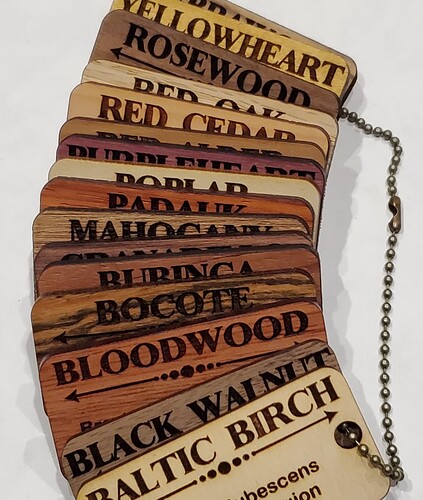

I figured one way to use up small scrap pieces of wood and keep track of the boards in inventory. still have some more to do and all of the veneers. About a third of the lumber was resawed down from doors, damaged furniture, pallets and scrap to 1/8 in. to use in the Glowforge.

Sigh, here’s me bunging another piece of MDF in the machine.

It is very hard getting any of these interesting woods in the UK

So wonderful you’re able to repurpose so much. Gorgeous samples!

Great use of the scraps!

you should engrave your settings on the other side.

Such a great idea!

Did you finish the wood afterwards?

That is an impressive amount of organizational work.

Those are great! Nicer than the ones I bought (scroll to the bottom).

My biggest problem is looking at 6 pieces of white wood and figuring what species each one is. If the color or banding is there it is much easier.

Reading your list I see that there is a couple of interest. Mahogany is these days several species as the original Cuban old forests are gone, mostly tropical. Yours is usually called Mountain Mahogany though harder and heavier than the original. I had not realized it was a wood of the North American West.

Rosewood is another tricky name applied to many species though I read that yours is a cousin

That is a good idea. I used one setting for the hardwoods, one setting for the plywood and one setting for all the softwoods.

No, The wood just went through the planner then sanded.

The Mahogany came from 1/8" door veneer and was stamped Western North America on the back side.

The rosewood I have is marked “rosewood, bolivian” not part of the rosewood family just in name I think

Nice! I need to get myself some purpleheart eventually. Looks great!

Interesting

Pau Ferro | The Wood Database (Hardwood)

I would love to find a way to do this ![]()

How cool!

That’s a pretty great use of small scrap! I really need to get back into resawing my own material. I have a small woodshop but all of the tools needed to do it. I just need to make it a priority I guess.

I used that to make a catchall tray for my son’s Christmas present. (I’m working on a Stratocaster for his birthday)

It’s finished with Rubio Monokote Clear - the wood was more brown than red but has reddish highlights that are more noticeable in person. It has a richer tone than walnut even though the overall brown tones are similar.

That is truly gorgeous

I like Rubio as a finish. It’s an oil finish but has a chemical activator that speeds the hardening from days or weeks to 24hrs. Typically a matte finish but can be buffed to a high gloss.

The Strat will be made from cherry though - the bolivian redwood is too dense to provide the intonation. Cherry is closer to traditional materials like ash or mahogany. The finish in that will be a lot of lacquer - usually takes 30 days with a new coat every day or two.

When you get into that it gets nuts. One big surprise for me was how much having the wood under tension made a difference. That little bent box is just oak plywood but because it is under tension from the bend it is amazingly clear and loud.