Just wondering…what is the thickness of wood/other items most of you usually choose to cut? I know that I can cut wood up to 1/4 inch thick, but I am seeing that most people gravitate towards using 1/8 inch thick. Is this considered the “standard”?

i would say 1/8" is most commonly used. but what’s right for your project depends on the project itself. 1/8" can be a little more forgiving when making boxes than 1/4", which is why i use it more often. but i’ve used as thick as 1/2" hardwood (which has very heavy charring on the edges).

@shop, with excellent advice as always.

Another thing I’ll add is that not all 1/4" woods are the same. 1/4" balsawood can be cut easily, but 1/4" ironwood or sapele is not nearly so easy.

As with any new material it will be necessary to test for settings – there’s not a one-size-fits-all, thickness can vary, wood growing conditions can vary , etc – so a core skill is learning how to efficiently test while not using too much of your material. Check out #6 here for my method:

Have fun and experiment. If you’re unsure about a specific wood, just search the forum for it. Take Zebrawood, for example… looks great, but @rbtdanforth will tell you some stories about it. Or Black Palm… gorgeous and unusual, but almost always “stabilized”, meaning it’s impregnated with a resin that is difficult to cut. (ask me how I know, ugh)

Welcome to the forum, we love new people and new projects. ![]()

this is true of 1/8", too, when you get to your other examples at the end (zebrawood or black palm).

as always; test, test, test. if you want to try something new that may be difficult, get the least expensive piece of it you can and test first. most exotic wood sellers sell 24" long boards, so you’ll have to cut that 4" off the end first. that’s good testing material. and as @evansd2 said, you can search here to see if someone’s worked with it before and what their experience was.

I have and still do cut a lot of stuff that is 1/4 inch or more. If one intends to do relief engraving, 1/8" wood can be pretty thin after you have engraved away 3/32" of it and still it can look pretty shallow. If you are making a box as a 3" cube 1/8" wood works well, but in an 8x10" box 3" tall 1/8" wood looks pretty thin.

There are many different species of tree sold as mahogany and some work terrifically. But some species are extremely flammable and will turn to ash while you cut it. Nearly as bad is Zebrawood, that with great difficulty I have engraved by keeping it wet. I have also had Ash turn to ash trying to engrave it.

Even Walnut that at its best cuts very well barely scorching under the highest power, I had two pieces that were almost as bad as Zebrawood and ruin the pieces I was cutting. If they were farmed trees vs old-growth or what I do not know but the only clue was that they felt lighter than they should have been.

Even on each new piece of wood, you have a choice. do you test it with a small bit, to see if your expectations are met, or do you test the whole piece with that design that is so critical it comes out well? How wildly lucky do you feel?

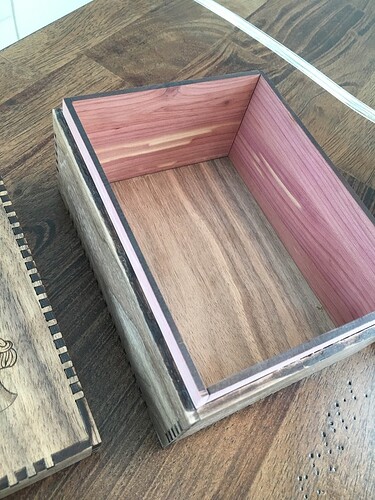

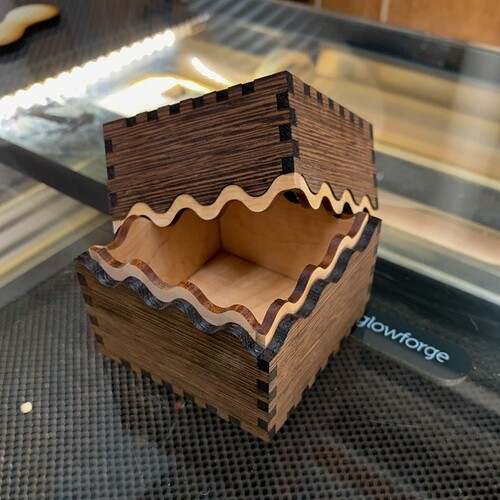

this depends on how you make the box. if it’s just the 1/8" in total, then maybe. but if you do a slide stop lid, where there’s an additional 1/8" liner inside that sticks out above the edge for the lid to slide over, it’s still 1/8" wood you’re cutting, but it’s 1/4" thick total.

as long as you don’t engrave all the way through the 1/8, if you then have a 1/8" insert inside, you add the stability back.

neither is wrong, both have their advantages.

the first box i showed is walnut with a cedar lining. the second is wenge with curly maple lining. that gives you two-tone wood, which could be interesting, along with the sliding lid. and in the case of the walnut/cedar, and aromatic interior.

working in 1/4" is less work (but slightly less forgiving if you’re looking to have some pressure fit on the fingers).

1/8 and Purebond 5/32 here, with just a handful of exceptions. 1/4 was just too unreliable to mess with (for me).

i think some of this depends on what wood we’re talking about. if you’re talking plywood, then 1/4" becomes less predictable. if we’re talking hardwood, i find far more predictability (within the same species).

In general I have found the thicker wood stronger (at least on the end grain) and if a hair “too loose” still holds well while the thinner wood has a much smaller range and the edge grain fingers more likely to break. I often use the thicker wood for the lid as I can go really deep on the engrave and with a rabbit corner the bottom of the engrave can be below the edge of the box.

The lid there is 3/8+ Walnut I think.

I didn’t say it was unsuitable, I just answered the OP’s question of what I choose to cut. I was never happy with 1/4" cuts on either hardwood or ply.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.