One last simple print to round out the week…this is that jewelry tree that I created last year, and I wanted to show you guys a couple of things with it…

The smaller one in the front is cut from Maple Proofgrade ply, the larger one behind it was cut from Lowe’s 1/4 inch Birch ply. I removed the masking from the Proofgrade before cutting it, because I actually wanted that smoky residue…turned out pretty cool I think. (Definitely more interesting.)

But what I wanted to show you was the difference in how regular plywood cuts versus the proofgrade, and it’s pretty hefty.

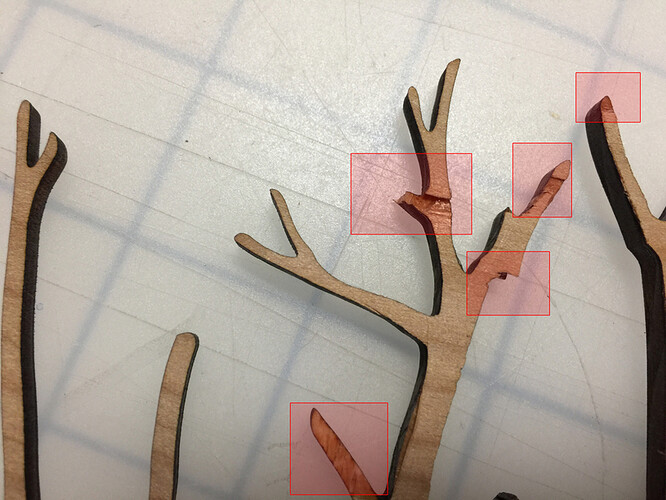

This was the first trial on the plain plywood cut - I had to arrange the cut around the knots in it, and tape the sheet down all around because of the significant warp in it. (You can actually see the warp where the cuts fell down into the freaking holes! Chuckle!)

But that wasn’t the bad part…either because of the warp, or because the wood was unevenly dense - the cuts did not go all the way through on some of the little branches at the top of the tree. It was close enough to try to “liberate the tree” using a very thin knife. Meh…results were not great. It’s actually missing a couple of branches there in one spot. And it took a very long time to try to do it.

Okay, so I thought i might have the same problem with the Proofgrade.

I didn’t by the way - it cut through completely without any further preparation necessary on my part, but I didn’t know that at the time.

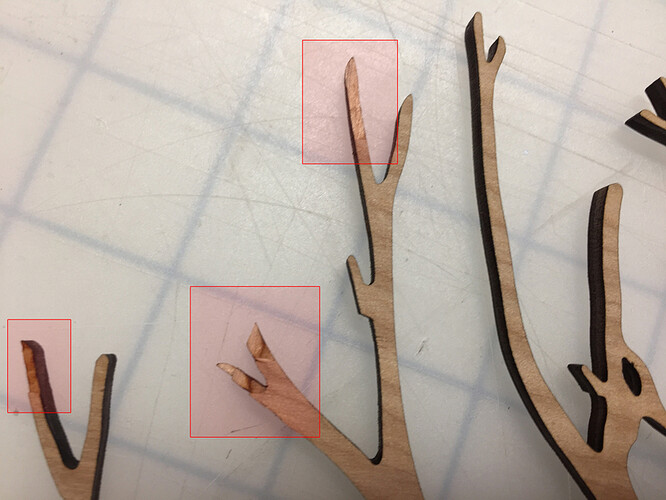

But I still want to show you a trick that you can use on files like this one, that have a lot of very thin branches that might be difficult to remove from the surrounding waste material without breaking something.

Give yourself a few weeding cuts:

Drag the cuts down into the curves and connect them to a box around the delicate object to be removed, and you will eliminate any removal problems.

Besides, it makes for a very cool-looking puzzle effect, and I think I’m gonna have to experiment with a few of those down the road too… ![]()

It took the stain super-evenly with no retouching. And I’ve done several other pieces now in other stains, even a lamp that was ebonized with black tea and iron acetate – nice, consistent staining on both sides every time. One side is totally clear, the other is slightly knotty, but the knots are small and tight, and there isn’t usually any attempt to messily putty them with patching plaster like on some of the other plywoods I’ve seen.

It took the stain super-evenly with no retouching. And I’ve done several other pieces now in other stains, even a lamp that was ebonized with black tea and iron acetate – nice, consistent staining on both sides every time. One side is totally clear, the other is slightly knotty, but the knots are small and tight, and there isn’t usually any attempt to messily putty them with patching plaster like on some of the other plywoods I’ve seen.