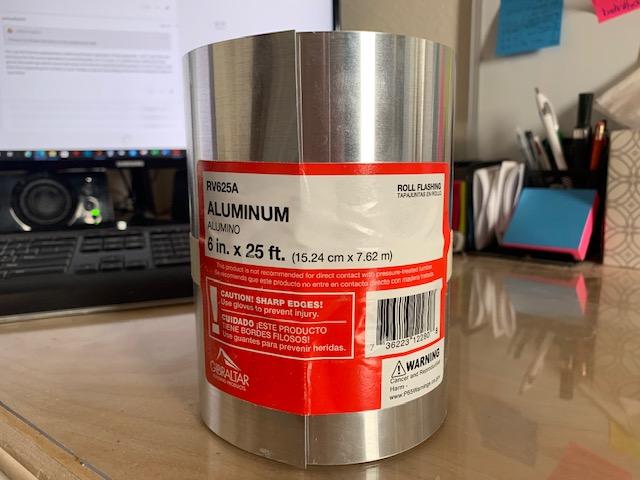

I have some aluminum roll flashing very thin that I want to cut out small pieces on the Glowforge and looking through all of the topics I didn’t see what I was looking for. Is it possible to do this? What would the settings be, and would I need to mask it? I am still fairly new, but this is the 1st time I would try aluminum, this is the roll flashing from Home depot that you get in the roofing department. I will try to attach a picture of this material for any help and suggestions is always greatly appreciated. I am trying to cut small gear pieces for my steampunk clocks.

A 40-watt CO2 laser like the Glowforge won’t cut metal.

… won’t even cut aluminum foil.

Cut from another thin material, and paint them. You can also get metallic-colored acrylic.

Better to cut something else and paint it as here

Another possibility is to make a press mold but you still have to cut it out with something else.

Good point. Several members have used the GF to make molds for low-temp pewter casting. Search will find many posts, but this one started it all, I think:

Thank you all for responding, unfortunately not the answer I was looking for. I thought when this was advertised and I bought it, it did do very thin aluminum or metal?? I am not casting just trying to cut very thin flashing for small gears is all. Can anyone make a suggestion? I do have the Inventables CNC machine as well. Thank you again to all of your help

Nope, that was never a claimed capability. As stated, 40W is nowhere near enough to even mark the surface of metals (although it can leave marks with coatings or dyes…)

You need at least 300W to cut even the thinnest metal, probably 1000W with gas (Oxygen) to cut that flashing.

You might give Inventables a call. I talked to a nice guy there that recommended derlin as a durable lasererable plastic for the gears I was making.

EVERYONE whom the glowforge is their only smart tool needs a trim router and to learn pattern cutting.

This is a great project for pattern cutting.

Glowforge content : you can cut out your patterns on the glowforge.

This die will cut gears. All you need is a die cutting machine, or you could probably do it with C clamps:

Sizzix, Multi Color, Thinlits Die Set 661184, Gearhead by Tim Holtz, 22 Pack, One Size https://www.amazon.com/dp/B01AMLGERE/ref=cm_sw_r_cp_tai_H-rmFb5ND2D0K

Not from aluminum flashing. It’s thicker than a tin can…

Oops. I’ve used those dies to cut very thin metal, guess flashing is not thin enough. However, there do exist thicker dies that might do the job although probably more costly.

These questions come up now and again, and I always flash to the terminator.

“Just what you see pal”.

Maybe advertised as “marking” anodized aluminum.

It’s also pretty clear on the web site:

Glowforge can etch some metals, like anodized aluminum, directly. Other metals, like stainless steel, work best if you spray them first with a product such as Cermark. This process discolors the metals but does not engrave them away, so the surface still feels smooth to the touch. Unfortunately the power levels of a desktop machine aren’t quite enough to cut metal, so your best bet is laser cutting a template or jig, then using that as a guide for a blade or saw. You might also consider a Bantam Tools Desktop PCB Milling Machine or X-Carve instead of buying a Glowforge. These are desktop CNC machines that can mill out soft metals. We want to be sure you get the right tool for what you need!

Aluminum flashing is probably softer than aluminum cans and reading about it, will cut cardboard thicker than the flashing. If someone gets it working I would like to know as I have both aluminum and copper flashing ![]()

![]()