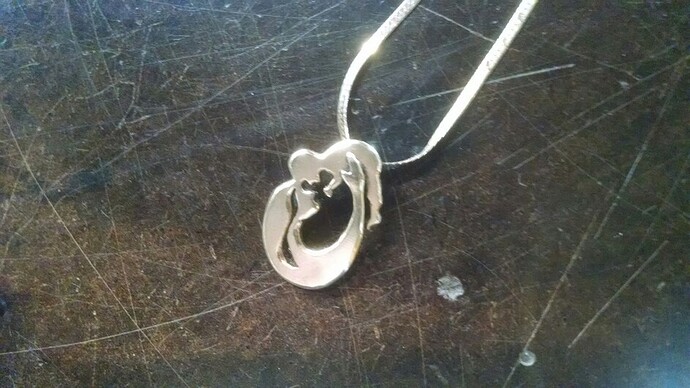

A Mother’s Day gift, not my design. My Wife saw this on a co-worker and took a pic to show me. Fashion jewelry in cheap metal.

I reproduced it as closely as I could to honor the great design. No idea who to credit, but they nailed it. Salute to the original artist!

I embellished the finish by blasting with flint shot (glass bead) that leaves a smooth matte finish, and beveled the edges and burnished them. Done in 14k, (bad picture, looks silver) precious metal befits the wonderful design.

One of her favorites.

21 Likes