical line at the top.I see it. Can you feel it when you run your finger over it?

I’m sry to hear your gf came damaged, but i am really enjoying seeing a nice clean laser tube lol.

Seriously, mine looks like a frat house floor the next day…

If you want to distinguish if it is something on the tube or a scratch, a razorblade will either take it off (something on the tube) or catch (a scratch). It doesn’t look like a scratch to me.

Scrape a blade across it a few times and you will know. My horse sense tells me even if it were a scratch, it wouldn’t affect the operation of your machine

Enjoy the nice clean machine, it wont last.

Welcome to the adventure!

I just spent an hour cleaning my  the other day and it is already covered in a thick layer of shmoo

the other day and it is already covered in a thick layer of shmoo

Yes, I feel it when running my finger over the line. I thought it could be glue at first, but doesn’t seem the case.

Thanks, that seems reassuring. I just want to make sure it will be safe to operate and not have a serious safety issue.

I have to agree on the razor blade test. It looks like a schmear more than a scratch.

But if it’s a scratch the tube will fail as it’s a weakness in the glass envelope. It might not be soon, but there’s stress concentrations around scratches on glass envelopes.

Interesting.

I have a friend in the commercial glass business, he told me once when you score glass to cut it, you want to make the break right then because the glass begins to “heal”. I understand that a scratch represents a weaker spot in the structure, but eventual failure there surprises me.

Is there any internal pressure there besides the coolant weight?

I am just worried about it bursting or cracking at some point because it is near the inner glass coil. Not sure how much heat goes through the middle part, but for the price of this machine I sure would not want to have this issue. I guess I am just going to wait for an answer from GF. Thank you so much for all your help out there. It is reassuring to have this forum.

That’s a new machine, if it proves to be a scratch, I would ask for a replacement.

There are many discussions about glass movement but the observation that stress can break glass years after the initial cause of bad cooling or incompatible chemistry suggests that there is no movement even after many years. Cuts by a glass cutter do get "stale"in a matter of hours but I think that it is more about a proliferation of tiny discontinuities (too small to be called cracks) that can send the break off other ways than intended compared to a fresh cut.

The cooling system is not pressurized.

I didn’t think so, but James has infinitely more experience with lasers than I do.

Thanks for your patience @KDS. I’ve just followed up to your support email. Since we’re working on it there, I’m going to close this thread.