would be awesome to figure out these steps for a glowforge. would be sweet to figure the cutting depth to leave behind the backing tape.

The Glowforge (or any laser) is brilliant for inlay! If I’m doing an unfinished veneer I can use the default SD Engrave setting almost every time. If it’s something thicker, use an engrave test on the edge of your pocket material and find the depth that works for you ![]()

This test is great, just make the boxes engraves rather than cuts, and keep it just off the edge:

Looking forward to see what you do!

I have found that almost every two color inlay has a contiguous and non-contiguous section. I therefore engrave the non-contiguous part, and cut out the contiguous part. This makes it a lot easier to put together.

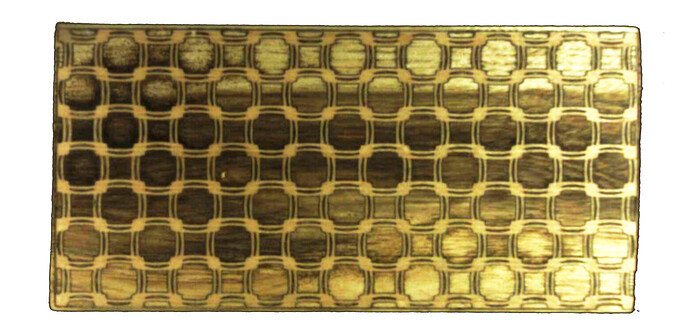

This was an experiment I did not expect to work so made a poor choice of materials …

this was 1/8 maple in 1/4 hickory and even the thinnest bits still came through. An interesting point is that engravings have little or no kerf so this was pounded into place before gluing and will never be removed even deliberately.

Funny how different perspectives can be. You said it was a poor choice of materials, and I say, “wow, that’s gorgeous!” I can’t imagine that it would be more compelling to look at than if you had done it “right”.