Just ran the first trial after making sure my venting system was air tight with silver tape on all connections. Running the hose to duct work through a wall to a dryer vent set up. Ran the little measuring design, watched the smoke venting nicely but a seeping smell of burning wood came out…not to terribly unpleasant but surprised me. After opening the unit to remove, the smell filled the room and went through the house…massive headache and nausea. Used the draft board. I am super sensitive to smells…but this is scary. Does the 1200.00 unit take away smell or are the seals on the machine not adequate to keep the odors in? No smoke escaped. Really want to love this machine but I have been down 3 hours ill now…every door and window open for an invisble smell…45 degrees out!

Yep, I got that headache too for a couple of days. (Turns out I did not have the venting sealed as well as I thought I did.) ![]()

Make sure you wait for about 30 seconds after the job finishes before you open up the lid…there is usually a little wisp of smoke that lingers after the job is finished and you need to give the fan time to suck it out. Also, peel off that masking and pitch it as soon as possible…in a ziploc bag helps. It holds the tar from the burn, and that’s stinky.

Welcome to the forum.

I am sorry your first experience has caused you to be ill.

Whenever you open the lid, you will have some odor as the material cut retains the smell and there is often smoke trapped under the item that was just cut.

I think you would be well served by an additional inline fan to increase the air flow of your exhaust. The advantage of the inline fan is that you can leave it turned on for several minutes before opening the lid of the Glowforge.

migraine worthy headache! I have the hose taped into metal duct through a block wall that used to have a wood burner chimney…not sure where it could leak.

Is the flue open?

thanks, I tried a small booster fan in the metal duct…am wondering if the expensive filter system would work best. I know I am bad on smells…make a perfect canary in a coal mine this nose of mine

yes…as it was the first run my son stayed inside and i went out to feel how much pressure was coming out…lots of air flow…enough to move the grass around.

My son is suggesting setting up a ‘tent’ of plastic around the entire operation…hmmmm

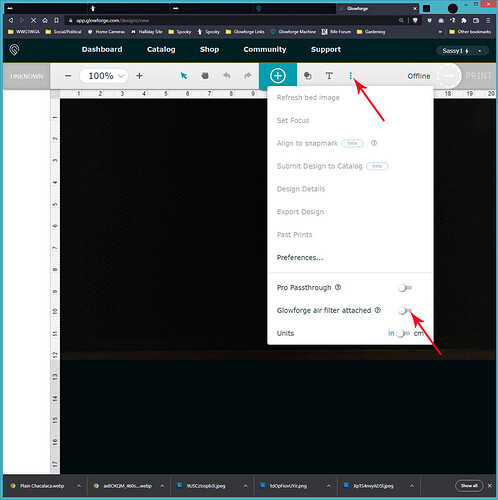

How far is the run? (About eight feet is all it can handle. It needs to have two or fewer 90 degree bends too.) And if you are using a booster fan, you need to switch off the internal fan in the Glowforge app. Click the info dots, then the Use Air Filter switch.

If the venting is working as intended, the entire machine is under lower pressure. There should never be any smoke or odor coming from the machine.

In over 4 years of operation, I have never had the slightest hint of smell from any material.

thanks, we tried it with the gf fan on and ran a second sample with it off to see if it made a difference. It has two gradual curves…one right off the unit and the second as it curves to the wall…may be about 5’ of house before entering the duct work.

Your duct work is probably the issue. It won’t have the gentle curves. The machine is designed to vent directly out of a window.

Wow. Do you vent directly to a window or have you set up a permanent path?

I do now, but for the first year or so I just opened a door and threw the hose out there.

I just spoke to another maker who said the acrylic smell drove him to finally purchase the expensive filter system…that with a 6" inline he still could not stop the smell. I wonder if there are discrepancies in the seals from one machine to another.

The machine is not sealed, by design. That allows the exhaust fan (or external inline fan) to draw air in, preventing any smoke/odor from escaping.

as an inlet…ok, duh me, thanks. So, I will move the unit to a window (so much for my esthetic), shorten the run to a window and purchase an inline fan as first attempt to mitigate. Thank you all for helping…really don’t want the expense of the filter unit if I can avoid.

The filter cartridges can have a VERY short lifetime depending on materials, cost $250 to replace, and have been out of stock for a long time with no expectation of them being available any time soon.

Wow…I may just buy up some extra plastic and create a semi clean room as a back up!

Thank you for that information!