Hiya! I searched the forums but didn’t find a solution, so I’m hoping someone here has a quick fix to recommend for one or both of my issues. Last time I contacted Support, I was left waiting for two weeks before I got help, and I have customers already waiting on their orders. >.<

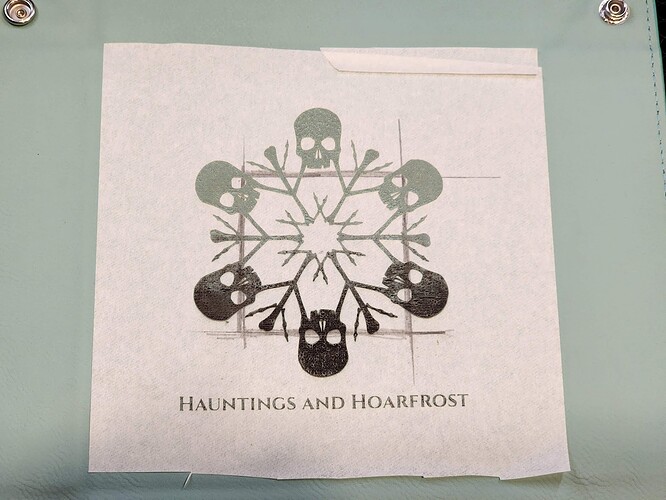

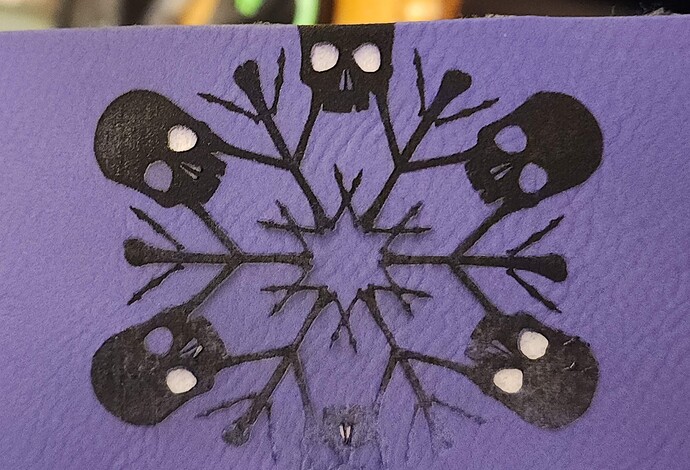

A couple of months ago I started noticing subtle variations in the color of engravings, which looked like a power or focus issue; one end of a piece would be charred black, while the other would be too light. Then I started getting uneven cuts, where some parts of a large design would not be cut completely through. This has been getting steadily worse, and now it’s going in stripes across the bed:

It’s worth noting that these two engraves were done sequentially, and the gradient reversed between them. The area of the bed that was lighter on the first one was darker on the second one.

If it were just a solid gradient top to bottom, or if it were consistent, I would assume that one part of the track mechanism was out of alignment and causing the head to get lower in one place, but I have no idea why it would go in sections like this, or why it’s really bad sometimes and barely discernible on other pieces. It happens on all the materials I’ve tried, and with many different cut/engrave files.

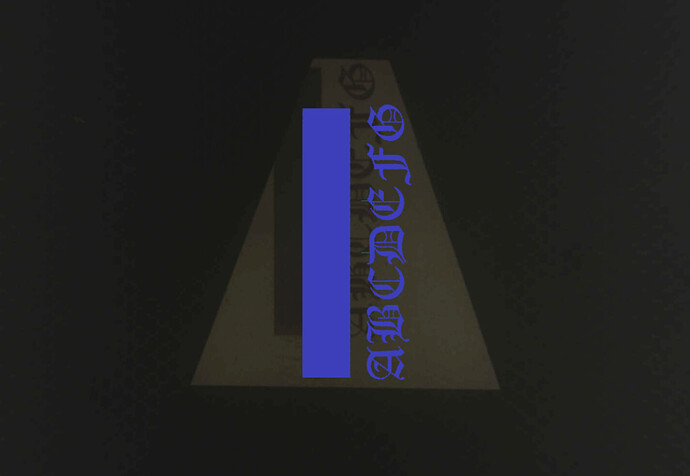

And then – as if that weren’t enough of a problem – while I was running tests on scraps of draftboard today, trying to find a pattern in the engraving issue, my camera alignment just COMPLETELY went out the window. This is what it’s doing now:

I have cleaned everything and swept/vacuumed out the area beneath the tray and the divots where the feet sit. I have tried turning it off and on again. ![]() But I’ve had about $60 worth of materials go up in (inconsistently burned) smoke just today, and I’m running out of both time and material.

But I’ve had about $60 worth of materials go up in (inconsistently burned) smoke just today, and I’m running out of both time and material.

Thanks for any suggestions or help you can give!

EDIT: After running the auto-calibration twice, I think we’ve got the alignment back to normal. Not sure why it randomly went out when the machine hadn’t been moved or jostled, but it seems to be behaving for now.