Will Glowforge have the ability to use as a source file for cutting, a 2.5D CAD part (as in a flat part with height with specific dimensions) from an “stl” file format generated by a source application such as Solid Works, Cubify Invent, Fusion 360, etc.?

@jdodds regardless of whether the glowforge will accept .stl directly, it is probably not a good format for the task.

STL is designed for triangulated surfaces, and you would be better off with a format designed for (or more accepting of) 2D.

Examples might be SVG, DXF, EPS, or PDF.

For 2.5D engraving you are probably going to need a raster format that handles gray scale height maps, or a hybrid format like SVG or PDF.

There is what I hope is a preliminary list here: What file types does Glowforge read?

@dan I would love to see a definitive list of what you will be supporting either “natively” or via plugin of some sort.

I am interested in cutting 2D parts with very precise dimensions, radii, cutout slots and circles etc. with features located at very precise locations on the part, a task better performed by a CAD application (IMLE). “Draw” programs are not well suited to generating these parts with very precise layouts (IMLE). I’m not thinking about engraving aspects of GW with this question.

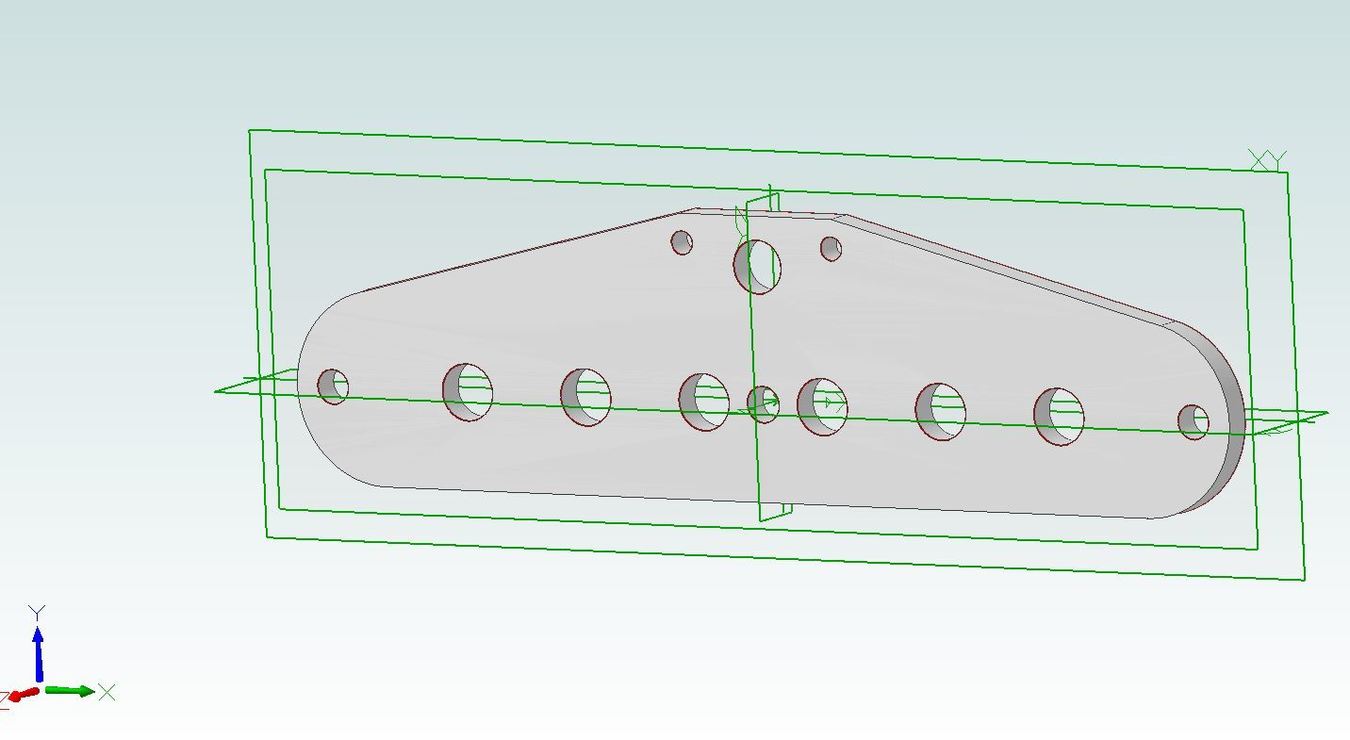

This part:

From an stl file dimensioned something like this:

Fair enough, but I would still think you are better off not using .stl

DXF in an interchange format that is very well supported by most major CAD packages (it was invented by Autodesk for exporting from Autocad way back in the dark ages).

It will do everything you need, and best of all it is on the list!

@jdodds I get where you’re coming from. Thankfully there are some good workarounds. For example, I do a lot of mechanical design in Sketcup (not the best program in the world for it, but I’ve been using it since day 1 and I’m super efficient, and it’s free and runs on my Mac, unlike Solidworks)

To get accurate parts I lay everything flat, switch to a topdown “Parallel Projection” view that shows all my parts and then draw a flat rectangle around everything. I then set that rectangle to a very specific known dimension. For example, 15.1234x15.1234 and export everything as a PDF using print to PDF.

From there I import the PDF into Adobe Illustrator, select the rectangle and all my parts, and then set the scale to 15.1234x15.1234

The result is parts that are accurate to 4 decimal places, which for most of my mechanical assemblies is good enough.

It’s not an ideal workflow, but it gets around Sketchup’s refusal to include vector output from the non-pro version, and produces accurate parts.

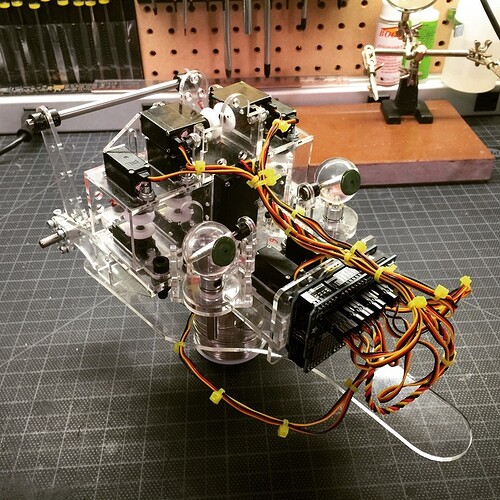

Here’s a sample of a laser cut acrylic assembly for the mechanical core of an animatronic that was designed in Sketchup and exported using the steps listed above.

I’ve cut from both AutoCAD and Adobe Illustrator (and rhino but that was a joke). I prefer AutoCAD because you can draw 1 to 1 then export to did for print. Very precise and if you are conscious it’s easy and everything is to scale. Definitely agree not to use stl.

I should add that I didn’t cut directly from the program’s just used it to design and export for print

Yup. STL is not the format you want for this part. If you have Rhino you can design in 3D if you like then use the “Make2D” command to get the projected 2D paths, save to SVG and you’re good to go. I avoid DXF because it is a messy and highly fragmented format. SVG works well and compatible with most vector illustration programs but will ultimately depend on how good the GF’s parser will be.

I find all this “what format/applications” to use for laser very interesting. I have a 3-axis CNC router and have followed the Maker side of things for a bit (in an observation kind of way). I see both those 3D formats as built on precision CAD, notionally at least. One an “additive” technology and the the other “subtractive”, but both built on CAD stl parts and precision. Then there’s the laser, which is in so many ways is marketed as a “hey, don’t worry about CAD and all its related precision software, just draw something and print it”. It just feels so contrary for making “parts” compared to either of the other 2 technologies. It just feels weird to want to build from that CAD premise approach but being told you have to jury rig that result to make it happen in this technology.

Hey, don’t get me wrong, I’m in for a pro, I just really wanna use CAD to design parts, not a Draw app. I hope someone recommend a good therapist. . .

I don’t think anyone is saying you have to use a “drawing” program, or that there is anything jury rigged about this.

A file format is just a way of transferring data, and usually it just does not matter which format you use.

Don’t get hung up on it, and concentrate on finding a tool that works for you.

Almost ALL the major CAD applications can export multiple formats, and in general as long as it is able to handle vectors, any file format will do.

Every major CAD package can save in a format that Glowforge can ingest. @jdodds, you can design in any of the three CAD packages you mentioned and save in a Glowforge-compatible format.

What CAD software should I use? Thanks Dan!

Fusion 360 it is then. . . I’ve had it loaded for a while now and can certainly can come up to speed on it enough to do anything I could ever conceive of. Thanks for everyone’s input. ![]()

Excellent choice. That’s what the rubberband launching drone was designed in, in fact. It outputs SVGs, which are perfect for Glowforge.

@dan. Fusion 360 does NOT save or export to SVG.

I would LOVE to say “I stand corrected” on this one.

I’ve been using Inkscape for years after leaving an education setting that had provided CorelDraw of happy memory and Illustrator. Never paid too much attention to the plugins and extensions since I was doing 2D graphics (mainly homebrew bottle labels). I’ve checked the Render > Gear extension now and also the Lasertools tabbed box maker and am really energized on this. Having been a big fan of Mathias Wandel’s woodworking site, I’ve been wanting to put his gear creations into practice. Never done the laser cutter before so figuring kerf and relief will be fun. Going to lurk and poke around until I find the specs on the base. Reading up on carbon filters and air flow. May be be ready to fabricate an air filter add-on to the basic I ordered.

You are correct Fusion 360 imports but does not export SVG.

It will export DXF though.

I would recommend autodesk 123D Make it a can take a 3D model and covert it into different ways of assembling something out of flat pieces. I think it is one of the best combinations for our Glowforges.