The straight connectors come 2 to a box. The 90 degree elbow is a single.

Still waiting on those connectors. Oh, the agony! But I did finish the real table for the Glowforge and got it off of the floor.

One thing to check is your window…I taped and retaped and used booster fans and was STILL getting a lot of smell in my shop.

One day I finally noticed that my nifty window insert (similar to yours) resulted in a large gap between the two window sections…I guess windows aren’t designed to be left half open. ![]() So I was venting it out, and that gap between the two panes let the smell right back in.

So I was venting it out, and that gap between the two panes let the smell right back in.

So I added some weather stripping between the two window sections…and the smell is finally gone!

AH that is a great observation!!! I am going to check that out right now.  Thank you!

Thank you!

Of course, there is a gap, just as you had said. And of course, the weatherstripping I have on-hand is not the right kind, so I need to find something else at the hardware store tomorrow. I need something that’s lower density so it doesn’t get torn off when I slide the window.

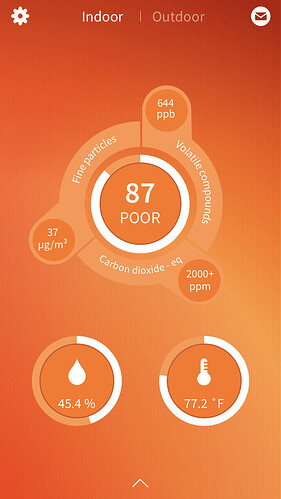

I picked up something from the hardware store that does a wonderful job of sealing the window, yet the smell persists. I guess I will have to wait for those attachments to lengthen the hose contact and then tape all of that off. Foobot says the air quality in my office is bad. I have my Molekule air filtration running in the desperate hope that it will help, but it doesn’t seem like it. My office smells like smoke everywhere!

Ran into exactly this last spring with my PRU. In my case, it turned out the weatherstripping itself was not gas/odor/smoke proof, being made to just keep rain and dust out. I backed it up with weatherstripping tape and boy howdy did that make a huge difference!

Still waiting on adapters, but in the meantime, check out this really nicely-designed duct fan I picked up from amazon!!! I think this will help keep air flowing through my office during cutting.

I have a similar model to this.

If the CFM max is 400 or 600 (or higher), consider a variable controller (if supported) used inline with the power.

The one I use is:

https://www.amazon.com/gp/product/B01N0ZSQRK/

This will help when you do paper/lightweight material from being sucked up (especially if you cut is the part you want to keep).