Follow up: Material Thickness does not change the physical location of the cuts.

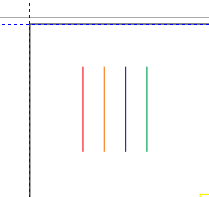

I created a test file that consisted of 4 score lines spaced 0.125" apart. Using my Corel template, Corel Draw alignment for a repeatable setup, I positioned the lines starting location to be at

(0.312, -0.250).

{Screenshot from Corel Draw}

Setup Parameters

The Glowforge was loaded with Medium Maple Hardwood:

Manual Score settings for all test cuts was: Speed-125, Power-11

Focus Height automatically set based on entered Material Thickness

Material Thickness varies: 0.01" (minimum allowed by the UI), 0.125", 0.250", 0.375".

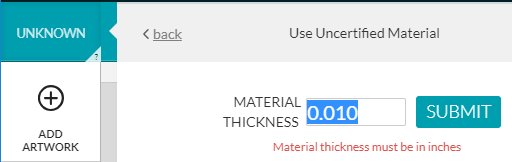

First score line - Override Material Thickness to 0.01"

Scan after the cut.

Since thickness was set to 0.01", the system translated the proposed location based on that value. However, you will notice that it actually scored the line 5/16" away from the left edge.

Focus Height and Material Height do not actually change the location of the cut, they set the focal length offset to set the laser’s convergent point relative to the actual top of the material as determined with the Red Laser scan of the material.

Second score line - Material Thickness set to 0.125"

Scan before the cut.

Notice that the artwork is now aligned with the first score. This is because the entered thickness matches the actual material height.

(It’s not perfectly aligned, but it is within the 1/4" accuracy stated by Glowforge. Especially since the image is near the top-left corner of the crumb tray, this is pretty good)

Scan after the cut

Third score line - Material Thickness set to 0.375"

(Yes, forgot and skipped 0.25”)

Scan before the cut.

Notice that the system has adjusted the image placement relative to the perceived material height of 0.375"

Scan after the cut. The third score line was cut 0.125" to the right of the second line, as defined the in the svg file.

Fourth score line - (I picked up the missing thickness) Material Thickness set to 0.250"

Scan before the cut

Scan after the cut

For a final scan view, I let the Glowforge auto set material based on the QR code for Medium Maple Hardwood. Notice that all score lines are equally spaced and within the systems accuracy limits.

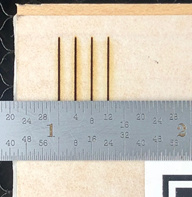

Actual result

Photograph after the four test scores

Final Inspection - Measurement were checked with a 6" Starrett steel rule

The first score line is 5/16 (0.312") from the left edge

The top of the lines was verified to be 1/4 (0.250") from the top edge.

The spacing between each line is 1/8 (0.125")