Hahaha that’s the great part about the parties though…you don’t have to help out at all if you’re not signed up for that month! Of course, they may still ask for help with lasercut part favors, and in that case…I’d honestly probably jump at the chance to do it, who am I kidding  So long as the office will pay to make 'em!

So long as the office will pay to make 'em!

Those are so cute! You are an inspiration.

Thank you!!  I’ve found that it’s much easier to come up with an idea when you have an actual goal and constraints in mind. Before this I had such a frustrating mental block trying to come up with ideas for the glowforge…I wonder if there’s a laser cutter equivalent to all those online writing-prompt generators? lol

I’ve found that it’s much easier to come up with an idea when you have an actual goal and constraints in mind. Before this I had such a frustrating mental block trying to come up with ideas for the glowforge…I wonder if there’s a laser cutter equivalent to all those online writing-prompt generators? lol

Put the slot in their beak to hold a card (more horizontal than vertical but still “readable”) ![]()

Love it!! Think I may have new placecards for my Thanksgiving table now…man, I cannot wait for the next major holiday after I get my glowforge haha

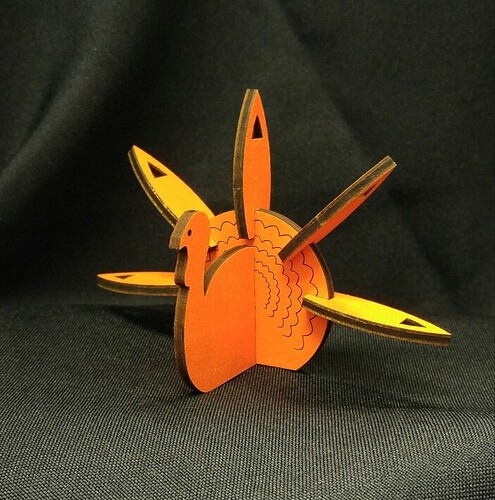

Had to do a fair bit of tweeking on this. For 1/8" baltic birch, the slots were way too wide. The stock I have runs about .124" thick.

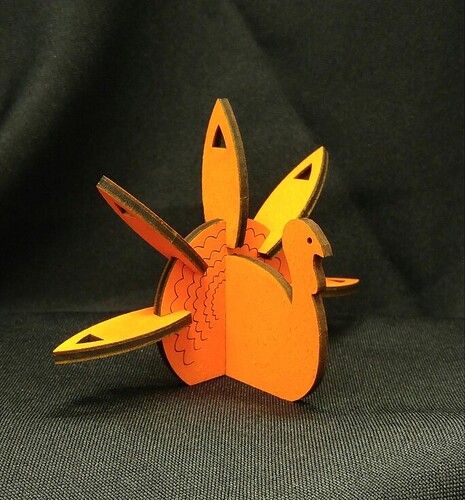

Also, don’t forget to use raster or vector engrave…added a bit of feathery look to the tail. As well as added an eye and cutouts in the feathers.

There is much more details that could be added but just did a few for example.

I had some scrap orange so used that…the lighting makes it look different colors though.

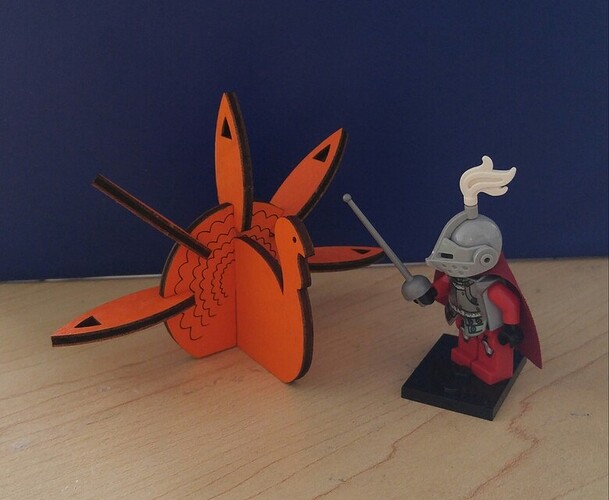

Size reference…the lego knight was hungry…he said the turkey tasted a bit dry…lol

Awwww…that looks great in wood! (I’m gonna make me some turkeys for next Thanksgiving!)

Here are the files for Baltic birch ply .124" thickness

Stephs turkey.pdf (10.4 KB)

Stephs turkey.dxf (175.7 KB)

You guys (as always) are freaking awesome.

In under 6 hours someone posts a design, and it becomes a reality. Not even my design and I love you guys!

Never change.

Come hither, my feathery friend, before I make dinner out of you!

Oh my gosh that is sooooo cool!!! Having major laser-cutter-access envy right now haha. The engraved details are adorable! And the cutout on the feathers is genius! Yep, I figured the tabs were going to be a pretty loose fit. Your post seriously just made my day

I’m feeling the same way. You beat me to it…and that’s why you have inspired me. Time is slipping away so fast and occasionally I really stop and think about what a short time it is now until we all get our lasers. SO exciting!

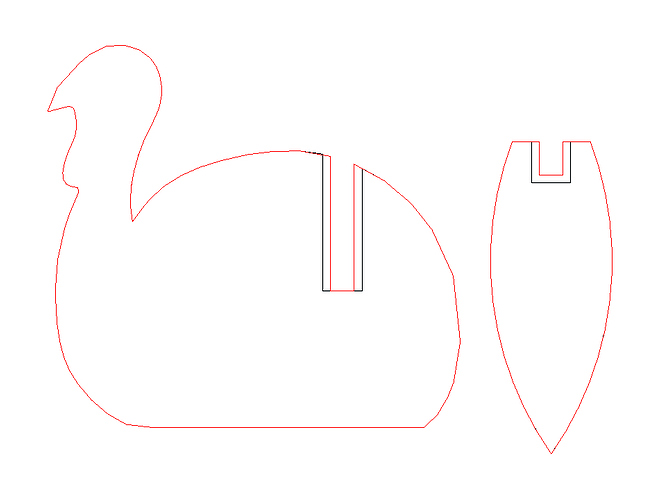

Yeah it was a significant difference in slot size.

I superimposed the correct size (in red) over the existing one (black) It would have fallen right out…lol

That is marvelous!

Yikes! Yep, definitely too big haha.  When adjusting for kerf, do you find it easiest to first start with slots the full width of the material, cut them, then measure the test cut to get your adjustment value? Or for common materials you work often with do you have a sort of ‘start point’ kerf value that you always factor into the initial design?

When adjusting for kerf, do you find it easiest to first start with slots the full width of the material, cut them, then measure the test cut to get your adjustment value? Or for common materials you work often with do you have a sort of ‘start point’ kerf value that you always factor into the initial design?

@Xabbess Thanks! I think one of the coolest things is seeing all of the awesome designs that were inspired by topics on this site. Tell me about it!! Like, right now- how is it already the end of October?? What happened to September- heck, even August! If I didn’t have grad school application deadlines looming ever closer I’d be very happy at how fast the arrival of our 'forges is approaching

@dan this forum is marvelous!! I never thought I’d have the chance to find a site so inspiring, encouraging and friendly- pretty sure I never would have made the turkey otherwise.

I record kerf measurments whenever I start working with a new material.

Easiest way is to cut a 1" square, then measure it with calipers. The difference/2 is your kerf. Most of my 1/8" woods are .006".

Always use calipers if you want a snug fit…

When doing a perpendicular fit like these, take width of material minus kerf×2. Thats the slot width.

I generally design for whatever material I plan to use.

Awesome!! I see kerf templates in my future…and a better set of calipers haha.

Here’s the set I recommend to my laser class students. Not too expensive ($20) and good enough precision for what we do: Amazon calipers

Ooooooh very nice! Thanks!!

I got mine at Harbor Freight on sale for $10…same ones as on Amazon. Pick up some extra button batteies too… it’s always a pain when you’re in the middle of measuring things and the batteries go dead and then you have to go out and get them LOL