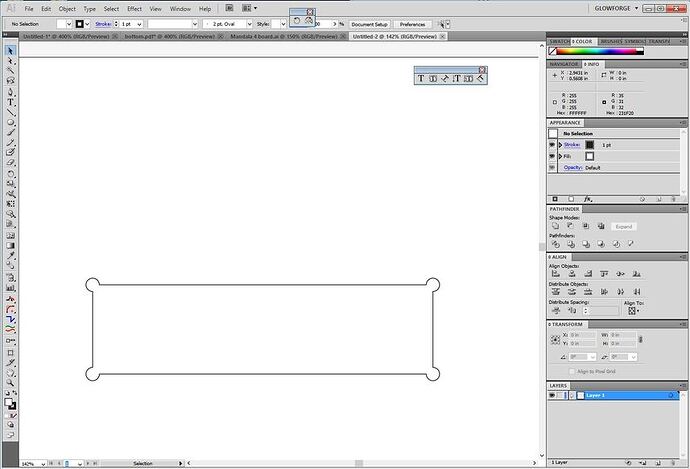

I engraved this shape on 1/8" iridescent acrylic from Houston Acrylic with the Medium Black Acrylic GF setting and not really sure how to avoid this. I put masking tape on the top before it’s engraved, and it doesn’t always do this on my iridescent cuts. Any advice would be helpful! Thank you

I engraved this shape on 1/8" iridescent acrylic from Houston Acrylic with the Medium Black Acrylic GF setting and not really sure how to avoid this. I put masking tape on the top before it’s engraved, and it doesn’t always do this on my iridescent cuts. Any advice would be helpful! Thank you

How about manually dropping power by say 10 points, see if its just too hot - or the material is too close to the laser, there are too many factors, but usually cracking is heat related.

Did you clean it with alcohol?

If so the concept is called crazing.

Ahhh! Unfortunately that’s common in acrylic when you have the design come to a sharp point. (Like the crotch there.) The acrylic is under stress, and when you hit it with too much heat, (the beam pauses for a split second longer when it has to come to a complete stop and back up), it can develop splits or cracks at the point.

You can apply a design device called “dog bones” into your corners…basically it’s a tiny circle that redistributes the forces and keeps it from splitting. Or you can try rounding that corner…it might be enough to keep it from splitting.

Annealing (e.g. in your oven) after cutting will also relieve the stress permanently. Lots of discussions on this if you search the forum.

Yes I did! Wow that’s crazy, I would have never thought alcohol could do that!

Oh wow this is probably the reason as well, along with putting alcohol on it :o . I tried looking up what “dog bones” was and an example of it but I didn’t find anything other than people trying to make dog bone shapes in illustrator  Would you happen to have any links about it?

Would you happen to have any links about it?

Ugh…no that was five years ago now, I’d never find it again. It’s just a tiny circle…I use them in my acrylic designs… on a rectangular box they look like dog bones…hence the name.

Hang on…

(You can actually probably just get by with rounding that corner, so that the head doesn’t pause in the motion plan…I had good luck with that on some tight corners in acrylic.)

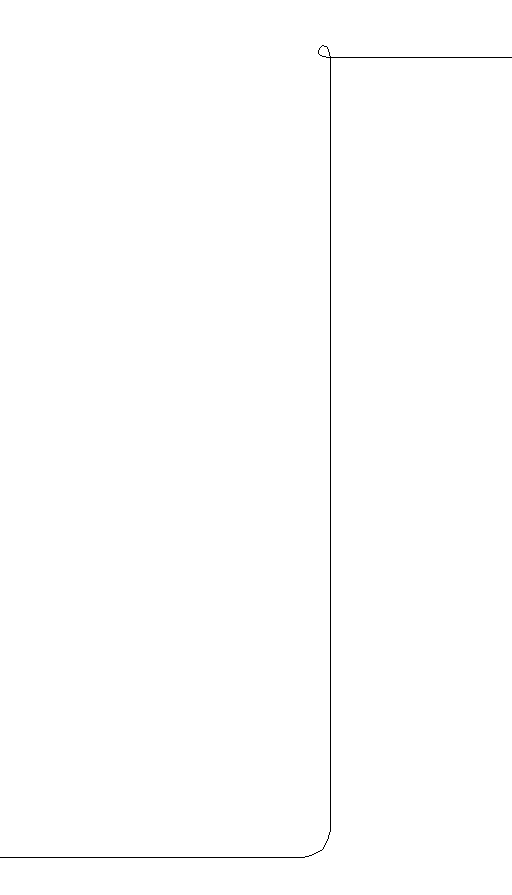

boxes.py makes their corners like these. inside corners on top, outside corners at bottom. it’s very subtle. that vertical line is 3mm zoomed in.

Nah in this case it’s all the alcohol. That heat stress thing is real but wouldn’t apply here.

Alcohol as rarely sold as just one type. If it is only ethyl-alcohol there is a big tax and it is sold as booze. To avoid the tax other alcohol types are added. many cause no damage to acrylic, some soak in and cause it to swell, and some cause major crazing. I have had experience will all of these things, but when it works it dissolves the masking adhesive nicely and washes away any crud from cutting as well. The trick is to test, test, test, preferably on scrap, before committing to any final cutting, so all of your surprises happen to your scrap.

Happy Cake Day.

Wow it sounds like it actually behaves like steel! I guess the principle is similar.

This is also happening to me and I have NOT used alcohol. It’s only the iridescent ones that do this.

That could be a clue. The alcohol reacts on the surface so perhaps the Iridescent coating does the same when heated? I would want to know what the material chemistry was as there are some that could destroy your machine as well.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.