Running into an issue where my engraved pieces are:

a) drifting to the right .1 - .15 every time I do the same work in the same location, without change set focus etc.

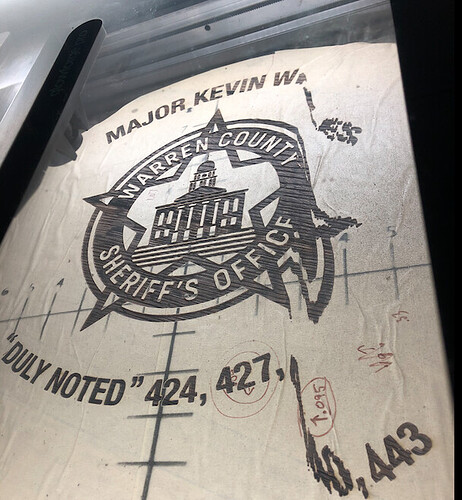

b) the design will scatter itself from left to right smearing the work and rendering it not usable

c) the camera calibration will run and say: "Not completed the process was interrupted, so no changes were made to you calibration.”

(maybe X-Axis Stepper Motor? but how)

d) the laser head resting place slowly creeps more to the right of where it should be, maybe why the design is also creeping to the right

e) One thing I have accidentally done and made sure to correct is not using properly flat material when running the camera calibration print, I have noticed it saying the the “Calibration has been interrupted” which hints to physical nudges etc. but unsure what else may cause this.

I have taken off the carriage plate and replaced it with a new air assist fan and carriage plate that I had been sent for a previous machine that ended up malfunctioning from something else and was sent back, as a result, this is my 3rd machine…

(needing something realize and this has just been a headache, orders getting pushed back again)

Since I replaced the carriage plate/air assist fan, I had thought it may correct the issue.

I am 99% certain this is an X axis only issue.

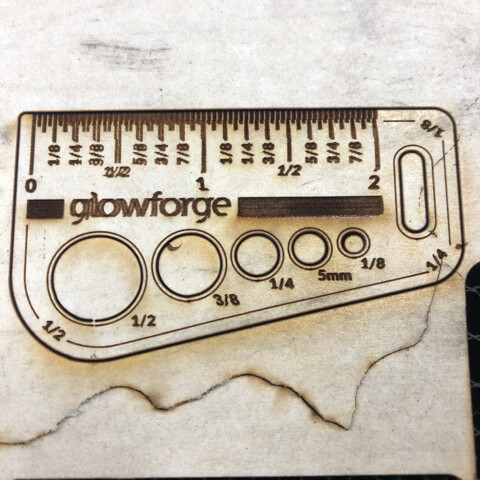

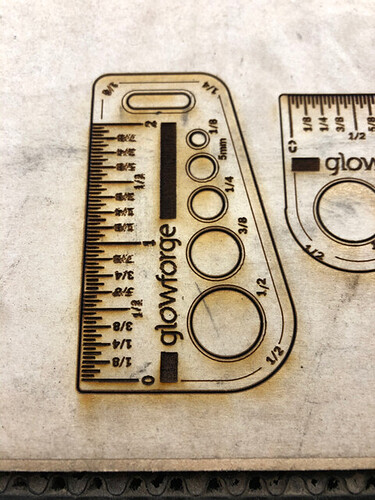

Attached you will find pictures of the “Gift of Good Measure” file as well as a custom piece I was working on. (height is not the issue as the materials are flat and short enough)

As we all know, the “GOGM” file in itself will not have any issues as it has been perfected and is a tried method to mitigate file errors.

In these pictures and examples I have printed the “GOGM” Horizontally as well as Vertically to confirm that it is indeed the X Axis.

Up until most recently, whenever I have done cleaning etc. , I have removed the carriage plate and air assist fan as you would a bicycle chain, not disrupting the right pulley wheel at all. (I noticed this trouble prior to loosening the wheel)

Only until the last time or so have I used an Allen key and actually loosened the wheel and worked to have the best tension in the cable as possible when retightening, watching the step-by-step tutorial.

Other things to note as to mitigate other possible problems; I use an air compressor and rubbing alcohol to clean, I have applied a single layer of packaging tape on all of the exposed white parts, as to red

uce the mess, making sure none of the tape gets in the way of any moving parts etc.

Would love any and all help and truly appreciate the forums help!