Love this thread - we’re not working on this now, but it’s wonderful to hear what you all are thinking of for it for when the time comes!

OMG, you played the Trump card! ![]()

That deserves more than a like …![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

As far as 3d printing goes, what’s the distance between the bottom of the machine (crumb tray removed) and the glass at the top? The 3d printing head wouldn’t have to have the same restrictions as the laser.

Yes on vinyl cutter. Yes on inkjet/spraygun/whatever for printing on wood/plastic/fabric/whatever. Yes on diamond drag thingy (don’t even know what that is.) Yes on tiny hands.

I think, after the solid platform of the laser is established, as many of these things as possible should happen. It’s my first and only machine of this kind, and bound to remain the only. I can buy more accessories for this machine. I can’t buy more machines. So says the boss/wife.

And a pick and place head!

I’m in the same boat. Limited space in the office, so limited on toys.

I could see an embroidery/sewing head being feasible.

so if we had an extruder and the laser head wouldn’t that be like having a pencil and eraser only in 3d?

I love the idea of an inkjet head. When I first learned about 3D printers, I thought it would be a good business model to offer architects 3D models of their designs complete with floor and wall coverings in color. Or for kids to have a doll house that looks just like their own house. Printing on plywood before cutting should work well for those kinds of projects.

I could see the potential for a longer focal range laser head. For those times you need to cut through something really thick…

Cut through to ~.5inches with the standard head, then switch to deep cut head for continued cutting.

but what if they go with a resin printer?

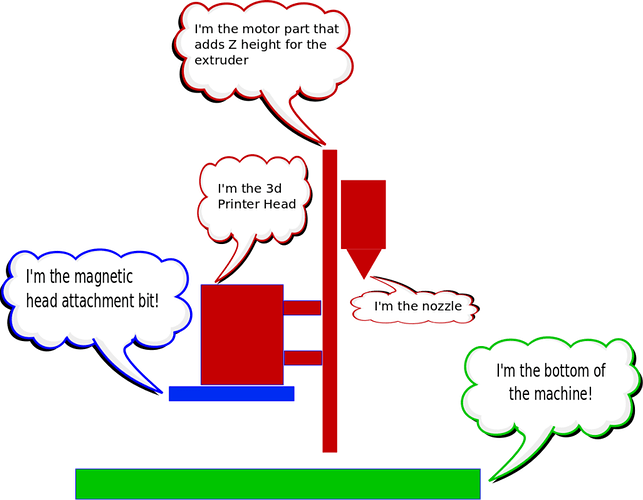

I think you need the nozzle to be the lowest part! Otherwise the Z axis will nock over anything you build.

I don’t really know much about those. Can you draw it? Be sure to include the thought bubbles.

So, you mean shorten the lowest bit of that tall rectangle to the height of the magnetic head attachment bit? Sounds reasonable to me.

3D printing would probably suck pretty bad unless they have some crazy ideas. No heated bed, small Z, nowhere for filament to enter the machine unless you have a passthrough, fan will vent all the hot air out.

If I had to vote for attachments this would probably go towards the end of the list.

I want the color adding head to be at the front of the list. ![]()

Maybe there’s a plug for bed accessories, too. Plug in your heated bed or some sort of chamber to contain CNC sawdust or whatever. Or, Proofgrade PLA. Doesn’t that have less need for a heated bed?

I’d say carve it, then print it would that application progression. Also, there is likely a printer that could print on a slab of wood or stone, but why have a whole new machine bed and controller when you could possibly just pop on a new head with ink formulated for your material.