I made a project in fusion360 which was sent to 123Dmake a while back, which is basically the same thing. It was before I had the glowforge, so it was done on my other laser.

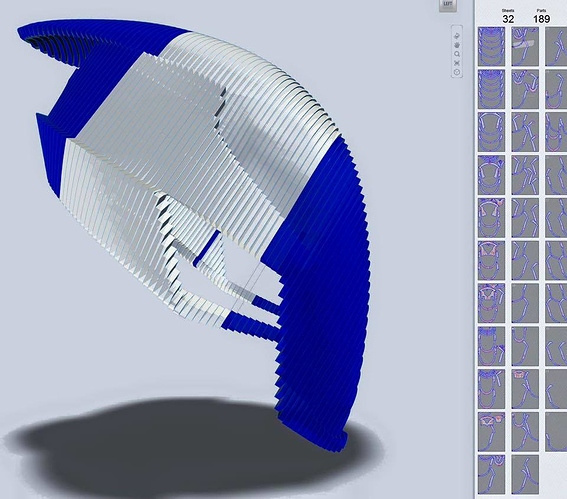

I made a couple of things here, a solid helmet skeleton made of foamcore cut out of 32 sheets, and a scaffold to support the visor of the helmet which was also modeled in fusion afterwards and sheeted out in 123Dmake

Heres a link if youd like to see the process I went through:

I hope theyve fixed the wandering hole issue in the fusion release.