Sorry to keep you all waiting. Without further delay here is my second post in the Chinese Laser Experience (thanks @jkopel lol)

Assembly:

The laser comes with the laser unit, a water pump, and a fan. The water pump is submersible, and I had a pot sitting around I use for vaporizing acetone to smooth 3d prints, so that will do for now. This feels incredibly unsafe and destined to have issues. A lot of people put these on the floor just in case. For tonight its here so I can get all the air bubbles out.

Next is the fan. If you look in the picture above you can see a thin slot and some mounting brackets for the fan. It is WAY taller than this slot, and the mounting pieces on the fan are much thinner than the allotted space. Luckily I had some HDMI end covers sitting around that were the right size to take up the slack. I covered the open part in the top with some cardboard (cant say I dont have some to spare haha!). It moves some air, but feels really ineffective when inside the unit. Either way, its attached and doing its best.

Alignment:

Next up is the alignment of the beam. So many things to take into account here. There are 2 mirrors with 3 adjustment knobs on each. You have to move the carriage around and test reflection from each one in the proper sequence to make sure you are getting a perfectly aligned beam. Unless the carriage is bent and unsquare which im starting to think is the case with mine after all that shipping.

In order to tell if a mirror is aligned properly, you block off the next mirror down the chain with a piece of tape or cardboard or anything you can see that will get a burn mark from the laser. You then move the carriage to each corner of the bed to see if the marks land on top of each other. If they do great, if they dont, well… they probably wont.

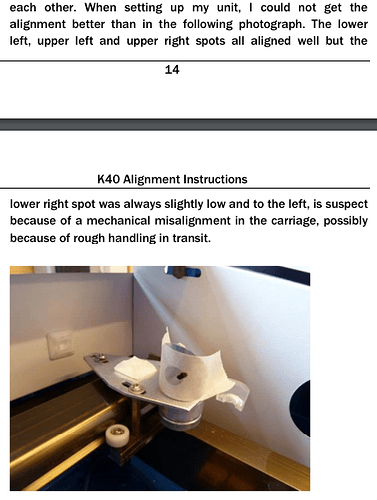

As you can see in the following picture, things arent lining up quite so well out of the box

And after another hour or two of messing around with it, it seems its only out of alignment in the bottom right corner. You can see the remnants of all my attempts! I could make an abstract art piece out of these haha

So after all that it seems im going to have to do a little more investigation into whether that corner is really out of square or not. Everything in this unit wobbles and wiggles, and when you try to move the carriage you can tell that if you moved it back it wont be in the same place it was to begin with. No rigidity here.

Having said that, its about time for Game of Thrones to start, so Im going to call it a night on laser work. Ill post more updates as they come!