Each time I use the proofgrade acrylic, using the support tray, on the edges where the cuts happen the paper backing on the proofgrade acrylic seems to burn around the edges, and some of it damages (leaves black marks, gouges) on the acrylic itself. It is in the pattern of the support tray (the honeycomb of metal), so it seems like where the laser hits that. What am I supposed to be doing so this doesn’t happen?

Speed it up or lower the power a touch. Or put a sheet or two of newspaper or copy paper under it first. You’re getting flashback from a slightly overpowered cut.

Thanks a ton, James! Since I was using PG materials, I assumed the settings for Engrave/Cut/etc. were worked out. Does it depend on the design? I.e. how do I approach it so I don’t have to use one or more pieces of acrylic to figure out the right settings each time.

Actually, since they’re proofgrade, I can’t adjust any of the settings for engrave nor cut. (That I can find)

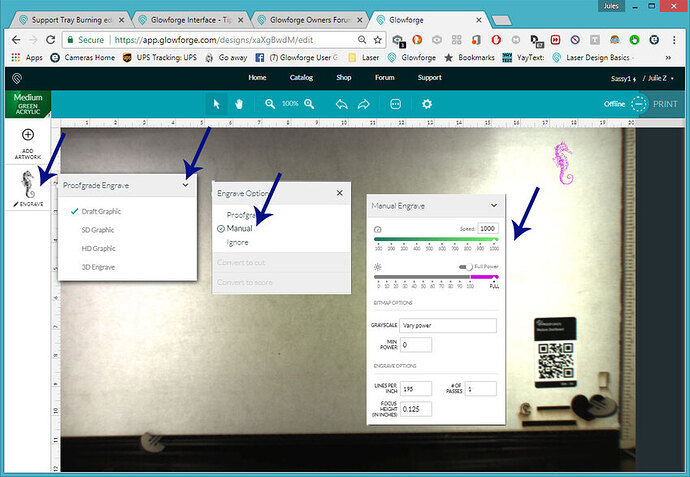

You can just adjust the settings using Manual Settings and nudge the slider slightly.

Once you have a Proofgrade setting selected for the material, the values for it appear when you switch to Manual settings. Then you can just adjust them slightly for different effects.

There are several handy tutorials that will get you started quickly using the interface - this tip came out of this one. ![]()

Do you mean the metal honeycomb tray is getting damaged? If so, you likley have the tray in backwards as the plastic edge of the tray should be out of range of the laser.

**Nevermind, I see you said it was the honeycomb pattern… That’s called “flashback” and it’s where there is too much power hitting the tray and scorching the back. Adjusting the setting like Jules suggested will fix it

I run a test pattern on materials. Wood will have some variability (a lot with some Home Depot type plywood) between different lots but once you’re in the ballpark there’s a fair amount of tolerance unless you’ve got it tweaked so it just barely cuts through.

Acrylic is really consistent though and the settings don’t often change except when the lens is dirty ![]()

Thanks so much, all of you. While I think the GlowForge is an amazing piece of hardware, I feel like the software / documentation are lacking. I supremely appreciate how fast and thoughtfully you all replied.

After a while it will become a bit more intuitive and you won’t have as many issues, I promise. After 6 months of using the GF, I really have issues from flashback or mis-cuts anymore.

Are you seeing the issue with multiple files or just one in particular? I use the PF settings even on my non-PF acrylic with good results as acrylic is pretty consistent from manufacturer to manufacturer. (Unlike wood.) I think flashback can have to do with the design and how may intricate a design is or how many nodes etc. The picture shows what’s about average for me as far as flashback. The small areas of discoloration are where I know the outline is node heavy. If I have a really intricate design I either dial back the power just a bit or up the speed. I’ve found that there is a little wiggle room with the settings and even going from speed of 125 to 130 can make a difference.

You can also add layers of tape over the back side so the flame is less likely to blast through and the tape will protect more when it does.

One place you are probably getting blow through is at any sharp corners.As the laser comes to a stop to change direction or any other start or stop the laser keeps going the same as it slows briefly causing the issue. One day soon they will have that fixed but not as yet. This is a problem separate from proof grade issues and shows up everywhere. You can reduce the sharp corners a bit by having tiny arcs instead of corners, and low power low speed will also reduce the effect but it cannot as yet be eliminated.

Thanks for the help in this thread, everyone! And thanks for the feedback, @glowforge17, I’ll be sure to pass it on to the team. If you run into any other trouble, go ahead and post a new topic. Thanks for letting us know about this!