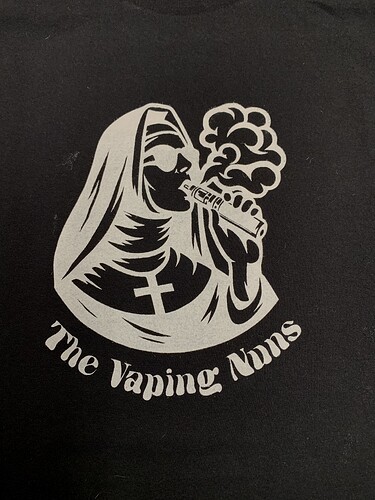

Ok, first tshirt. My squeegee technique needs a little work, but after running a sheet of card stock to load the screen, this was my first attempt. And if this is my baseline quality from my first shirt, I think I’ll be happy as I get better/more efficient.

Awesome! I love it!

It has been 20?-30? years since the last time I used a screen printer but it was a cool trick. It was a ceramic group of potters (I think they had 20 potters’ wheels and a huge oven. and much more). They used a “wax” that was soluble in water unless exposed to UV radiation so it was set in the sun covered by the design and the result was the screen.

The cool trick was that we printed it on paper with a cobalt stain and then carefully wrapped the paper on the curved ceramic bisque (in my case a huge bowl full of dragons ) All those blue porcelain vases suddenly became obvious how they were done.

Can you purchase extra screens, or better question can I purchase the screens /frame without buying the tool? Their materials website likes to auto refresh then error out on my machine.

i think they’re only just becoming available now for purchase. i got an email earlier this week w/a code to get a discount off of them for now.

i was just coming to post taht after i went back to my email. that’s the right link.

I ordered some to be shipped to my brother-in-law to be re-shipped to us since they won’t mail it to Hawaii. Since this is a pre-order I wonder if it is something that I can make utilizing screen from Amazon and some laser safe substance. I wonder what that substance could be.

Since I would only be making one or two shirts it probably wouldn’t need to withstand the usual abuse a screen printing screen would go through.

Wondering if this screen would work:

https://www.amazon.com/Stainless-Steel-Filter-Screen-Filtration/dp/B07QNTQ13L

i don’t think it’s about the abuse from screen printing. it’s about how fine the mesh is. and it probably depends on how clean and crisp you want/need the print to be. just from looking at them, since i don’t know the numbers of the xtool one to compare with those numbers, the xtool screen looks like it might be a little finer than that. you also need it to be a smooth mesh, and that one looks like it may be. if it’s rough, it won’ sit completely flat on the material and ink may bleed under around the edges.

biggest issue right now is we don’t know exactly what they’re using as a substrate inside the mesh. and i don’t know what to suggest you use.

I was thinking of something like a can of shellac or lacquer just to fill the holes. they have a finer one:

https://www.amazon.com/gp/product/B081QB3BLF

might be fun to test.

i’d be curious to see how it went. you need something that will stand up to pressing the ink through the rest of the screen that’s engraved away. wonder if there’s a way to just put the photosensitive filler like they use in regular screens and use that. might have to “develop” the whole screen first, then engrave away the area you want to print. just not sure what is in that filler.

I have plenty of that photosensitive filler, just wasn’t sure if it was laser safe.

and neither am i. not sure how easy it is to find an MSDS on it.

My xtool screen printer thingy is still waiting for me in the box. I appreciate all the trail blazing you people are doing.

I have been using my xtool p2 quite a bit. Thus far, I slightly prefer it to the GF due to speed advantage and reduced smoke residue (masking? what is masking?) . If is perfect? no, but it is very nice.

I’d definitely go with the 120 or 200. 80 would be a messy print.

You could try heat pressing Eco Iron On/HTV. If it sticks well enough then laser your image in reverse as you’ll want to print with the HTV side facing down. It would be even faster to score the HTV first, weed, then apply to the mesh.

Using regular adhesive vinyl applied to silk screen mesh is a pretty common down and dirty way to make short run screens.

Great idea! Thank you! I have all of the screen printing stuff in the garage which fell by the wayside when the laser came home.

Catching up reading the forum. Folks are so helpful here especially when it comes to discussing new tech

1000/70/270

[

The lacquer had a more even spread without holes with 2 coats each. (though maybe that’s just me)

It burned off the screen with your settings pretty well. I think it will work. I will test a screen print at some point. ![]()

@ekla I have found that my love for weeding is very low after using the cricut for years. So much easier to throw in a screen and hit go.

I haven’t used mine yet. But I had been wondering…

What would be the difference between using this and making a template?

(Other than the type of colorant used, like the ink vs paint or something)

There was a project I was considering trying that I wouldn’t want to use up a screen for. I was thinking of just making a template and using dye or fabric paint.

I think I need to experiment.