Cool! And you zap things barefoot.

Haha! Fingers crossed you don’t get the third tier invite!

Yeah I think the floral graphic would look awesome with a lighter color on the walnut!

Also a note from your Friendly Neighborhood Stationer have them handcancelled!

You shouldn’t need fiducials, the corners should be sufficient. If the GF can orient a doubled sided cut by looking at the edges it should be able to auto centre any artwork to a blank sheet. In this case you would pretend the jig is the sheet you intend to cut from. Place it anywhere and then ask the GF to align your artwork to it.

Sorry to sound like a broken record but if GF can do double sided cuts and pass through alignment with the cameras is should be able to align to any vaguely rectangular shape to a very high degree of accuracy. However we have never seen any evidence it can do that, just lots of talk of jigs and fiducials. This makes me think it is vary long way off doing camera alignment.

Amen for numeric positioning!

No.

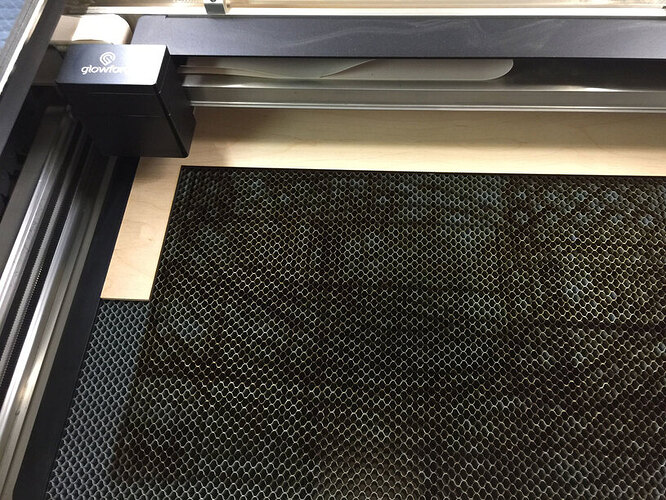

I think you could accomplish this just as easily with a simple piece of rectangular scrap pushed against the rear wall, but I haven’t tried it.

Very cool idea!

Please don’t take my discussion with the members of this forum as evidence of anything other than my enjoyment of talking with members of the forum about the topics that interest them.

Isn’t there a gap between the back of the tray and the rear wall? I didn’t look deep inside when I was at the MakerFaire and I don’t know that I’ve seen anyone’s photos show that area. My other lasers have a gap between the front & back of the materials bed so a piece of scrap would fall down. Unless I used some kind of solid block of wood.

I am just surprised you don’t say Glowforge has two cameras so you won’t need jigs for alignment. I can see the point if you have lots of small things to do in one go, like a rack of pens above. But for single sheet like @takitus’ example it seems that it shouldn’t be needed as soon as the double sided work is completed.

Even multiple items should be possible to be auto aligned eventually. I.e. throw in a bunch of pens and say auto align a pen shaped piece of artwork to all of them. It wouldn’t be hard with OpenCV to find all the pens with the lid cam and then send the head cam to locate them precisely, calculate the geometric centre and align the artwork relative to that.

It would be a major selling point and it seems not much extra work compared to what is needed for two sided mode.

No, the tray runs all the way to the back wall. (Easily will support a jig…it’s what I did for the early tests I ran…created a backstop for the printable area. Worked a treat.)

I haven’t mentioned it here because it’s going to change.

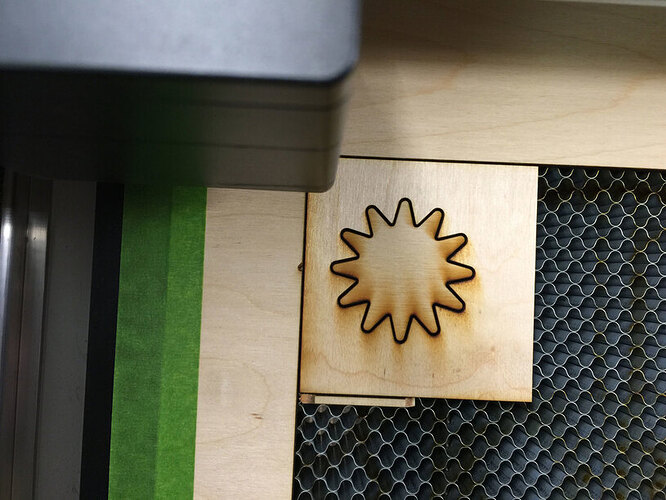

Engraves on stars after they were cut. (Secondary operation.)

Worked perfectly. I didn’t always get results that good with an optical 3-point registration system, and that process is a lot slower, since the machine has to run through the routine of finding the registration marks.

I’ll probably keep using jigs - it’s a hell of a lot easier.

The only way to tell if a jig is really reusable with any accuracy is to remove everything from the laser, and put it back in again and see if you can get an exact cut. So take out the jig, take out the bed, close the browser, then put them all back in, reload the file into the GFUI and see if you can cut exactly back through what you just cut through before without any shifting etc.

Scores work great for this. Do a score on something before removing everything, then run it again afterwards to see if it all lined back up. Its not easy to accomplish. The glowforge has a few things about it that make it especially difficult, like the fact that the feet of the bed shift around in their slots a bit.

I did close the file to test it.

Currently the system they have set up does not allow for repeatability if you close the file. You have to recut the secondary jig once to re-establish the relationship between the vector outline and the engraving. But after that one cut you can drop as many blanks into the secondary jig as you want and just keep sending the engraving to be done. They all lined up perfectly.

But with that small caveat, it works just fine for repeatability as long as the file is created correctly and the relationship established between the vector and the engraved lines.

(I offered a suggestion as to how they could make it repeatable after closing the file. I don’t know how feasible it is given their coding structure though, so we’ll have to wait and see what they come up with later.)

If nothing else, it gives us an accurate way to deal with multiples in one session, and not a bad method for dealing with one we forgot a month or two later. Just have to do one cut before repeating the engrave operation as many times as needed.

Edit: To clarify - the method of using the dual jig system that I described above does not work repeatably if you close the file, as the current GFUI stands. If you are currently testing one of the machines and want to re-use a jig months later, set your jig system up the way that @takitus has described above using a 12 x 20 artboard.

To make it repeatable in-between jobs. Make the source file 12x20 then place yours assets inside that.

They put a hack in for me to take care of that issue (which everyone can use). I mentioned it in the original post.

But the whole point of most of my discussions regarding this is not having to cut the jig again. complicated jigs can use up a lot of material and shouldnt need to be cut again between batches if everything was done properly. Im hoping they will get to the point sometime in the future that recutting jigs every time you want to do the same item again will not be necessary

@jules ^

I wanted to create a jig that defined the printable area.

It’s more handy to use that for me, since you have to essentially create one large jig for each project if you float it in the center of the printable area.

With the 2-jig system above, you can just butt whatever sized secondary jig you need to use against the stops that define the printable area. Large or small. (Uses less wood for small jigs.)

Either way works, and we still don’t know what they’re ultimately going to do, so I’m flexible until then. I don’t foresee needing to do a lot of repeat engraving on projects, but if I ever do, I can use that backstop, and not have to precut a lot of sheets. (Just use up little scraps. Which are starting to pile up rather badly around here.)

Its cool that youre experimenting with jigs, but please dont go and tell everyone here that certain things arent possible after I just told them that it is. Its pretty confusing. Thats what half the whole post was about. Being able to create the most reusable/accurate jig possible at this point in time on the GF.

The main issue of repeatability was never about it being in the same session. I can do that all day long. Im not sure if that was clear or not, maybe it wasnt and that might be my fault. However, it is a discussion that was brought up many times before.

To further the confusion youre making incredibly vague comparisons between making a simple jig that wouldnt have accuracy issues to begin with, and comparing it to an unknown 3 point optical system with no real information there. What system are you talking about? What kind of tests are you running to compare the two? What kind of margin of error are you seeing between the two? Are you creating an environment where it would even be possible to have a margin of error on the glowforge? Does this even relate to the ability to recreate certain engraves over time without any error in a place where you would be switching out jigs?

Im glad you are trying to help, but the fact people are liking your post is a little upsetting because it is spreading contradictory information to what ive posted, that I know is incorrect, it doesnt build on top of anything ive written, and when you mention suggestions that could improve the UI, you dont say what they were.

The whole discussion we are having is about NOT having to create a new jig every time we return to do work. Some jigs can be very complicated and time intensive. Cutting a jig every time is something we already know we can do, and it is the worst case scenario. This is a CNC machine and should be able to use a previously created jig with sub-mm accuracy.

I liked your post @takitus ![]()

In all fairness, thanks for clarifying - I was wondering what the “3 point optical system” was.

Now I’m confused…what exactly did I tell them was not possible after you said it was? All I did was mention the jig testing I did, the results I got, and why I was doing it that way.

The alignment systems i was specifically referencing in my statements were the ones used by the Gazelle cutter. It has a 3-point optical alignment using registration marks, but they are not anywhere up to the caliber of the ones used in the Robomaster based cutters. (And sorry, but that comes from about a decade of experience, not specific examples. I was just joining in the conversation, and indicating that I have some experience with optical alignment systems. Five of them - across different brands of cutters. Don’t have any specific results to try to convince you with.)

That’s right, I didn’t mention them here. I gave them to Rita, and it’s up to Glowforge to decide whether to implement them. Not us. If they are unworkable, I don’t expect to see them in the interface. And that will be the end of it. Whatever they decide is going to be fine.

Yes, I know. They also know. Whatever method they eventually implement will no doubt take care of it.

What I am doing, (and what you did as well), is pointing out that there are alternate methods of dealing with the situation if they do not get your preferred method of 0,0 origins and numerical placement implemented before the release. And i know they will not be installing a 3-point optical alignment system, because I had that conversation with @dan several months ago on the forum. Trying to switch things around late in the game can cause further delays, so I let it go.

I am entitled to my opinion, and in my opinion, the jigs work just as well as optical alignment systems I have seen. You don’t have to agree with it. And it’s not a personal attack on your jig method.

Any changes to the alignment system are extras that were not included in the promises for the inital release.

People might need an alternative in using jigs, which other laser users also use.

I have a method that works in my opinion, and it’s one I intend to use. You absolutely don’t have to if you don’t want to.