Lots of mixed data on laser cutting foam board, so for those that are interested in using XPS, Yes it cuts great! Here is some info:

XPS is extruded polystyrene foam, its most often seen as the blue “Styrofoam” or pink “Foamular” rigid insulation foam you can get in building supply stores.

EPS is expanded polystyrene foam made of lots of little foam pellets that is most often seen as packaging or as the material in cheap coolers. EPS is what most people think of when they think of “Styrofoam”, but really that is just Dow’s brand name for both XPS and EPS products.

XPS has a bad rep on many laser lists and is often sited as producing cyanide gas and bursting into flame.

Neither XPS or EPS will produce the cyanide gas that you get that you get when you burn ABS or the corrosive chlorine gas from cutting PVC foam… which can be found in many but not all foam boards. In fact it produced less smoke than it does with my hot wire cutter and I’m kind of pissed that I waited so long to experiment with it. Im not saying that it’s a healthy alternative to air, but I didn’t notice a smell and it’s not cyanide. If you are not sure what foam you have, don’t cut it, and if you ever see a green flame then don’t breath.

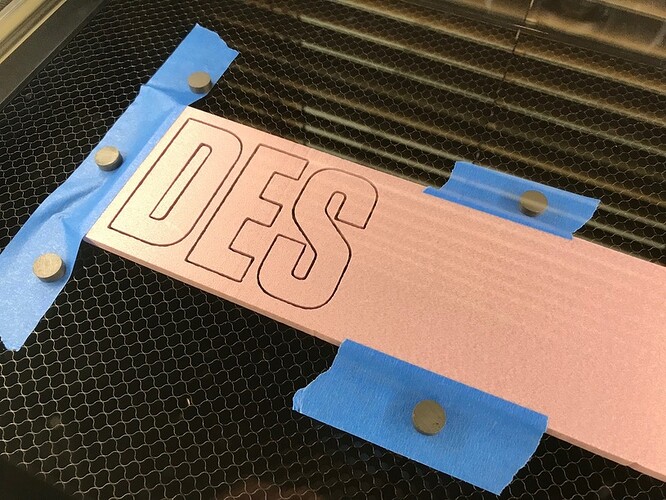

These 8mm thick letters were cut on a standard GF with the power at 20% and the speed at 225

With the power at 20% and the speed at 500 the cut goes about 2mm deep. Going much over 20% makes the kerf wider and more ragged than I liked,

The kerf on the top of the board is about 1mm thick, as it punches through the foam it produces more of a scooped out edge than you would get with a hotwire cutter. I don’t think I would go thicker than 10mm, Im guessing the fire hazard may become more of an issue when you are trying to cut thicker sheets.

Here is my title after sculpting and painting the foam with some quick weathering techniques, now I need to shoot it with a macro lens and I saved myself a day in z-brush modeling it… until they change the font on me anyway