From the results I’ve been seeing, I would say yes.

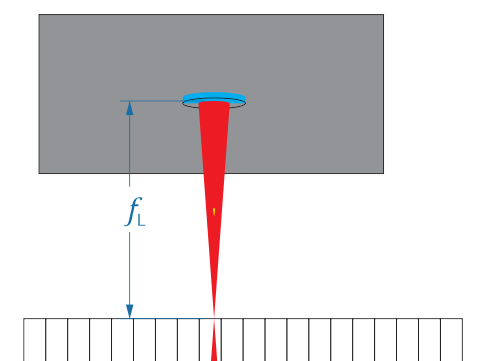

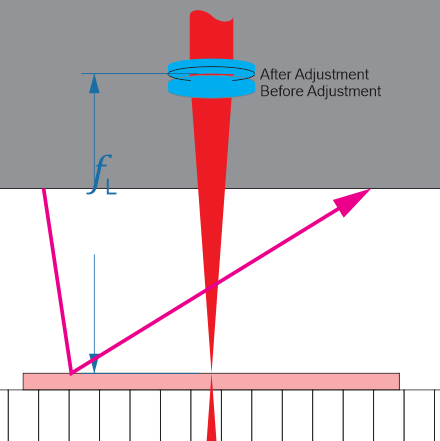

When the system goes through the calibration cycle after you turn it on, I would say that the lens system is verified and zero’d to a known internal reference. Let’s say that zero places the beam convergence at the top of the crumb tray.

If we place an 1/8" piece of material on the tray, enter the material and focus to 0.125.

Then the focal length offset is Zero (0).

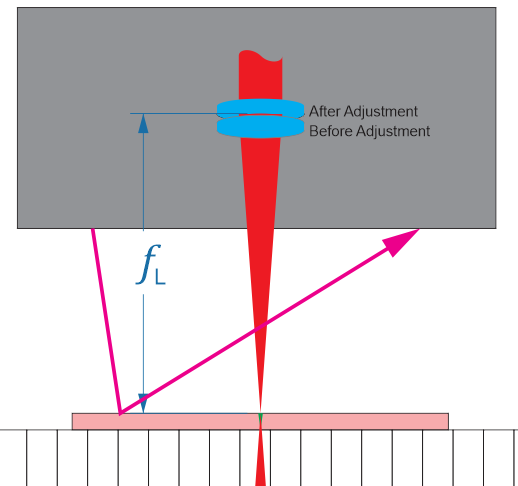

The red laser scans the material and calculates the actual height of the material.

If we were to set the material thickness and focus height to 0.500, then we would expect:

However when the red laser scans the material and finds the true top, which is actually 0.125 above the crumb tray,

and then resets the focal length placement based on the FL offset (0.500 - 0.500) or Zero,

so we end up with something like this.

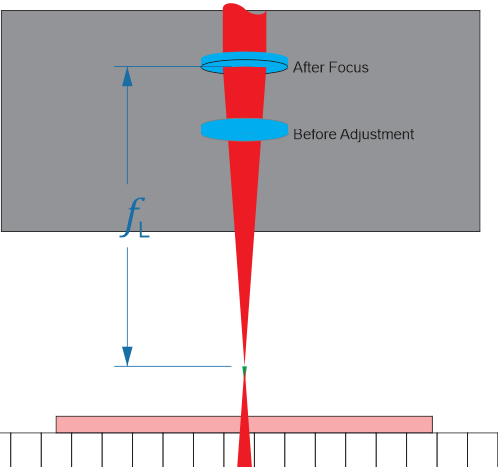

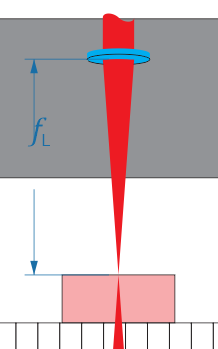

Let’s try a new test:

I have a file that will score the outline of the word Glowforge.

In the UI, I will tell the system that my material is 0.500" thick,

and my focus height is 0.500".

S125|P11

This would mean that I want the laser’s convergence to be on the top of the material.

So we should have something like:

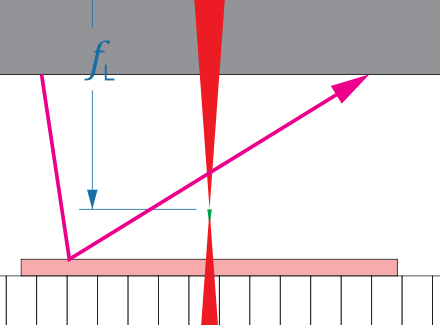

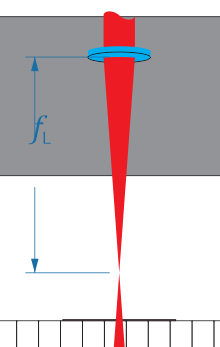

Now, instead of 1/2" material, let’s place a sheet of 0.01" cardstock in the machine.

If the red laser measurement is ignored, then the beam should look like this when we run the job.

The beam would be at the systems maximum divergence, and the score width would be very broad.

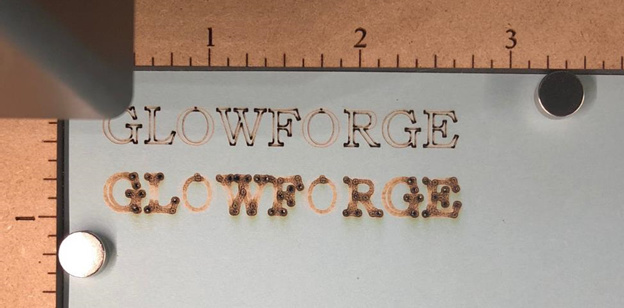

Below are the results:

The top line of text settings were as defined above: Matl Thk = 0.5, Focus Ht = 0.5.

But instead of 1/2" stock, I placed a piece of card stock.

I believe the first line of text is crisp/sharp because the red laser is adjusting the setup based on the actual distance to the top of the material.

The second line of text settings were: Matl Thk = 0.01, Focus Ht = 0.5

The second line is out of focus, because we told the system, the correct thickness (0.01"), set a focus height that was 0.49" above the surface. The red laser set the true top of material, and made a focal length adjustment (0.5 - 0.01) so the point of convergence was 0.49" above the part.